ANSI

ANSI Z136.1 - Safe Use of Lasers

We've found that thermoplastic elastomer responds well to laser cleaning, thanks to its rubber-like flexibility paired with plastic processability, allowing precise surface restoration without compromising structural integrity.

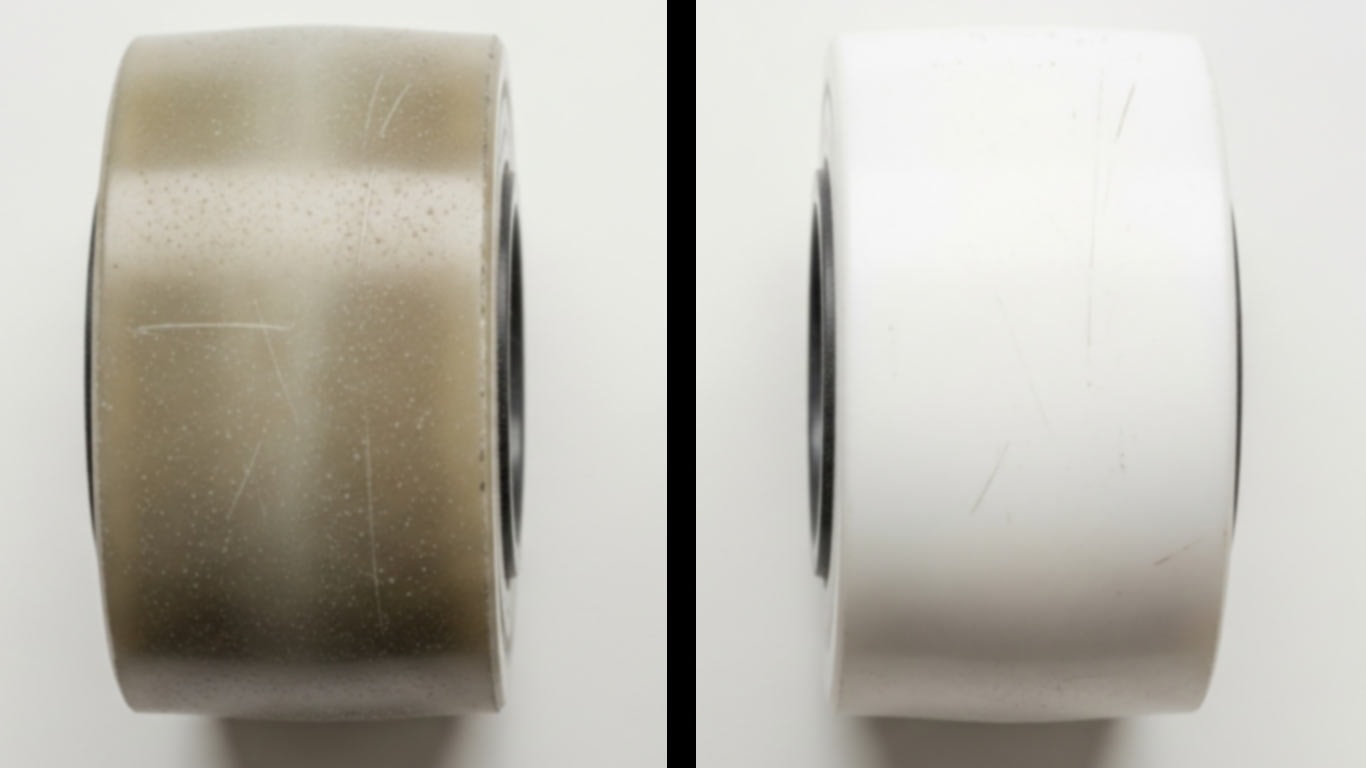

The contaminated surface appears rough and dotted with dark specks. Clumps of debris cling tightly to the uneven texture. Fine particles scatter across the material, hiding its natural form.

Laser treatment reveals a smooth and uniform layer underneath. The surface now looks clear and even, free from any clinging residues. Clean ridges emerge, showing the material's true structure.

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more