FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

We've found that Gallium stands out among metals due to its low melting point near room temperature, enabling fluid handling in semiconductor manufacturing while requiring careful thermal control to avoid deformation

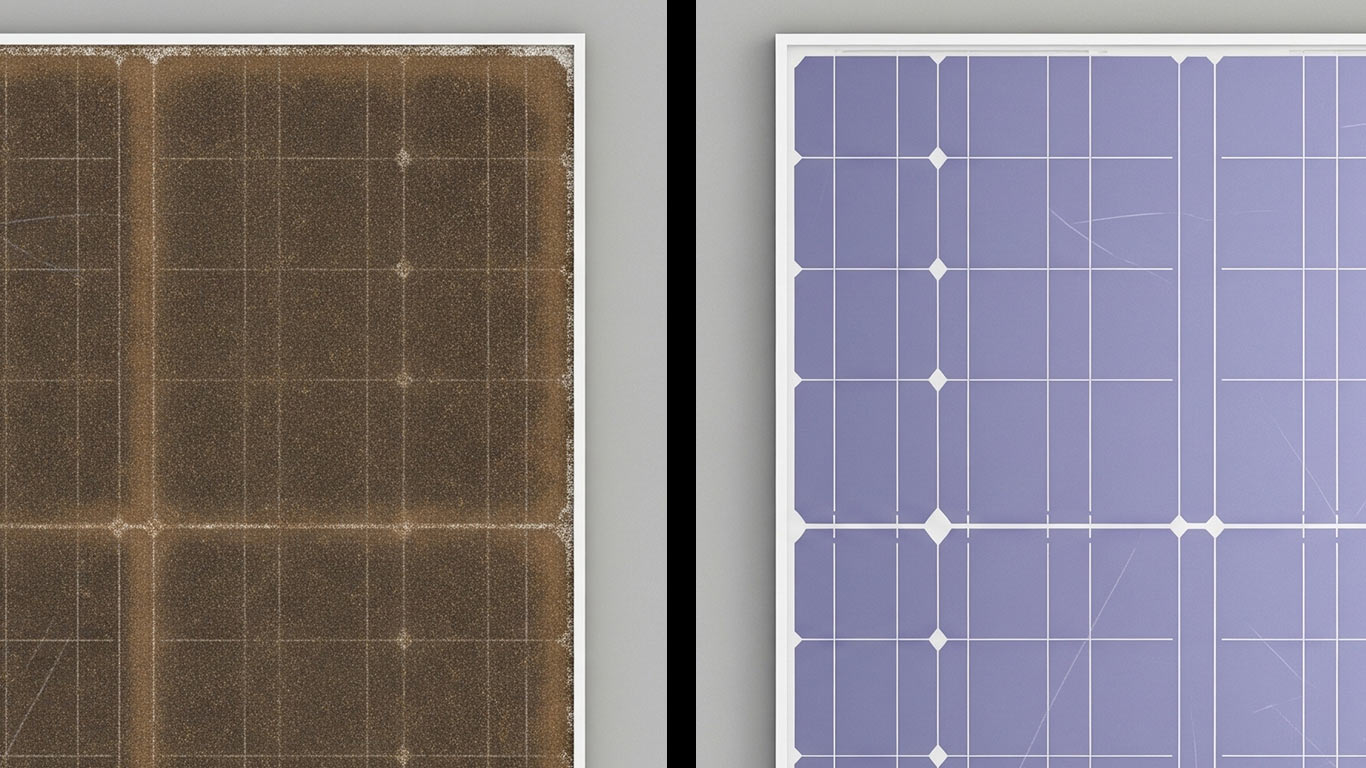

When examining the contaminated Gallium surface at 1000x magnification, you notice scattered dark spots and uneven patches across the material. These irregularities make the surface look rough and dull under close inspection. Contaminants cling tightly, obscuring the underlying texture completely.

After laser treatment, the same surface appears smooth and uniform at 1000x magnification. The process removes all visible residues, revealing a consistent metallic sheen. This cleaning restores clarity, exposing the material's natural, even finish without

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more