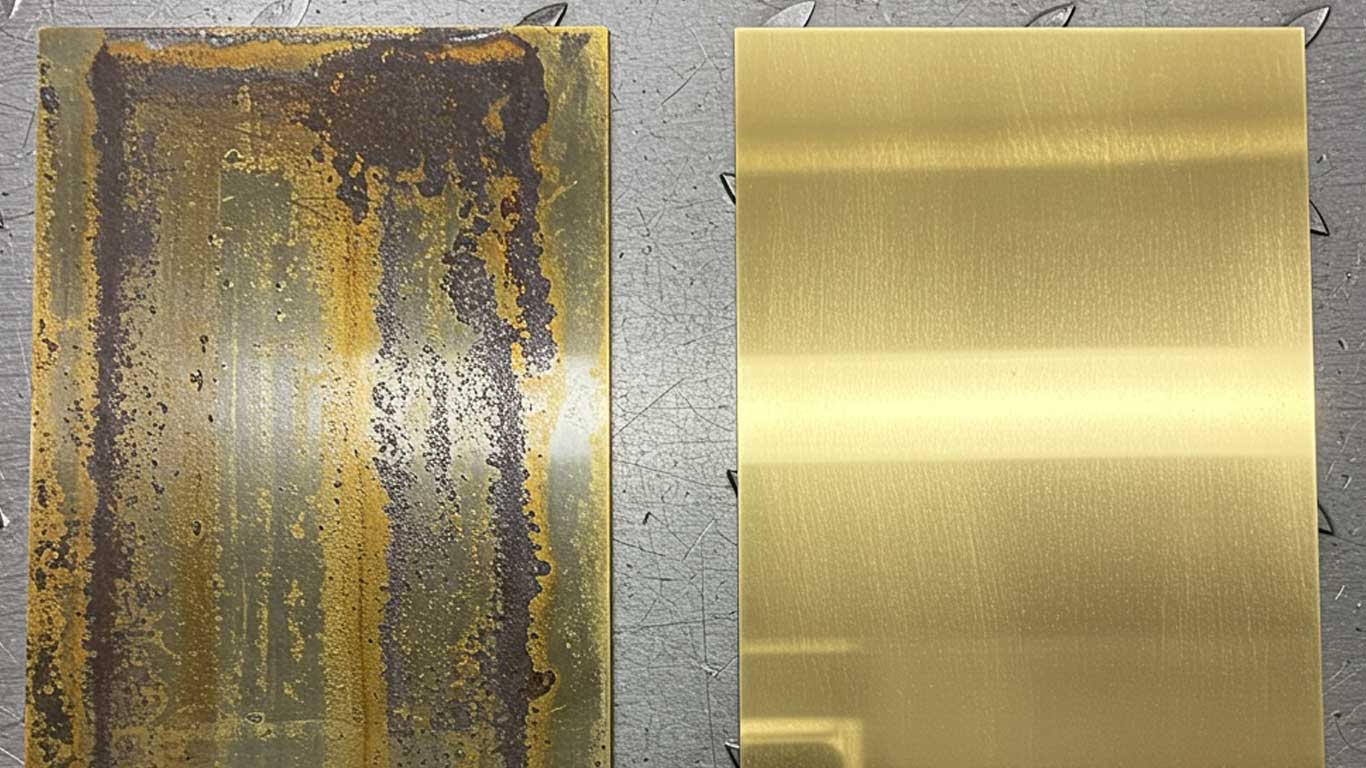

