ANSI

ANSI Z136.1 - Safe Use of Lasers

In our work with terbium for laser cleaning, we've noticed it stands out from other rare-earth metals by bouncing back most of the laser energy, which means cleaner surfaces on aerospace parts with no worry of deep material damage.

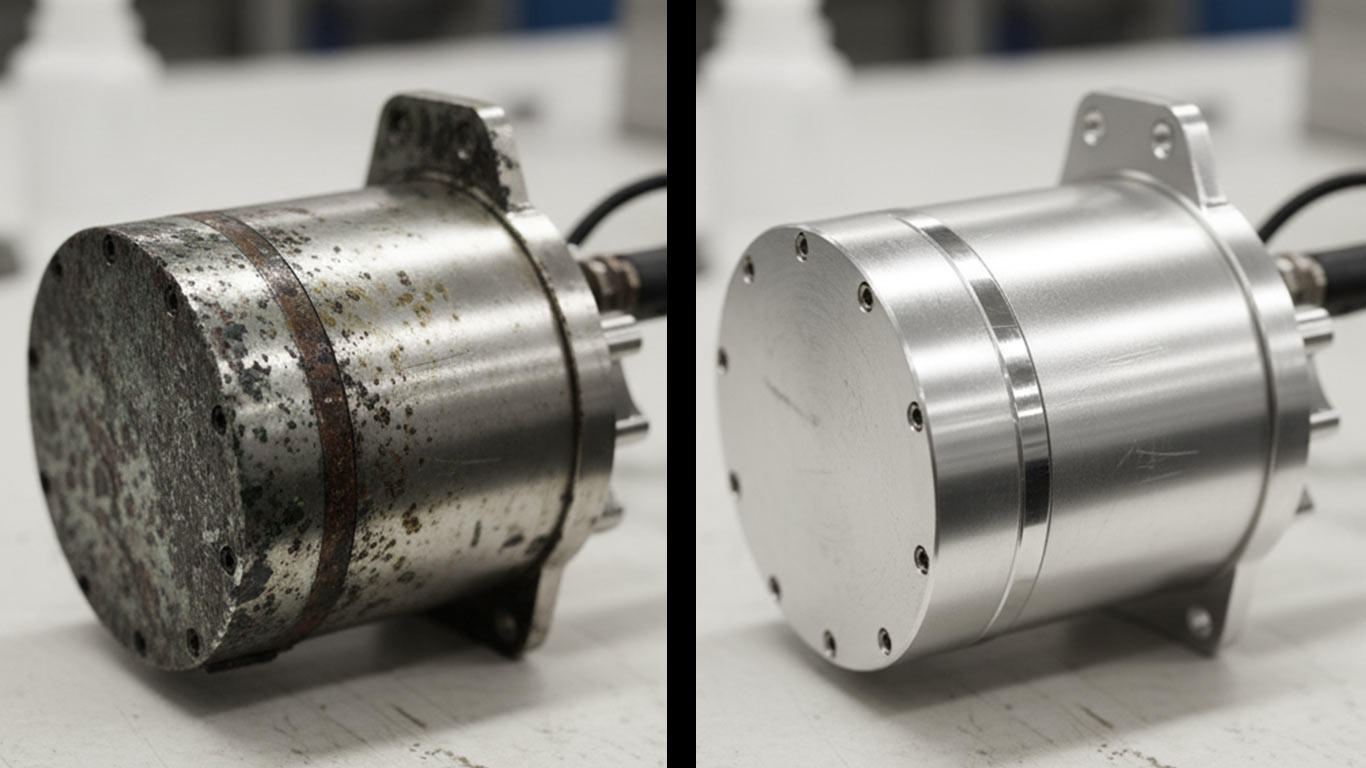

We've found that before laser cleaning, the Terbium surface at 1000x shows a jagged, pitted landscape dotted with dark specks of grime and debris that obscure the underlying metal grains. These contaminants form irregular clumps, making the whole area look dull and uneven under close inspection. In our experience, this buildup often traps fine particles deep in the crevices, complicating any surface analysis right away.

After the laser treatment, though, the same Terbium view at 100

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more