FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

When working with Ceramic Matrix Composites in high-heat environments, prioritize their superior toughness that resists cracking under thermal stress, allowing them to surpass brittle traditional ceramics by preserving structural integrity in aerospace or energy applications

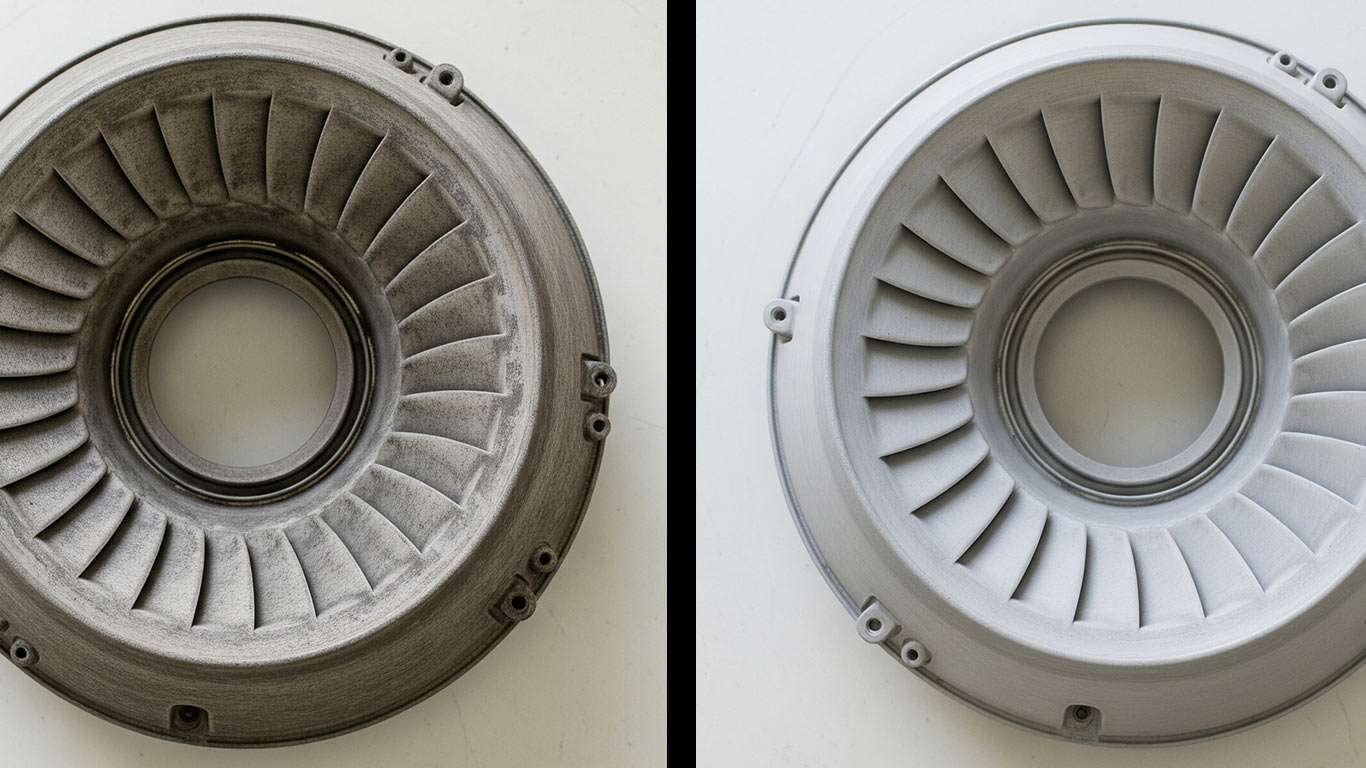

I've seen contaminated CMC surfaces under magnification show a rough, dusty layer everywhere. Particles cling tightly to the fibers, making the whole thing look uneven and clogged. This buildup hides the material's true texture completely.

After laser treatment, the same surface appears smooth and open. Fibers stand out clearly now, free from any clinging debris. The clean look reveals a uniform, fresh structure overall.

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more