FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

Unlike fragile marbles that splinter easily under laser beams, onyx withstands intense heat without cracking due to its solid density, allowing restorers to safely revive cultural artifacts.

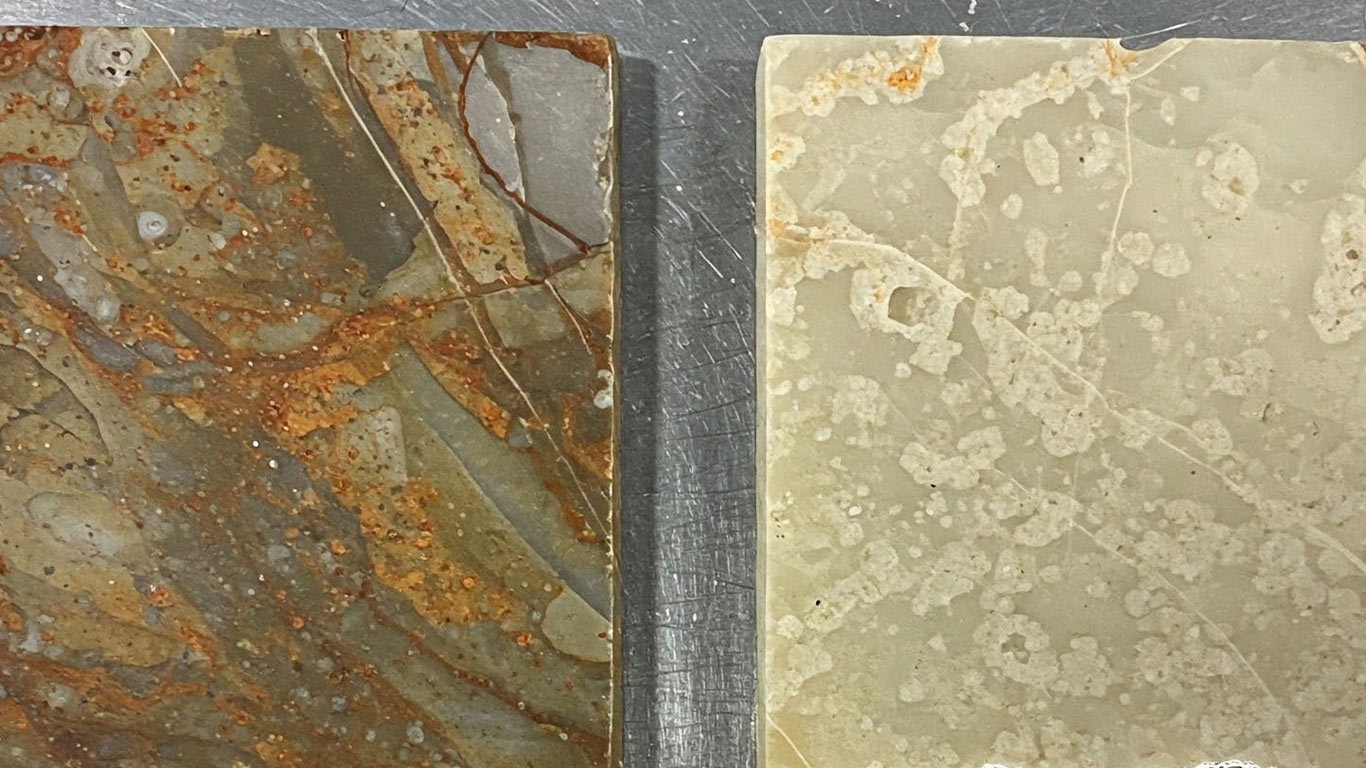

You see the onyx surface covered in a thick layer of grime and dust particles. Tiny specks cling tightly to every crevice and rough spot. The whole thing looks dull and uneven under this close view.

The laser treatment wipes away all that buildup completely. Now the surface shines smooth and reveals fine natural bands. It appears fresh and uniform across the entire area.

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more