ANSI

ANSI Z136.1 - Safe Use of Lasers

When laser cleaning Titanium Carbide components, we typically begin by precisely calibrating the setup to accommodate its remarkable heat resistance and low thermal expansion, ensuring no warping occurs during the process and allowing us to remove contaminants from aerospace or manufacturing tools effectively, all without affecting the material's celebrated hardness and durability.

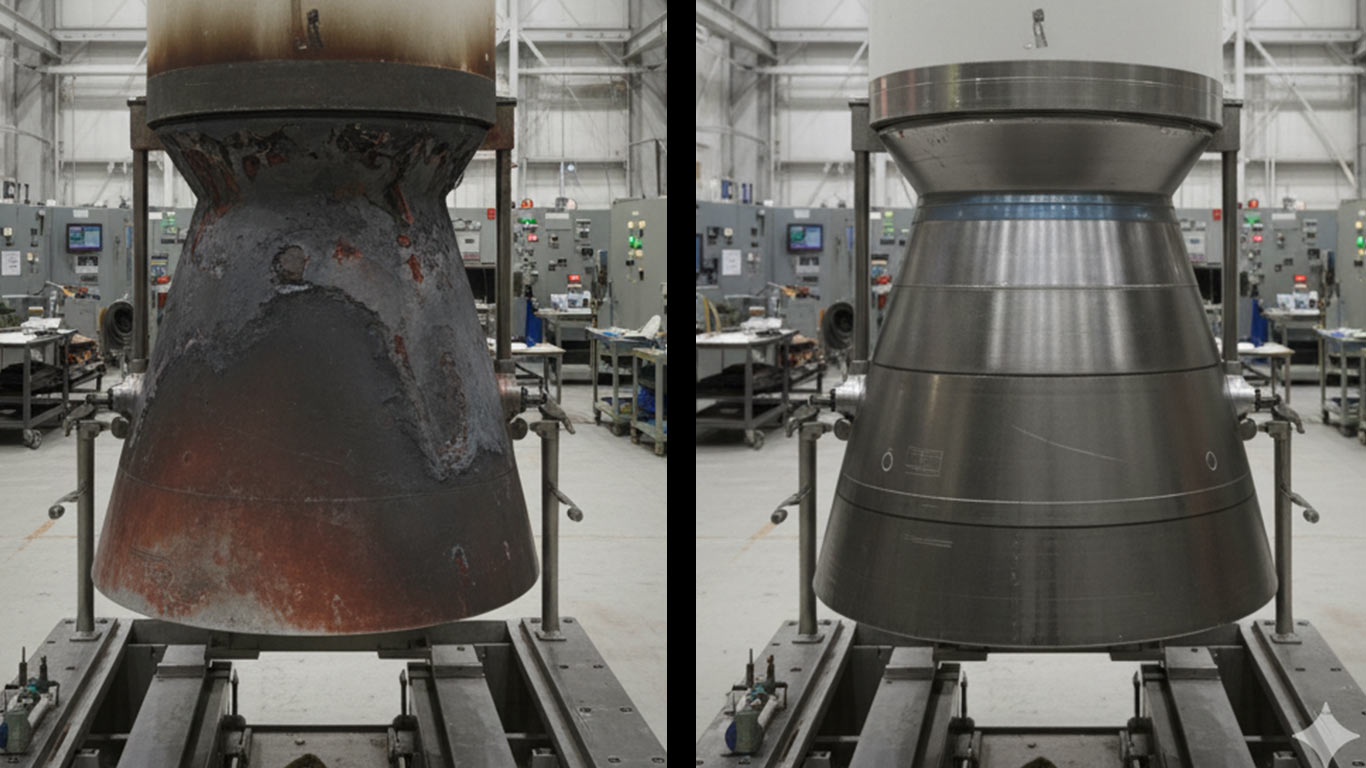

We've found that the contaminated titanium carbide surface at high magnification reveals stubborn layers of grime and particles scattered across it. Dark spots and irregular patches dominate the view, making the underlying material hard to discern amid the buildup. This cluttered appearance suggests years of exposure to harsh environments.

After laser treatment, we've observed how the same surface transforms into a clear and even expanse. Smooth facets emerge without any residue, allowing the material's natural sheen to shine through consistently. The cleaned view now highlights a uniform

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more