FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

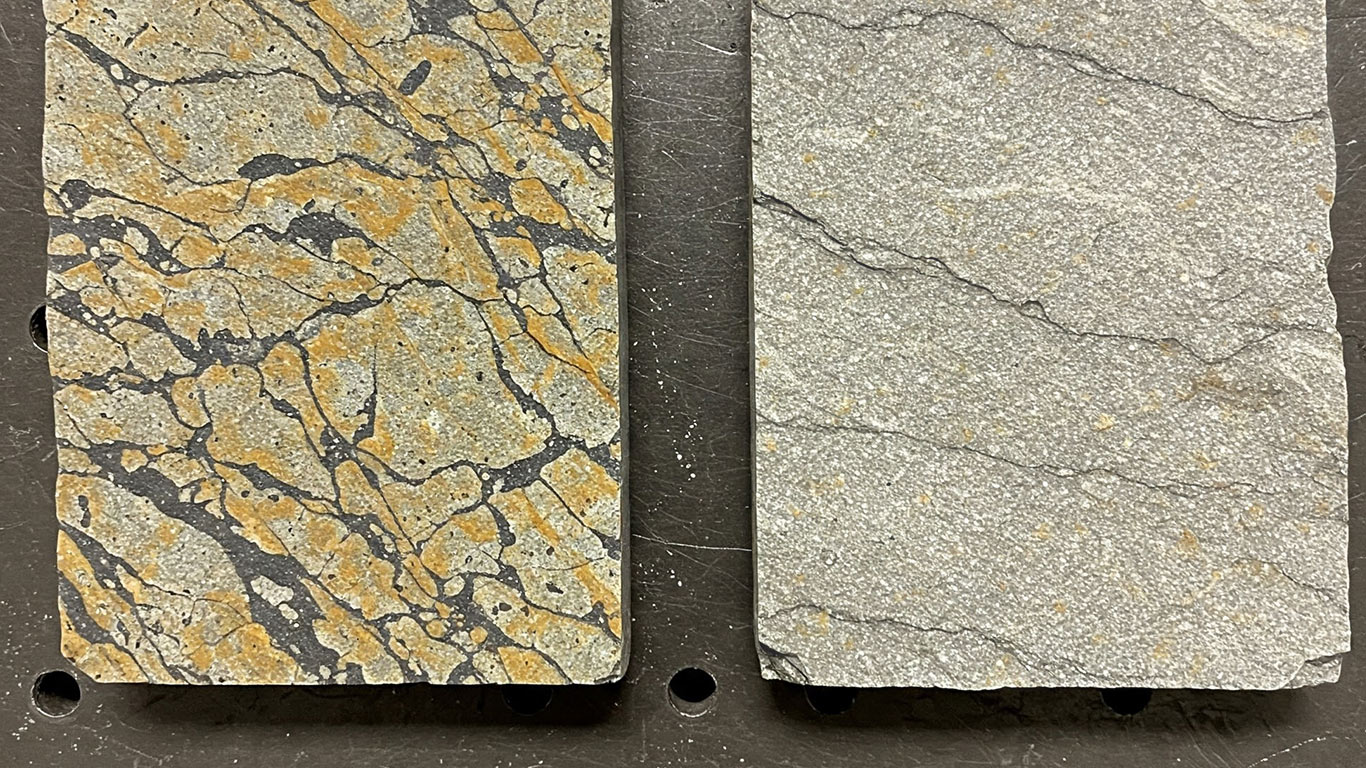

Schist's defining feature is its foliated layers, which distinguish it from more uniform stones and let us restore heritage surfaces via laser cleaning, all while keeping the underlying textures intact without any risk of cracking.

The contaminated surface reveals clusters of dark particles scattered across uneven layers. Fine debris clings tightly, obscuring the underlying flaky patterns. Grimy films dull the natural sheen in visible spots.

Laser treatment exposes smooth, layered structures with clear mineral flecks. Clean planes highlight the rock's inherent alignment and texture. Restored surfaces show vibrant contrasts without residual buildup.

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment