ANSI

ANSI Z136.1 - Safe Use of Lasers

When laser cleaning tempered glass, ensure you utilize its excellent thermal shock resistance to remove contaminants safely, without risking fractures.

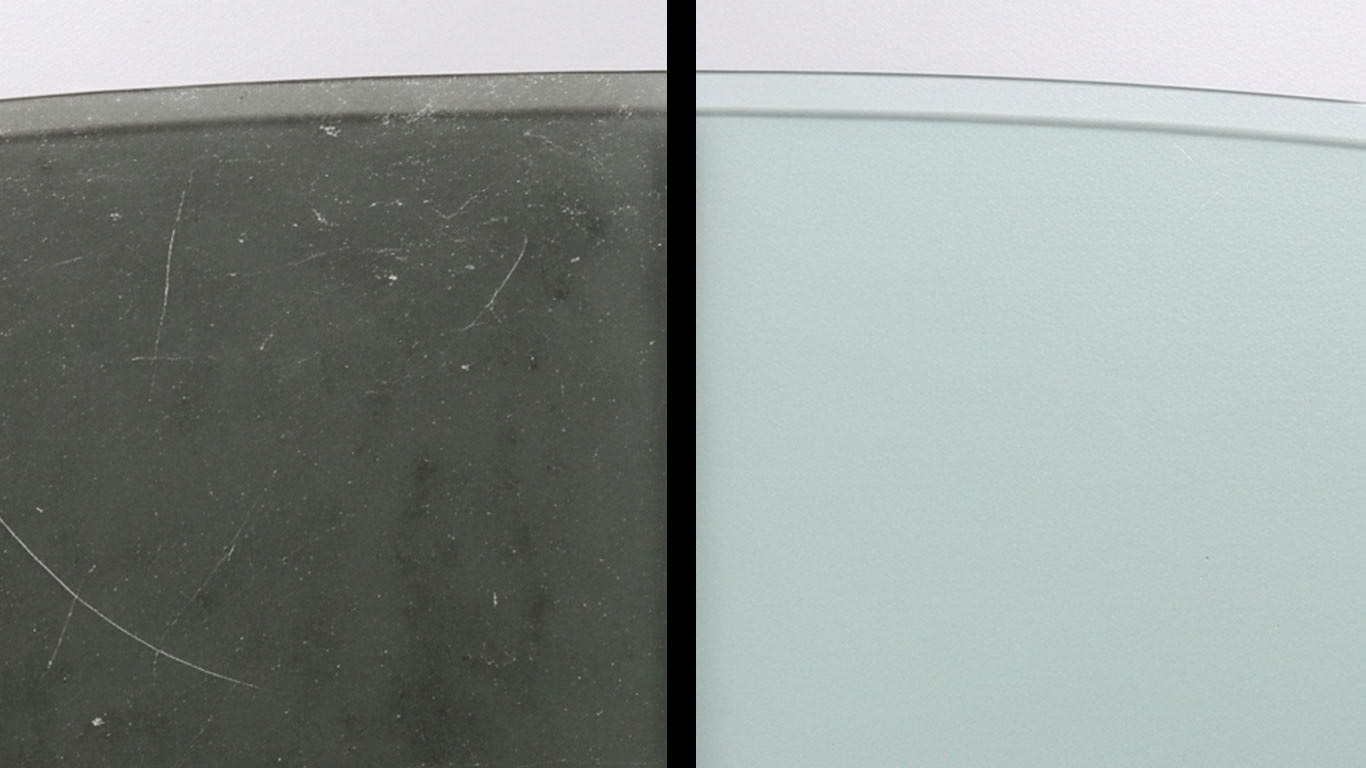

When examining the contaminated tempered glass surface at high magnification, we've found irregular patches of dirt and residue clinging tightly. These spots create a rough, uneven texture that scatters light in all directions. You can see tiny cracks and buildup everywhere, making the whole area look dull and hazy.

After laser treatment, the same surface appears smooth and uniform across the view. We've noticed the glass now reflects light cleanly without any distractions. The finish looks pristine, with no traces of those old contaminants left behind

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more