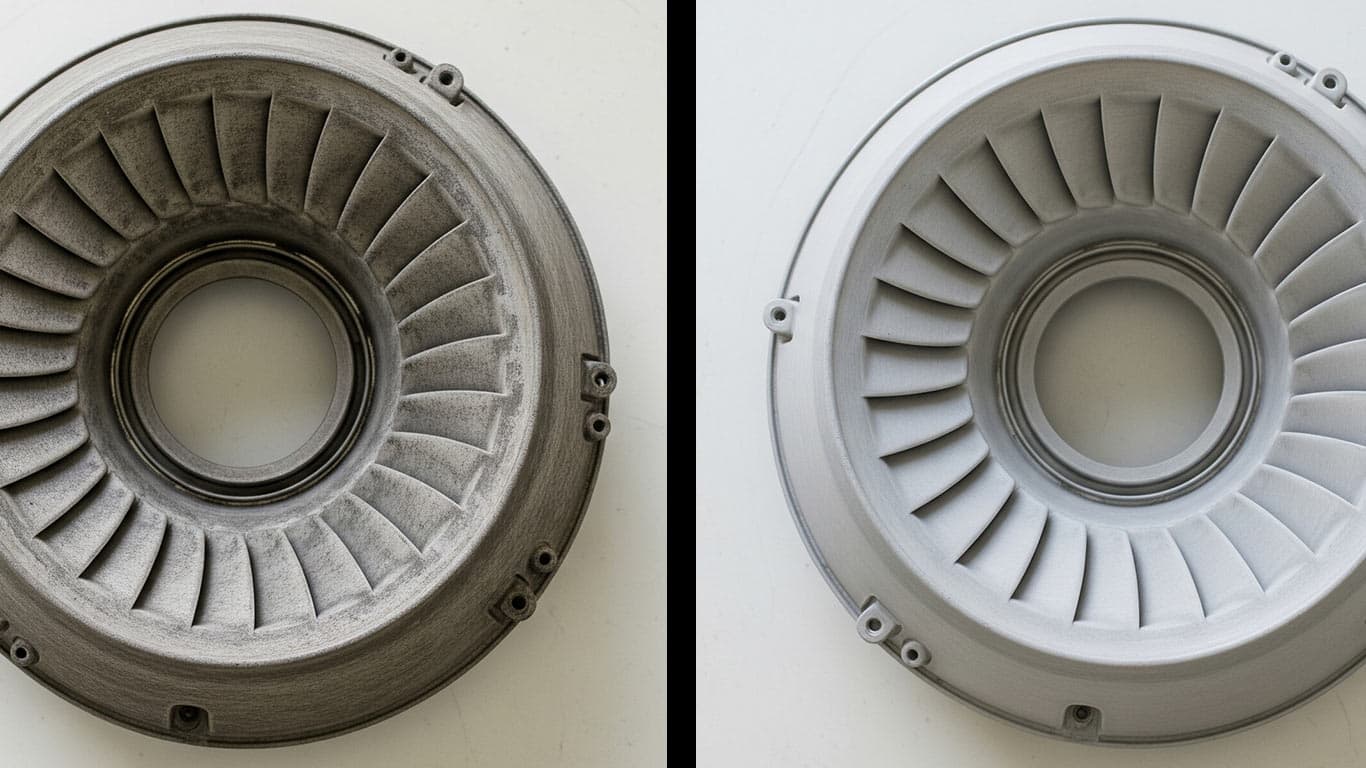

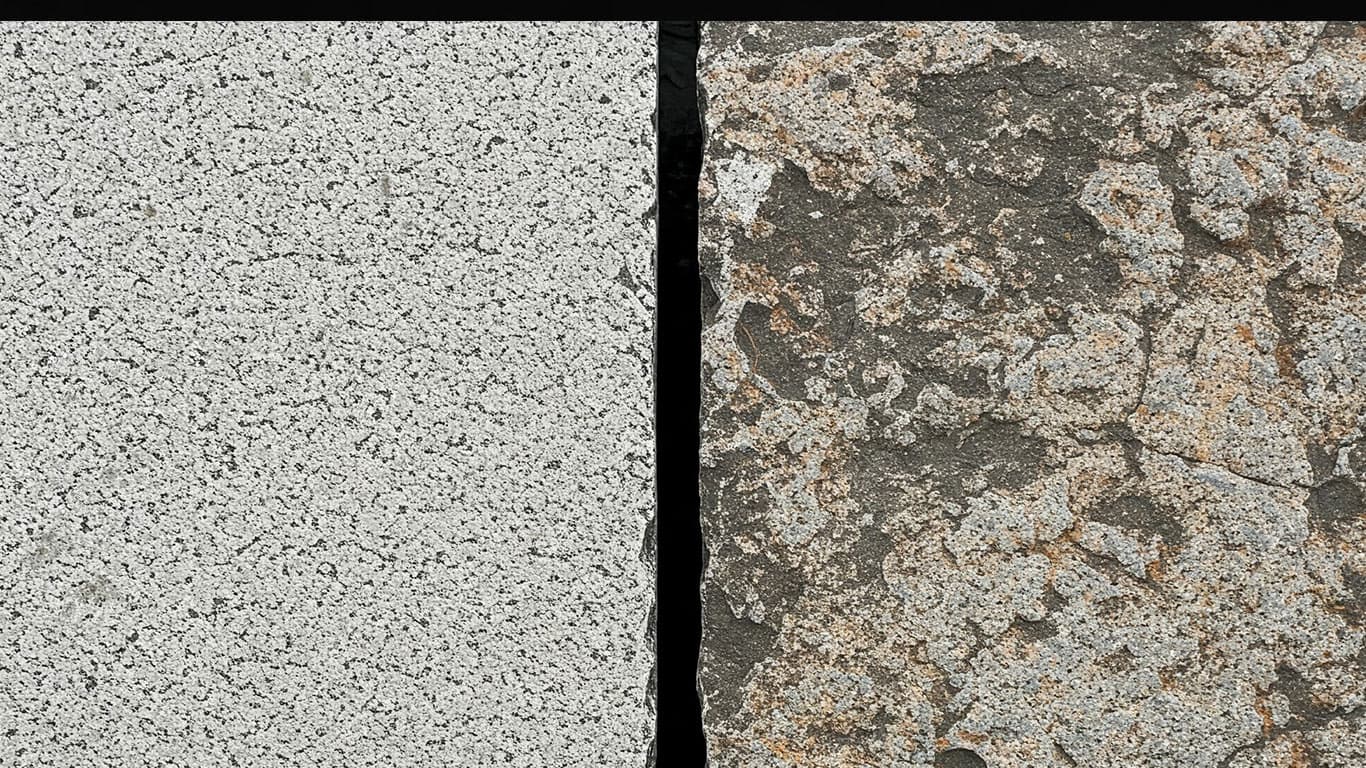

