ANSI

ANSI Z136.1 - Safe Use of Lasers

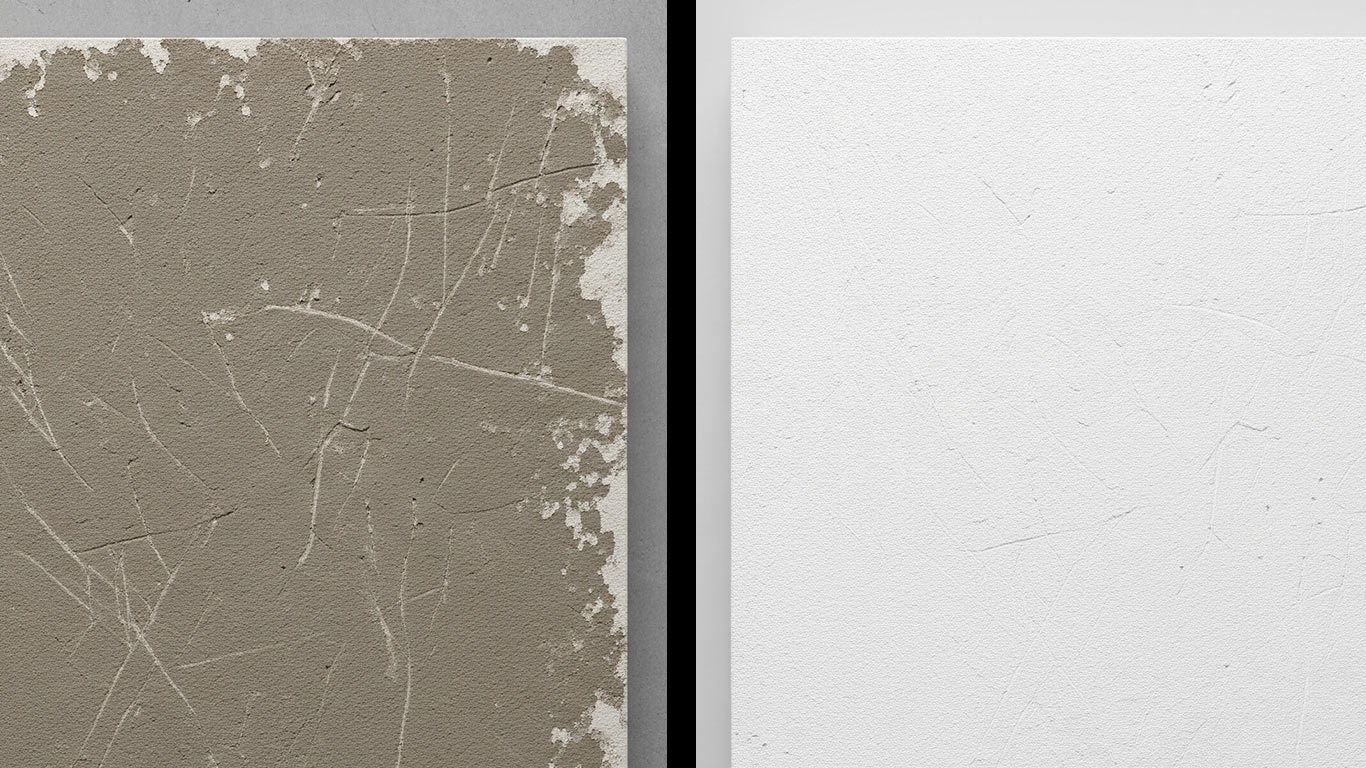

When laser cleaning stucco, mind its breathable surface that clings to grime so deeply, yet this masonry favorite endures steady heat well, letting you safely strip away years of buildup and restore that smooth finish for heritage sites without cracking the base layer.

When examining contaminated stucco at 1000x magnification, you'll see thick layers of dirt and debris clogging every pore and crevice. Grimy particles stick firmly to the rough surface, creating dark spots and uneven buildup that hides the original texture. This mess makes the whole area look dull and blocked, with no clear view of the base material underneath.

After laser treatment at 1000x magnification, you'll notice the surface now appears smooth and open, free from all that clinging gr

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more