FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

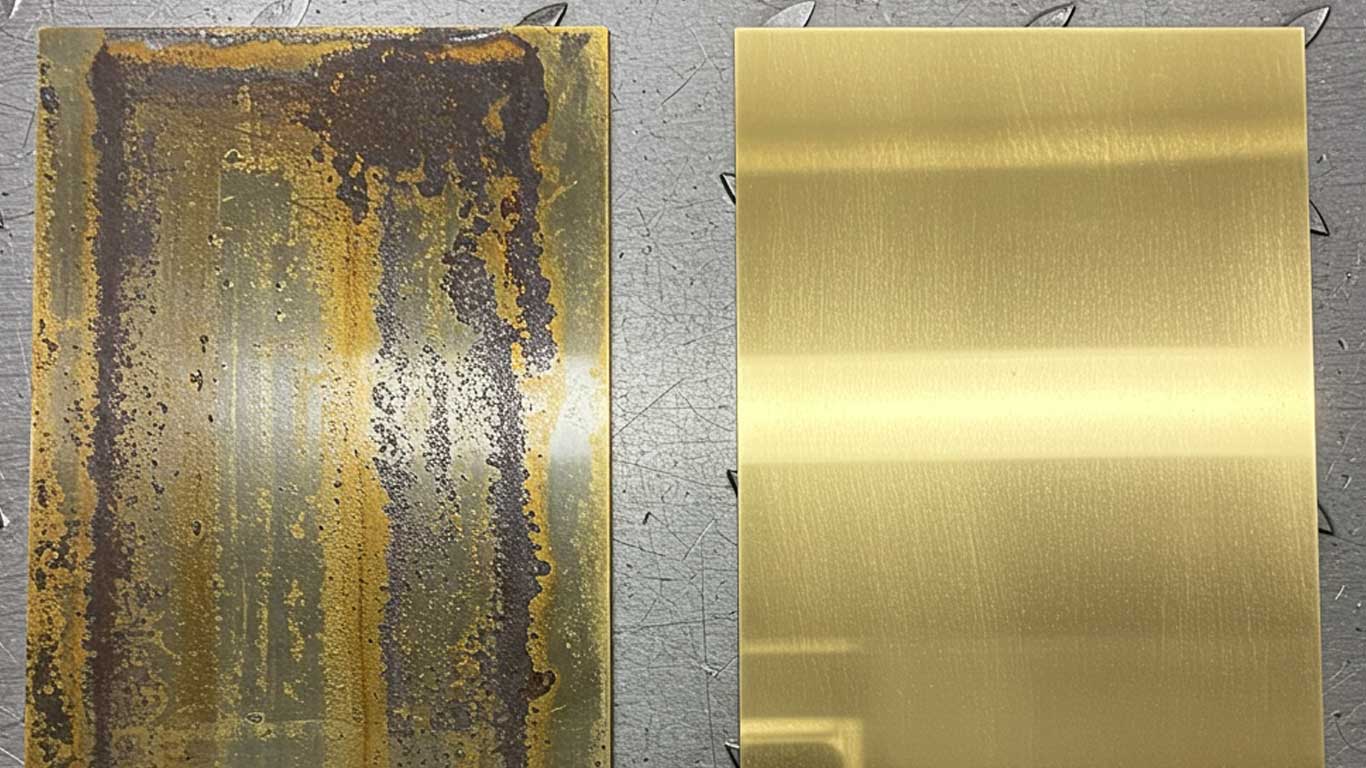

Brass, as non-ferrous metal, shows high reflectivity during laser cleaning, so treatment removes surface oxidation and contamination from marine or plumbing uses without deep substrate damage. Because of its good corrosion resistance and thermal shock tolerance, process restores uniformity on surfaces effectively, and this sets brass apart from ferrous alternatives that suffer more from heat buildup.

Under the microscope at high magnification, the brass surface looks clogged with thick, uneven layers of dirt and oxidation. Dark smears and tiny debris spots disrupt the metal's natural sheen everywhere. Pits and scratches hide beneath this buildup, making the texture feel rough and dull.

After laser treatment, the same view reveals a smooth, even surface free of all contamination. Bright, reflective areas now dominate, with no traces of grime or spots left behind. The texture appears polished and uniform, restoring

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more