FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

In my experience, Carbon Fiber Reinforced Polymer works wonders in aerospace and automotive designs by combining incredible tensile strength with remarkably low weight compared to traditional metals, enabling lighter structures that perform better—though you should avoid sharp impacts to prevent fiber breakage.

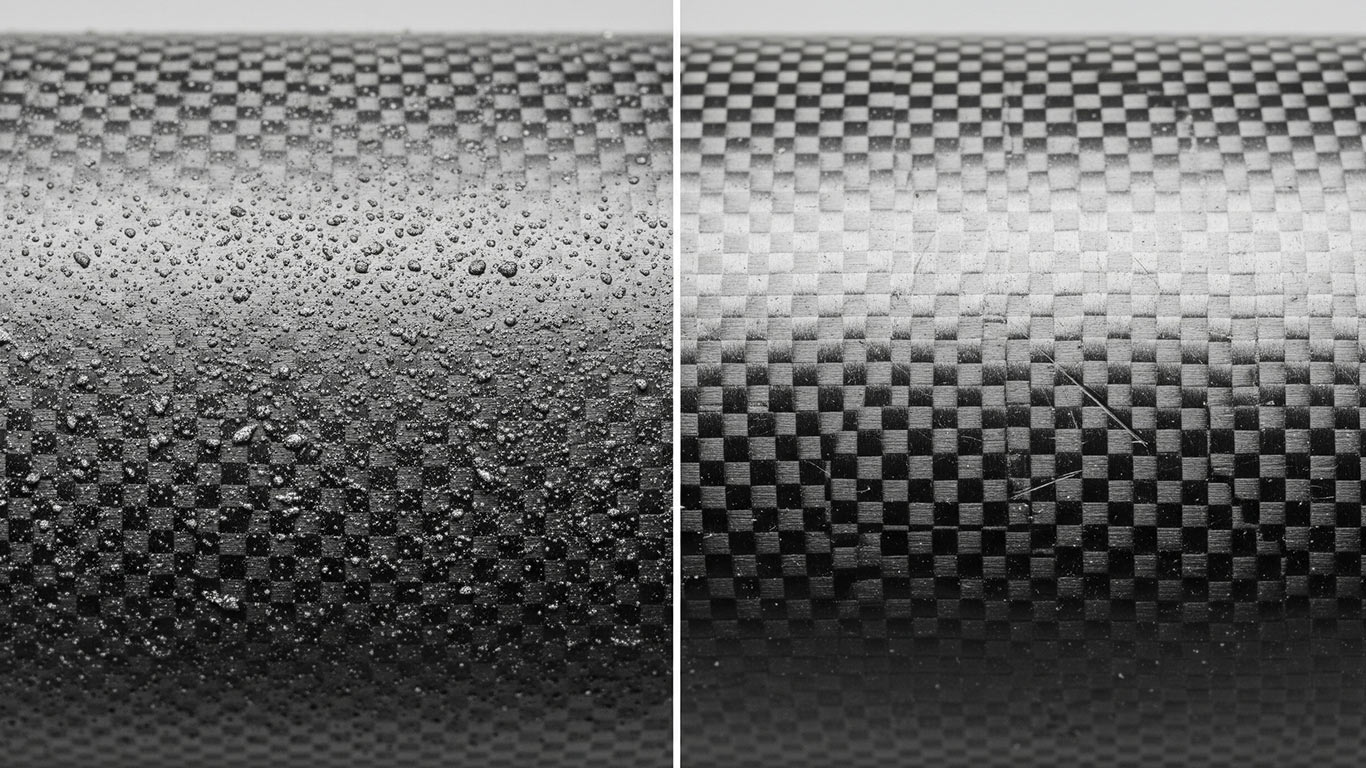

We've found the contaminated surface shows fibers matted with dark residues. Dirt clings tightly to the matrix, hiding the weave below. Scattered particles block the smooth flow of strands.

After treatment, the laser reveals crisp fibers standing out clearly. The matrix gleams evenly without any leftover grime. Strands now connect smoothly across the whole area.

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more