FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

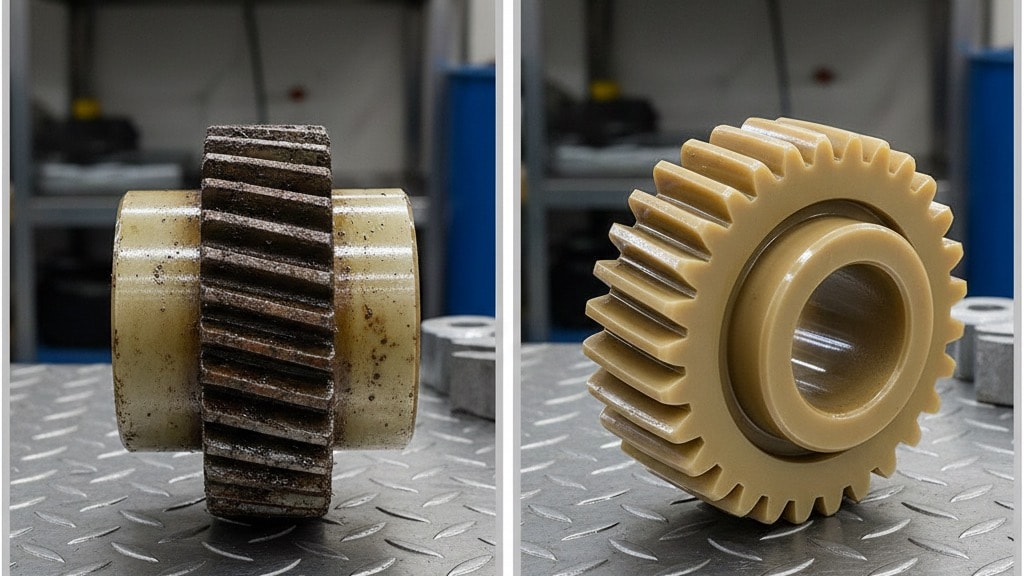

The secret to PEEK's success is its remarkable resistance to intense heat and aggressive chemicals, all without losing its structural integrity, making it perfect for rigorous industrial applications where ordinary plastics would quickly fail.

When examining the contaminated PEEK surface at 1000x, you spot thick layers of debris clinging everywhere. Dark spots and irregular bumps cover the entire view, blocking any smooth areas. This mess creates a rough, uneven texture that hides the material's natural form.

After laser treatment, you see the PEEK surface restored to a clear, uniform shine at 1000x. Smooth planes and fine details emerge without any clinging residues. The treatment wipes away all traces, revealing a clean

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more