FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

Polytetrafluoroethylene exhibits strong chemical resistance and low friction. For laser cleaning, it allows precise contaminant removal without residue, thus preserves surface integrity in demanding fields like aerospace and medical devices. Thermal sensitivity poses challenges, so controlled processing follows to avoid deformation.

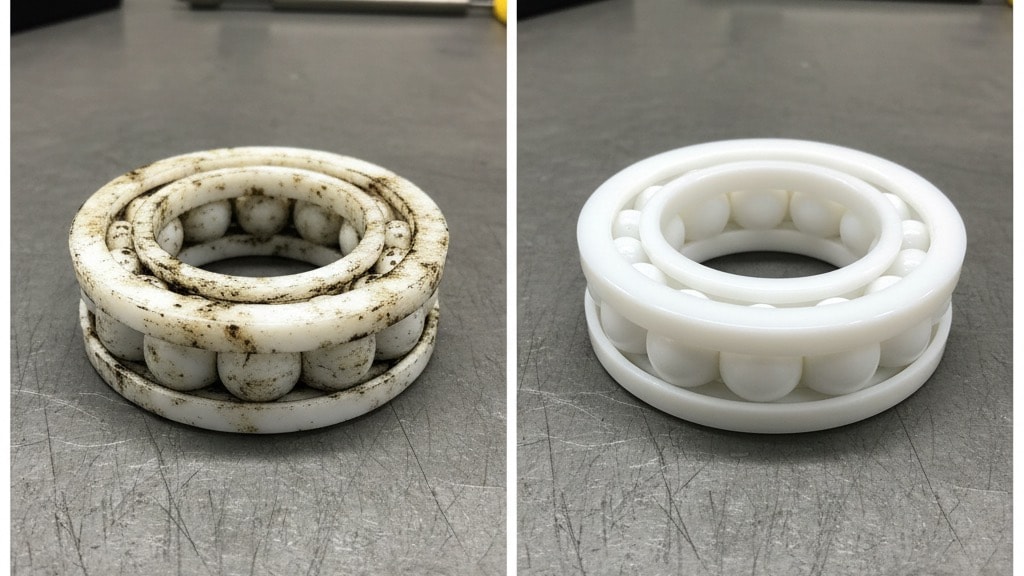

At 1000x magnification, the contaminated surface bristles with jagged debris and sticky residues.

Dark smudges cluster in pockets, dulling the overall texture.

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more