FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

Compared to denser granites, limestone's porous structure absorbs contaminants more readily during laser cleaning and resists cracking from heat buildup, so you'll preserve surface details without aggressive passes.

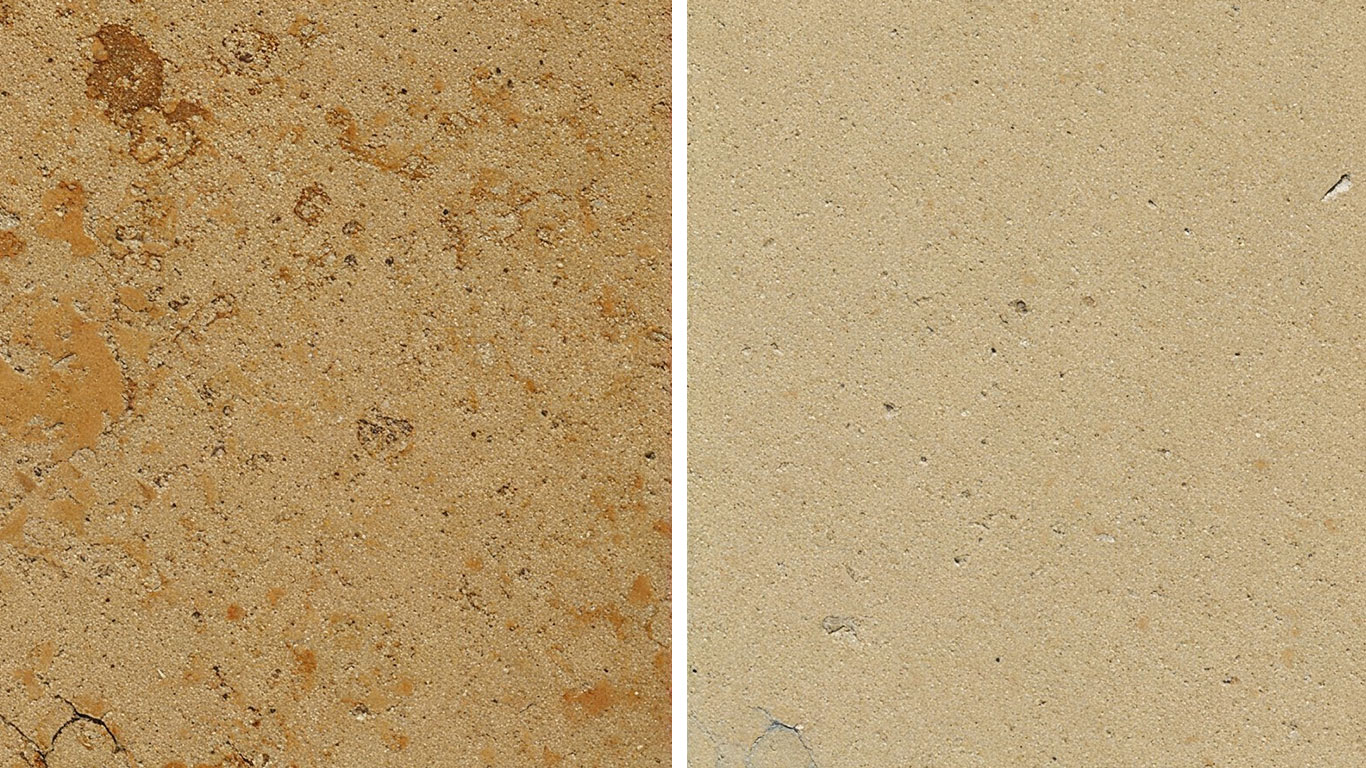

I've seen limestone surfaces like this before cleaning, where grime covers everything in a dull layer. Dark specks and uneven bumps scatter across the texture, making it feel heavy and obscured. The whole area appears choked with fine debris that hides the natural grain.

After the laser treatment, that same surface shines with a fresh, even glow. Smooth patches emerge where the dirt once stuck, revealing clean edges and subtle patterns. Now it looks open and vibrant, free from those clinging residues.

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment

EPA Clean Air Act Compliance

ASTM C568 - Standard Specification for Limestone Dimension Stone