Diamond-Like Carbon Removal

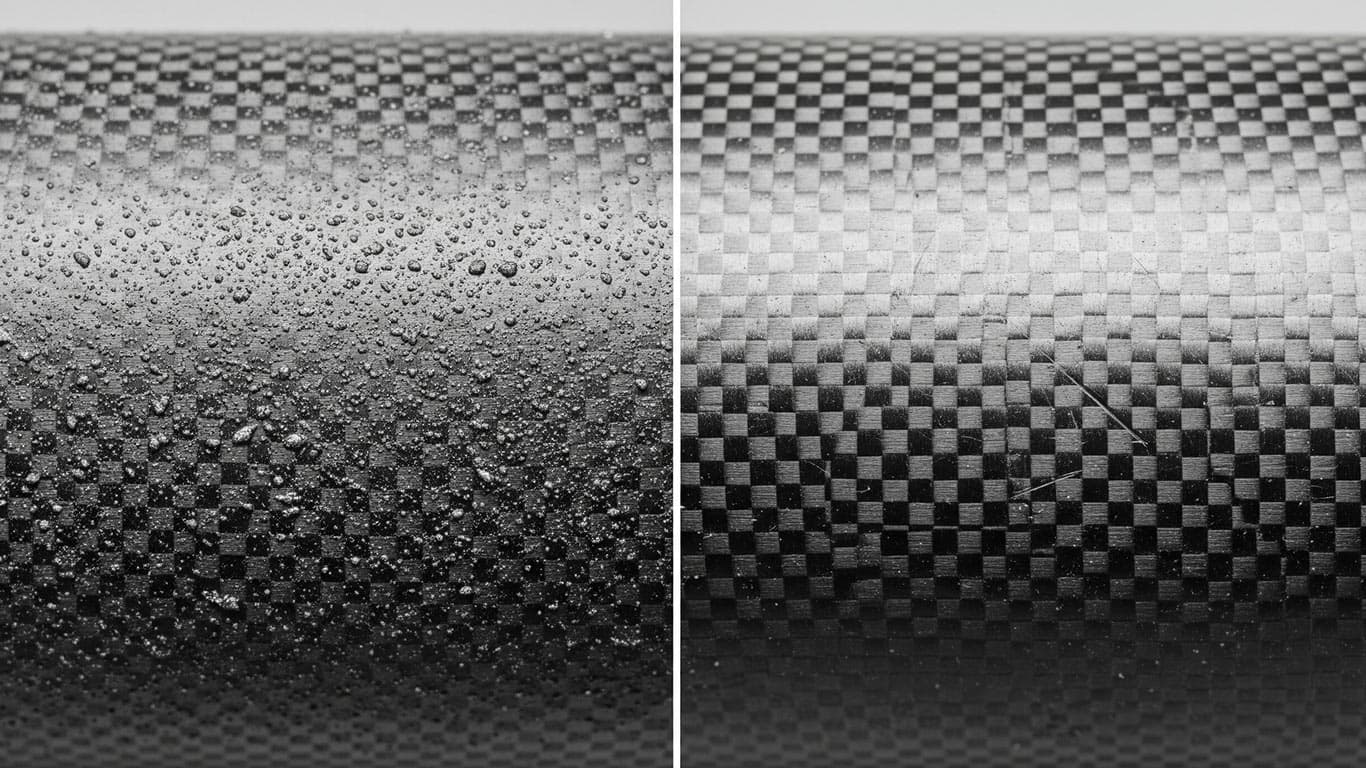

Diamond-coating contamination poses removal challenges in laser cleaning. Contaminants form unique patterns on diamond surfaces because heat resistance causes uneven buildup during exposure. Layer adheres strongly, so laser pulses struggle to detach it without damaging coating. After initial cleaning, residue persists on edges. Process targets inorganic layers effectively, yet material hardness demands precise control. Contamination exhibits dense attachment, and removal requires adjusted wavelengths for safety. In observations, patterns vary by substrate, so intervals prevent overheating. Buildup is detected early on polished areas. Treatment removes layers gradually, and surface regains uniformity afterward.

Ikmanda Roswati, Ph.D.

Indonesia

Produced Compounds

Affected Materials

Aluminum

Brass

Brick

Bronze

Carbon Fiber Reinforced Polymer

Cast Iron

Ceramic Matrix Composites CMCs

Concrete

Copper

Epoxy Resin Composites

Fiberglass

Granite

Iron

Limestone

Magnesium

Marble

Metal Matrix Composites MMCs

Nickel

Phenolic Resin Composites

Polyester Resin Composites

Porcelain

Sandstone

Slate

Stainless Steel

Steel

Terracotta

Titanium

Titanium Carbide

Tool Steel

Urethane Composites

Zinc

Titanium Alloy (Ti-6Al-4V)

Stainless Steel 316

Stainless Steel 304

Aluminum Bronze

Aluminum Nitride

Titanium Nitride

Diamond-Like Carbon Removal Dataset

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more