FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

Indium phosphide excels in optoelectronic performance, powering laser cleaning tools that precisely strip contaminants while safeguarding delicate substrates.

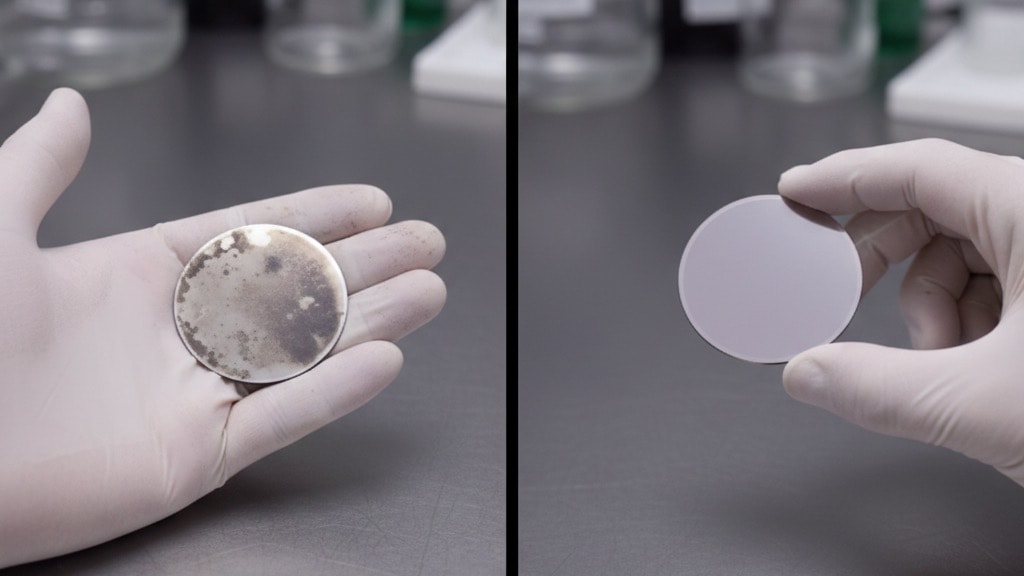

At 1000x magnification, the contaminated surface of Indium Phosphide shows scattered dark spots and uneven layers that cover much of the base material. Fine particles cling tightly to the rough patches, creating a mottled appearance across the entire view. These contaminants obscure the underlying structure and make the surface look dull overall.

After laser treatment, the same surface appears smooth and uniform under 1000x magnification, with no visible particles remaining. The base material now reveals a consistent texture that reflects

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more