FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

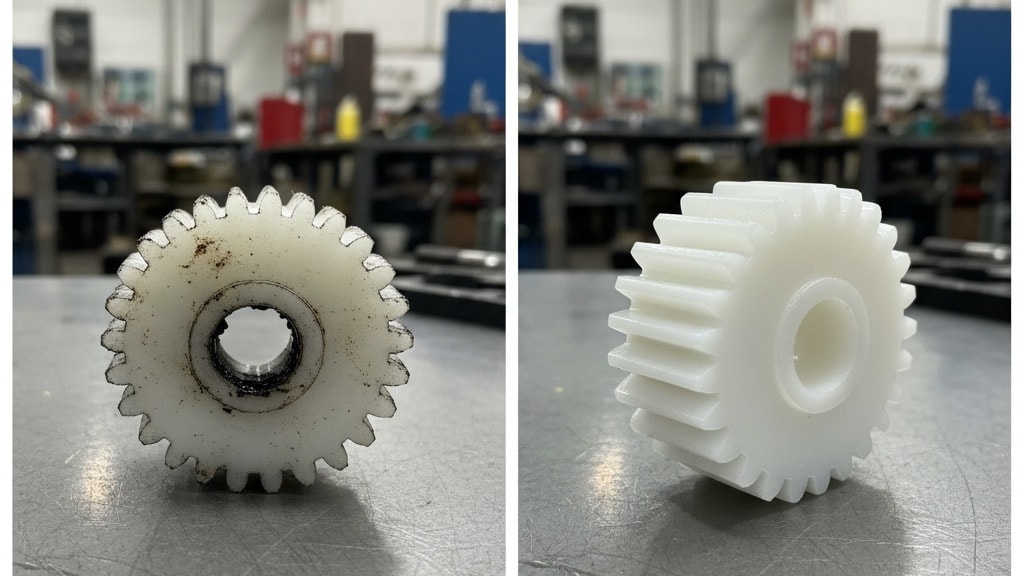

Nylon, it manifests a remarkable tenacity and non-porous smoothness, which facilitates efficient laser cleaning by preventing contaminant adhesion and preserving structural integrity.

When examining the contaminated Nylon surface at 1000x, you see dirt particles scattered across the fibers, creating a bumpy, uneven layer. Grime clings tightly to the edges, dulling the material's natural weave and hiding finer details. This buildup makes the whole texture look rough and obscured.

After laser treatment, the Nylon surface appears completely clear and smooth under 1000x view. Fibers stand out evenly now, without any clinging residues or rough spots. The clean finish

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more