FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

We've found hafnium distinguishes itself from other non-ferrous metals through its exceptional resistance to extreme heat, allowing sustained integrity in demanding aerospace and nuclear environments without deformation, so monitor exposure to oxidizing conditions to preserve its protective oxide layer

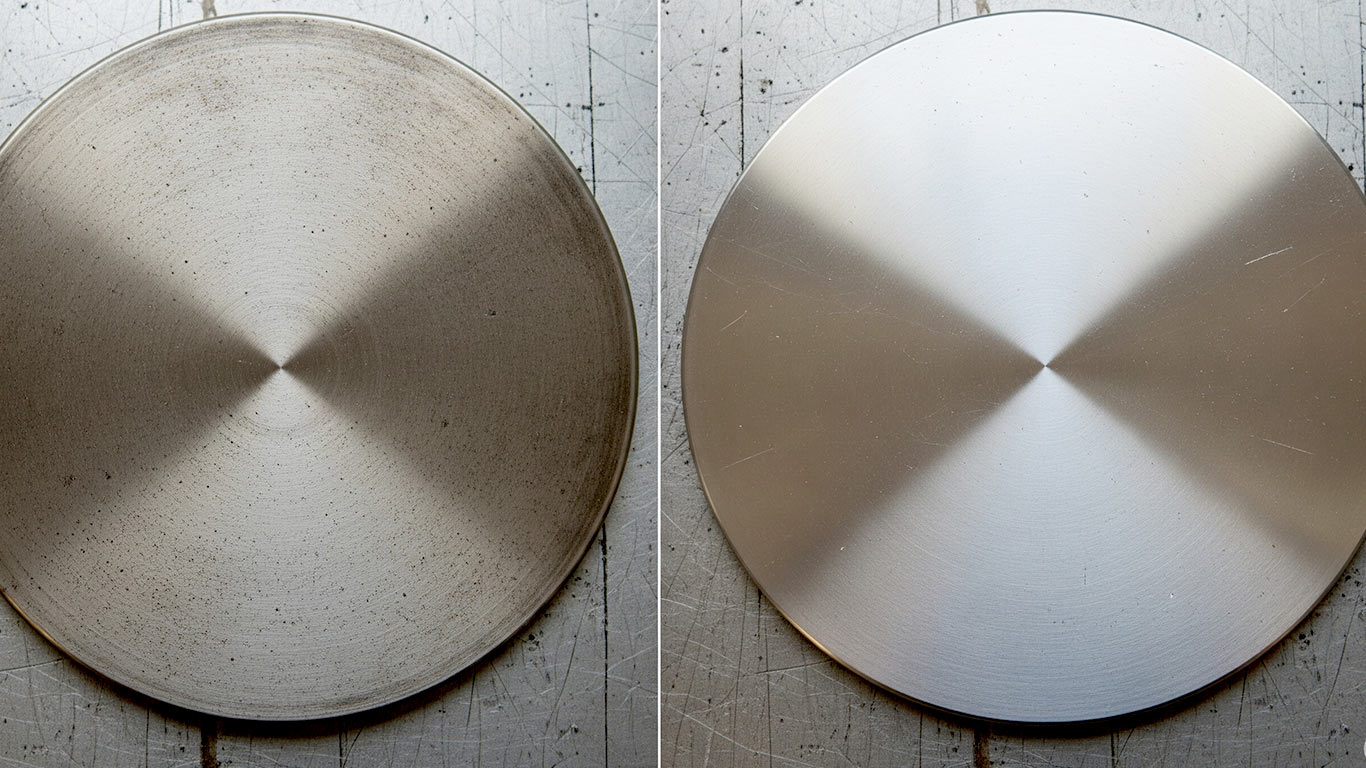

The contaminated hafnium surface appears uneven and dotted with dark residues. Clumps of debris stick firmly across the rough texture. Layers of grime hide the underlying metal structure.

Laser treatment restores the hafnium surface to a smooth, even finish. It removes all visible contaminants without leaving marks. The clean metal now reveals a uniform, reflective appearance.

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more