ANSI

ANSI Z136.1 - Safe Use of Lasers

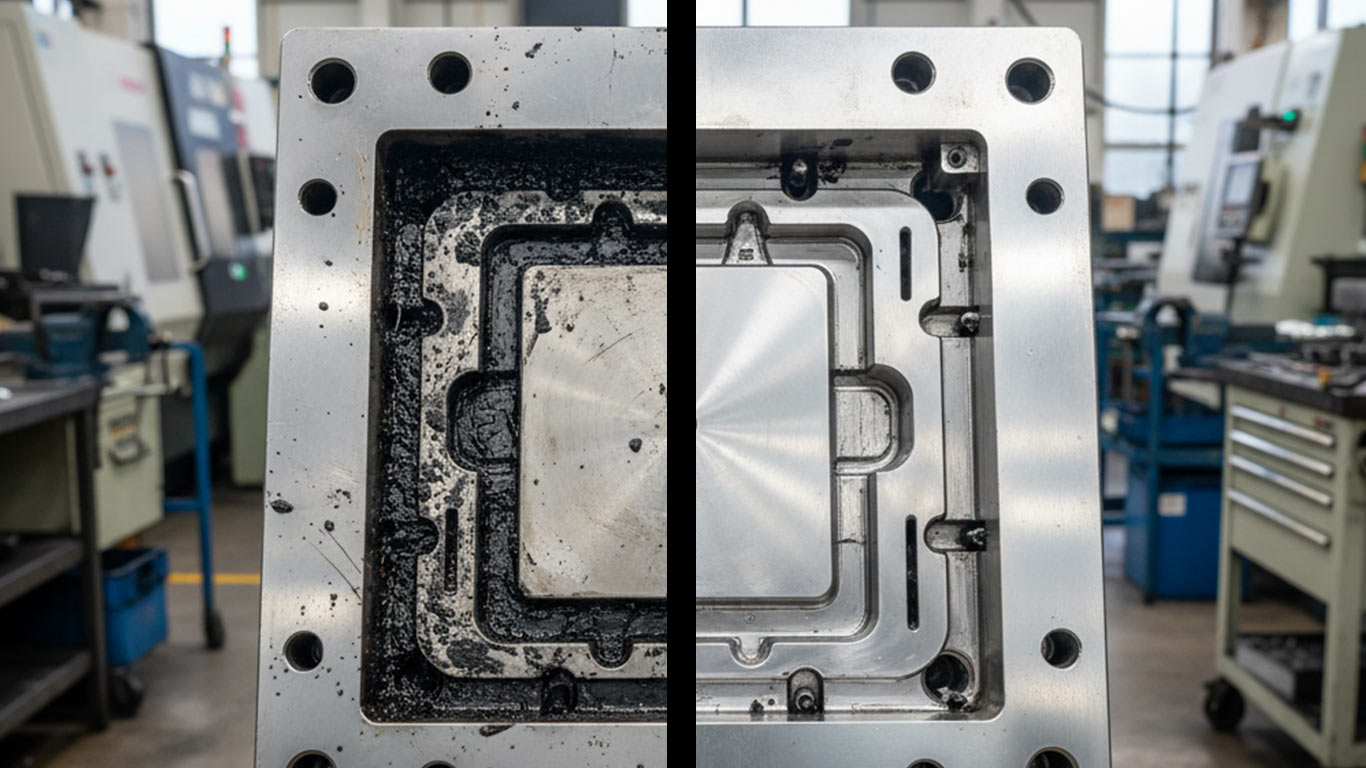

When laser cleaning Tungsten Carbide, consider its dense nature right away—it holds heat longer than lighter ceramics, so ease in slowly to prevent any buildup. I've found this approach works well with steady passes that remove stubborn residues from mining tools without marring the hard surface. What makes it stand out is that relentless toughness, which lets parts stay whole for reuse in tough environments like oil rigs or dies.

When you examine the contaminated tungsten carbide surface at 1000x, rough patches of grime cling tightly to every crevice. Dark residues build up in layers, hiding the material's true texture beneath a dull haze. Scattered debris dots the view, making the whole area look uneven and worn.

After laser treatment, the same surface appears smooth and uniform across the field. The clean finish reveals a consistent shine without any lingering spots. Now, the material's natural polish stands out clearly

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more