FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

The key to Indium is its remarkably low melting point, which sets it apart from tougher metals by enabling soft, reliable seals in electronics and aerospace components. We've found it perfect for delicate soldering tasks where high heat could ruin sensitive parts, but always keep processing temperatures gentle to maintain its integrity.

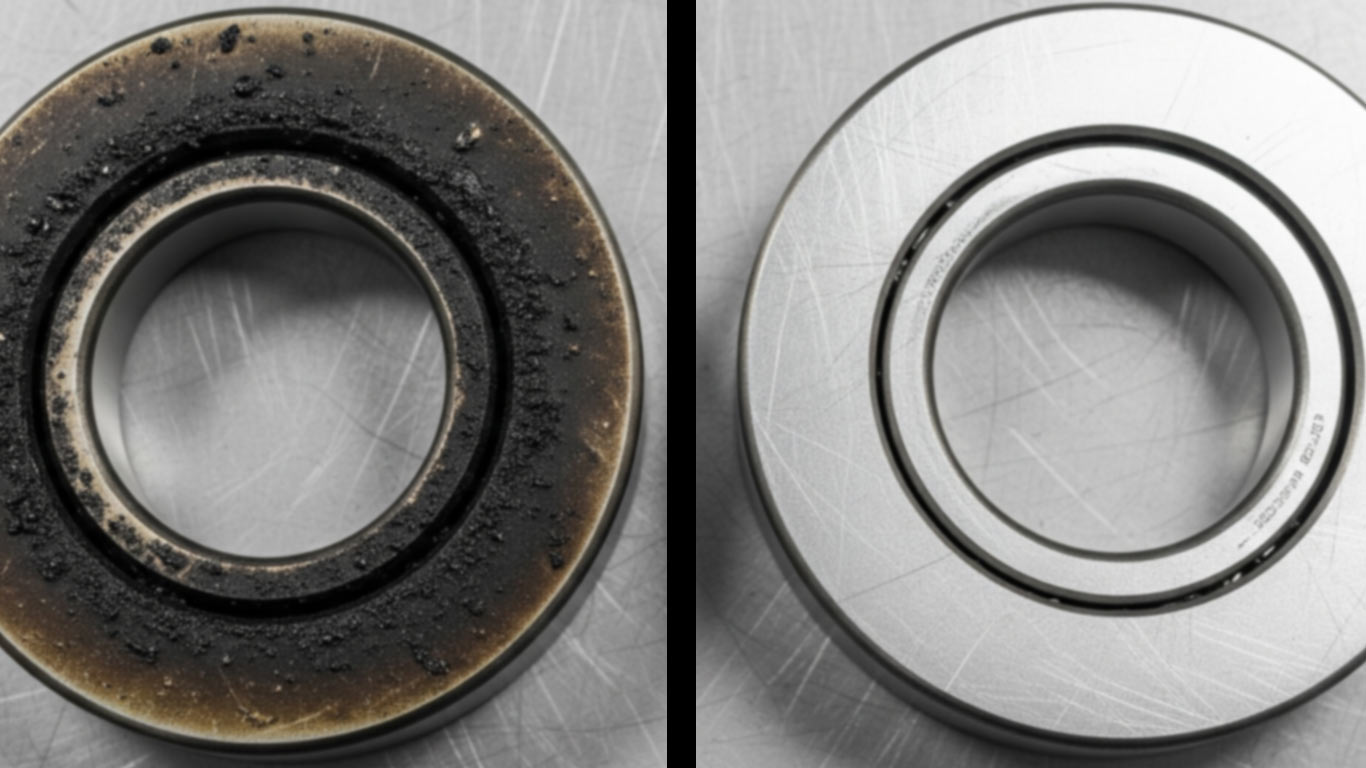

We've noticed the indium surface looks rough and dotted with dark spots before cleaning. Grimy layers cling tightly, making the metal seem dull and uneven under magnification. This buildup hides the underlying shine, complicating any close inspection.

After treatment, the surface appears smooth and reflective across the view. Clear areas reveal a consistent metallic gleam without those stubborn residues. Now, the material shows its true, pristine texture ready for use.

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment