FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

When laser cleaning granite surfaces in architectural restoration, we typically adjust the scan speed to match its dense and heat-resistant composition, which exposes underlying details without compromising the stone's structural integrity, so make sure to monitor for any subsurface heating buildup.

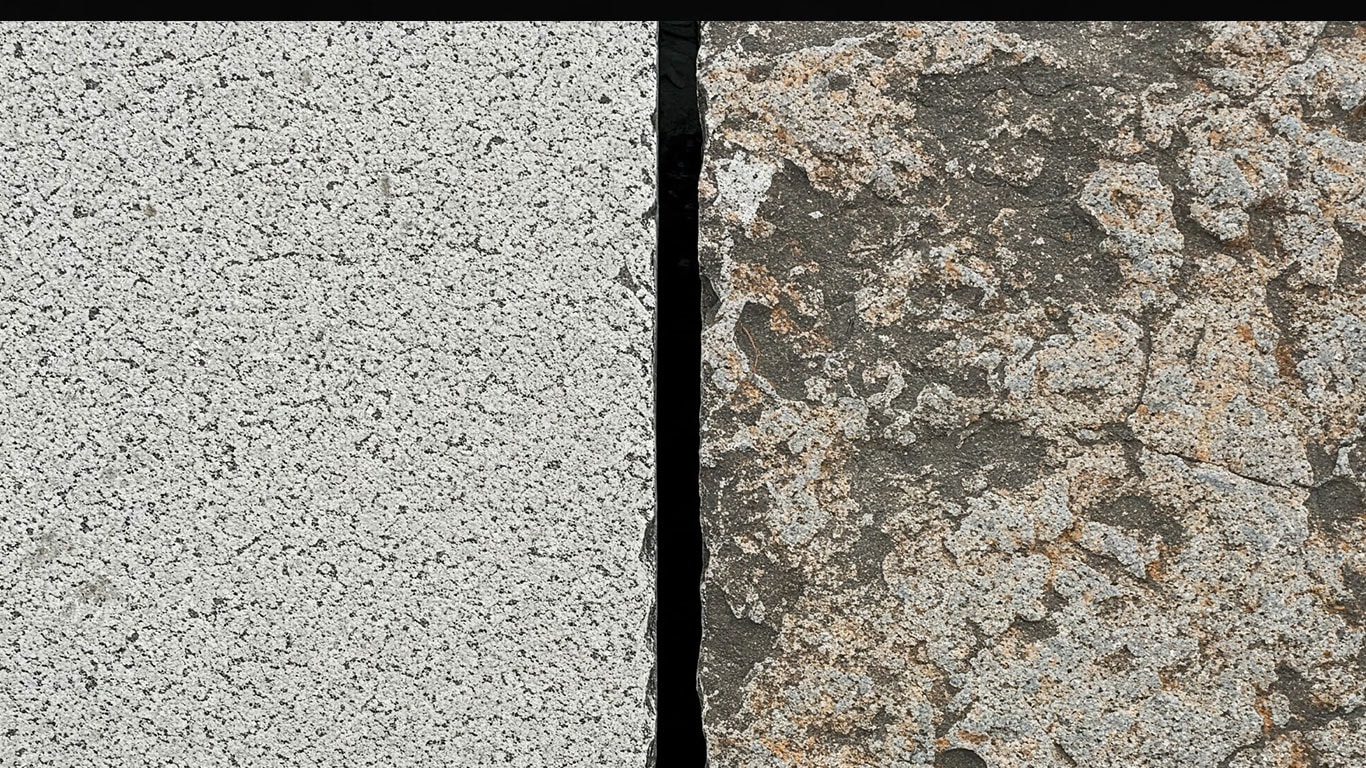

The contaminated granite surface shows dark specks clinging tightly to rough patches. Fine dust layers cover the mineral grains, hiding their natural edges. Pores fill with gritty residues, making the texture uneven and dull.

Laser treatment removes the dark specks, exposing clear mineral grains. Smooth patches emerge where dust once hid the edges. Clean pores reveal a sharper texture, bright and even overall.

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment

EPA Clean Air Act Compliance

ASTM C615 - Standard Specification for Granite Dimension Stone