FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

When laser cleaning polyimide, consider its exceptional heat resistance, which maintains stability under intense thermal stress to prevent warping or breakdown—problems that affect lesser plastics—and lets you achieve a clean surface without compromising structural integrity.

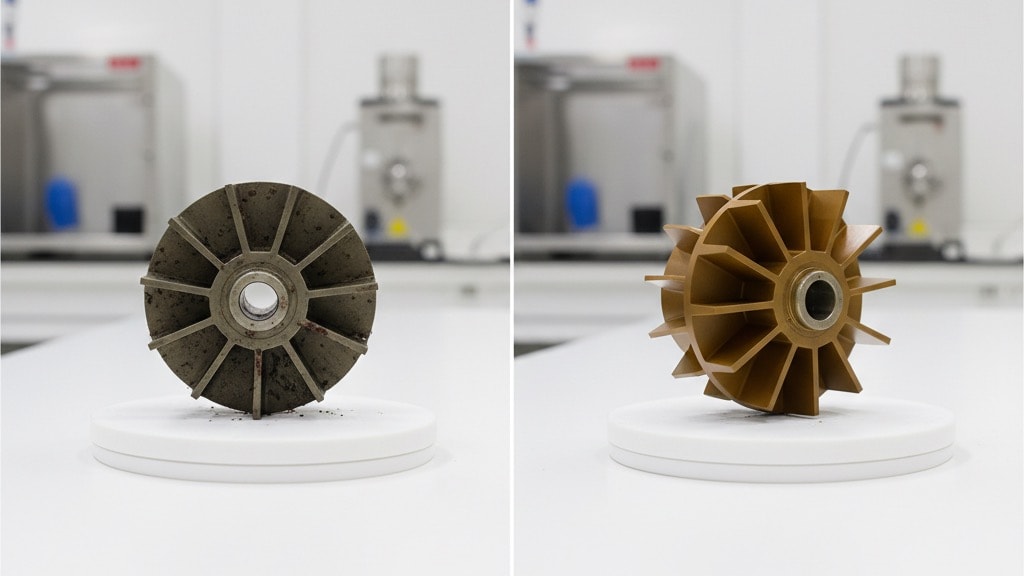

At 1000x magnification, the polyimide surface looks cluttered with scattered dirt particles and sticky residues everywhere. I've seen how these contaminants form uneven clumps that roughen the entire area. They hide the material's base texture under a dull, patchy layer.

After laser treatment at 1000x, the polyimide surface appears smooth and free of all visible debris now. I've noticed the treatment restores a uniform, glossy finish across every spot. No residues remain to mar the clean, even

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more