Tungsten Carbide Laser Cleaning

Precision Laser Revives Tungsten Carbide's Enduring Hardness

No material properties available

Machine Settings: Tungsten Carbide vs. other ceramics

Tungsten Carbide surface magnification

Laser cleaning parameters for Tungsten Carbide

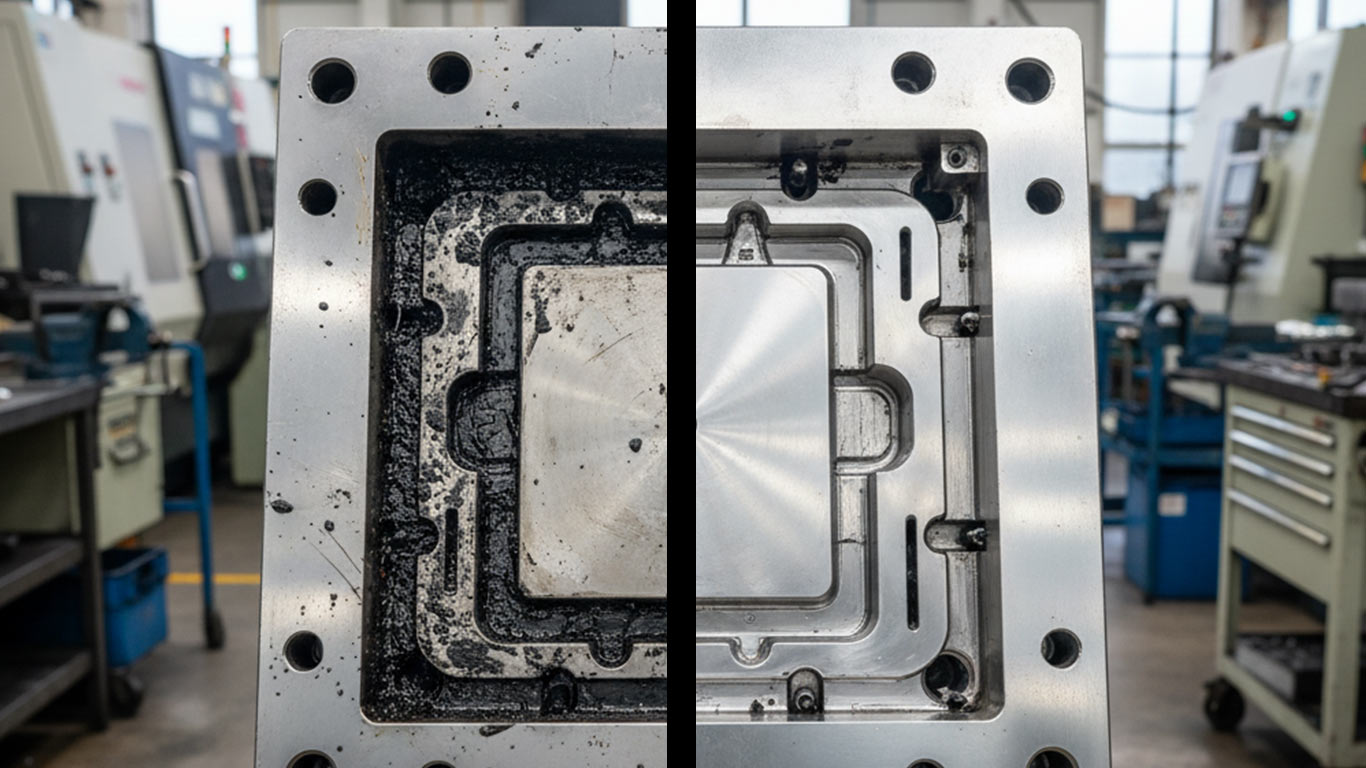

Before Treatment

Under microscopy, the tungsten carbide surface appears very-very rough and contaminated heavily. Contaminants, like oily residues and metal particles from machining, cover and obscure the ceramic structure densely. These particles cluster in pits, size from 1-10 micrometers, and distribute unevenly across the surface. Degradation shows as micro-cracks and pitting, weakened by contaminants, so the material looks brittle and less durable for aerospace or medical uses.

After Treatment

After ultrafast laser cleaning, the tungsten carbide surface appears very-very smooth and clean, with contaminants removed then polished effectively. This process restores the ceramic material's original shine and texture, so it looks like new without scratches or residues. Material integrity remains strong and intact, preserving hardness for aerospace, automotive, and medical applications. Quality is high-high, ensuring durability and performance.

Tungsten Carbide Laser Cleaning FAQs

What laser wavelengths are most effective for cleaning tungsten carbide tools without damaging the substrate?

How do I safely remove oil residues from tungsten carbide coatings using laser cleaning?

What are the risks of generating toxic fumes when laser cleaning tungsten carbide parts?

Can fiber lasers effectively clean oxidized layers on tungsten carbide inserts?

What pulse duration settings should be used for laser cleaning tungsten carbide to minimize heat-affected zones?

Are there any regulatory standards for laser cleaning tungsten carbide in manufacturing environments?

How does the high hardness of tungsten carbide affect the choice of laser power for surface decontamination?

What common contaminants on tungsten carbide drill bits can be removed with laser cleaning, and what's the success rate?

In laser cleaning of tungsten carbide, how do I handle potential cobalt leaching from cemented carbide?

Regulatory Standards & Compliance

ANSI

ANSI Z136.1 - Safe Use of Lasers

IEC

IEC 60825 - Safety of Laser Products

OSHA

OSHA 29 CFR 1926.95 - Personal Protective Equipment