FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

When laser cleaning manganese, you'll want to kick off with moderate power levels and steady scan speeds to make the most of its low thermal conductivity, which keeps heat nicely localized but calls for close monitoring along the way to avoid uneven oxidation on any delicate parts.

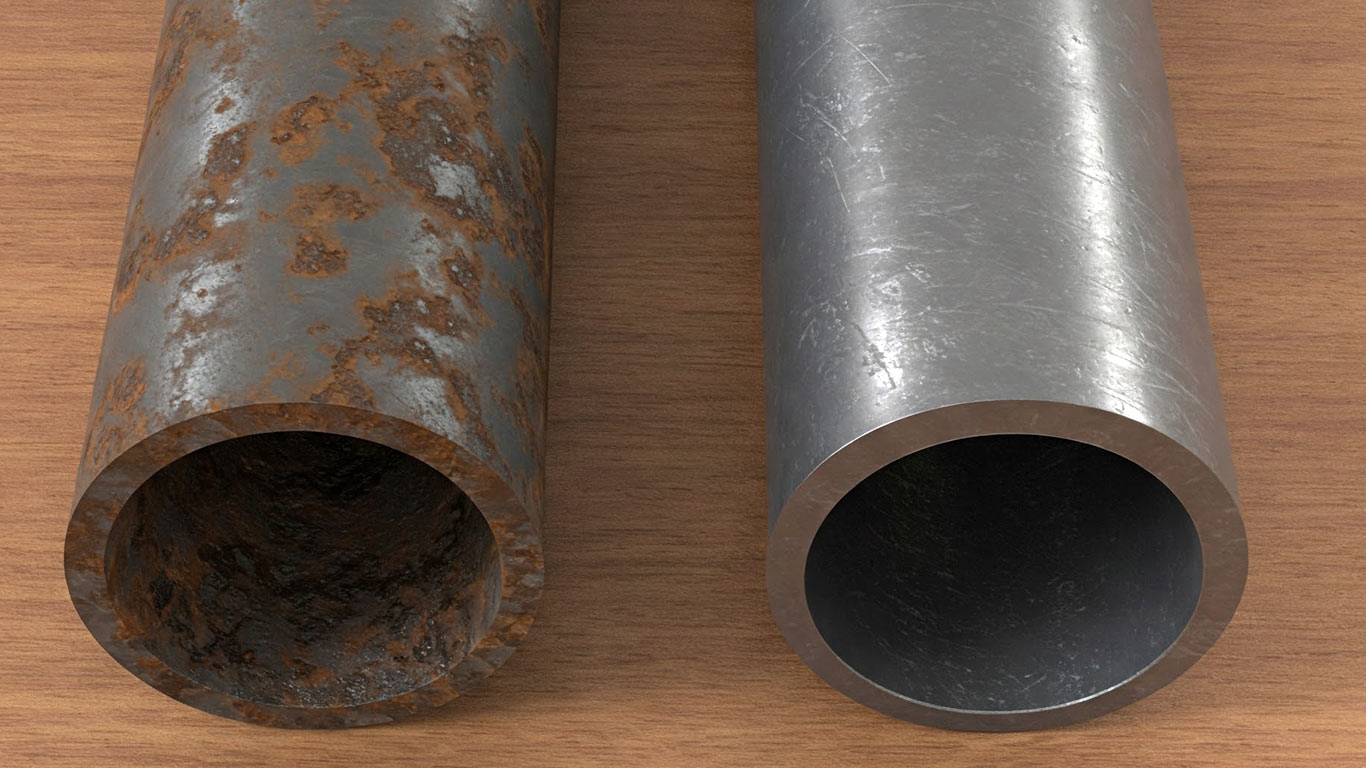

The contaminated manganese surface appears rough and uneven under magnification. Layers of dark residue cling tightly to the metal, hiding its natural texture. Pits and scratches scatter across the view, making the whole area look dull and worn.

Laser treatment restores the manganese surface to a smooth, even finish. The clean metal now shines brightly without any clinging debris. Fine details of the grain structure emerge clearly, revealing a uniform and polished appearance.

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment