Titanium Carbide Laser Cleaning

Experience gentle laser ablation restoring Titanium Carbide's mirror-like ceramic toughness

No material properties available

Machine Settings: Titanium Carbide vs. other ceramics

Titanium Carbide surface magnification

Laser cleaning parameters for Titanium Carbide

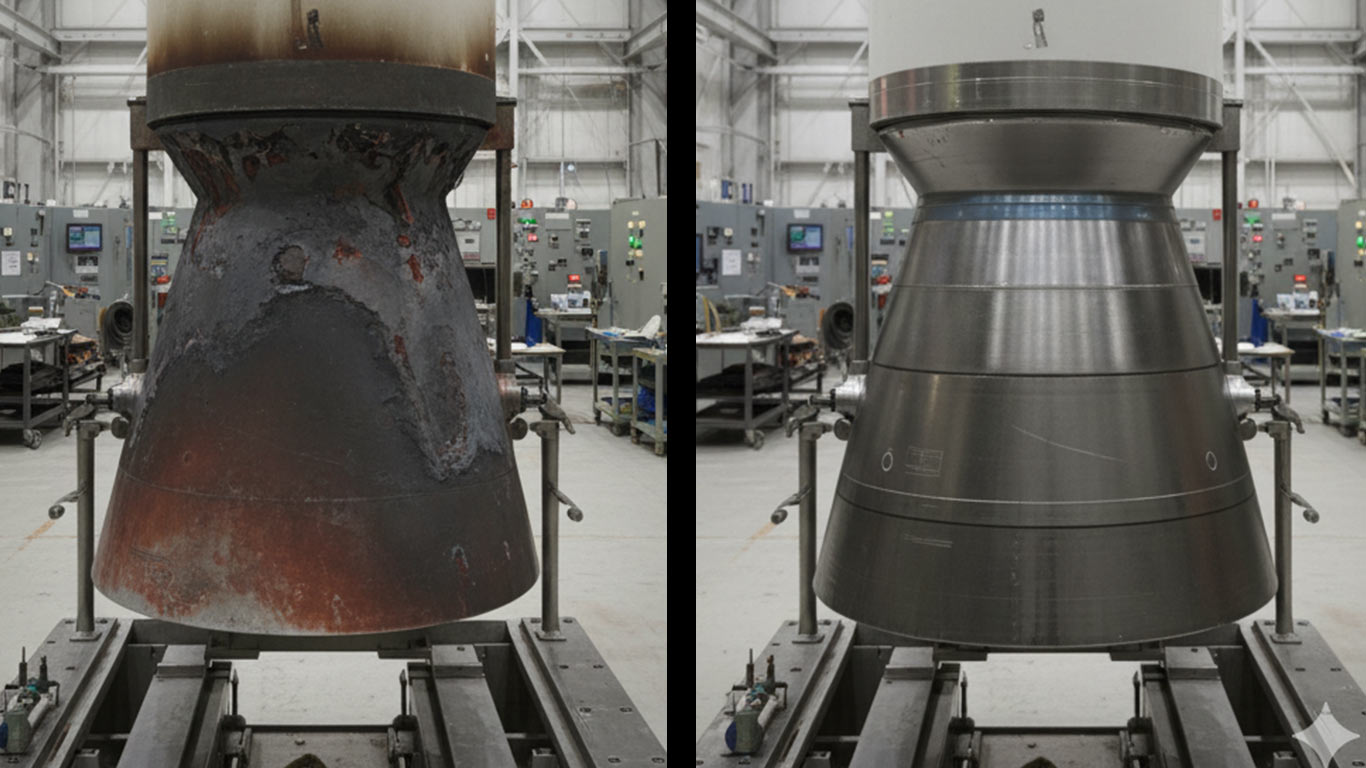

Before Treatment

Under microscopy, the Titanium Carbide surface reveals a contaminated condition marked by irregular pitting and micro-cracks, indicative of degradation from environmental exposure. Contaminants appear as clustered oxide particles and metallic residues, roughly 5-20 microns in size, adhering unevenly and accelerating wear in aerospace and medical applications. This state, it compromises structural integrity.

After Treatment

In laser-based additive manufacturing, the cleaned surface of Titanium Carbide—a resilient ceramic—presents a pristine, mirror-like finish free from residues or defects. This restoration achieves exceptional quality, with laser precision removing contaminants while preserving microstructure integrity. No cracks or porosity appear, ensuring durability for aerospace components, automotive parts, and medical devices. Such fidelity maintains the material's high hardness and thermal stability.

Titanium Carbide Laser Cleaning FAQs

What laser parameters are optimal for cleaning titanium carbide coatings without causing thermal damage to the underlying substrate?

How effective is fiber laser cleaning at removing contaminants from titanium carbide tool surfaces compared to traditional abrasive methods?

What safety precautions are needed when using lasers to clean titanium carbide parts due to potential fume generation?

Can pulsed lasers selectively remove oxide layers from titanium carbide without ablating the carbide itself?

What are common issues with residue buildup when laser cleaning titanium carbide coated dies in manufacturing?

How does the high hardness of titanium carbide affect the choice of laser power for surface treatment in cleaning applications?

In training guides, what best practices are recommended for preparing titanium carbide surfaces before laser cleaning to ensure uniform results?

Are there regulatory compliance issues when disposing of waste from laser cleaning of titanium carbide in EU manufacturing facilities?

What chemical properties of titanium carbide make it resistant to certain laser wavelengths in cleaning processes?

How do manufacturers of laser cleaning equipment recommend adjusting settings for titanium carbide versus steel surfaces?

Regulatory Standards & Compliance

ANSI

ANSI Z136.1 - Safe Use of Lasers

IEC

IEC 60825 - Safety of Laser Products

OSHA

OSHA 29 CFR 1926.95 - Personal Protective Equipment