FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

In contrast to other rare-earth elements that exhibit broader emission spectra, Europium delivers a sharp red luminescence that improves color purity in optical components and electronics, supporting precise cleaning processes that restore fluorescence without compromising surface integrity

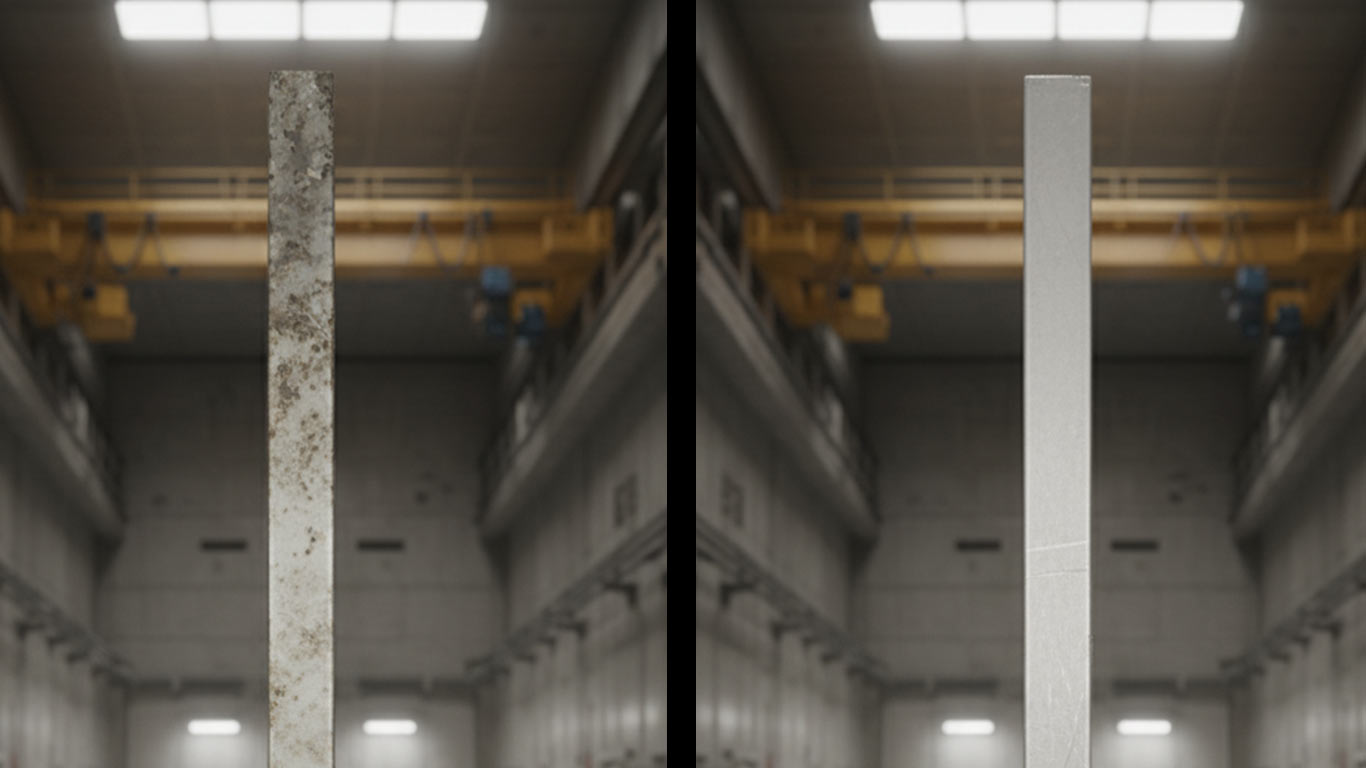

The contaminated surface displays a mottled layer of dark residue and scattered debris across its uneven texture. Rough patches and clinging particles obscure the base material beneath this dull coating. Tiny irregularities dot the view, giving it a worn and irregular appearance.

The clean surface reveals a smooth and uniform expanse free from any residue or debris. Polished facets reflect light evenly over the entire area now. The base material exposes its inherent luster and flawless contours clearly.

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more