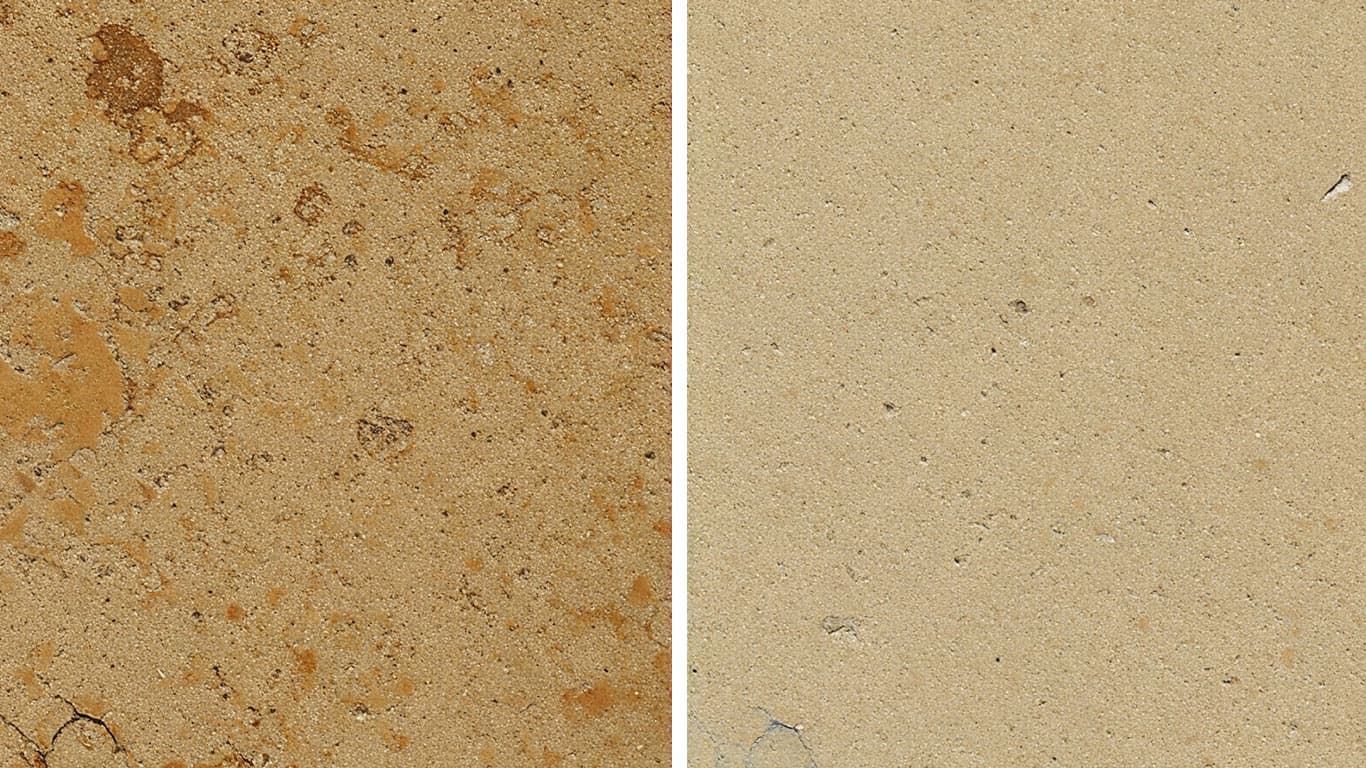

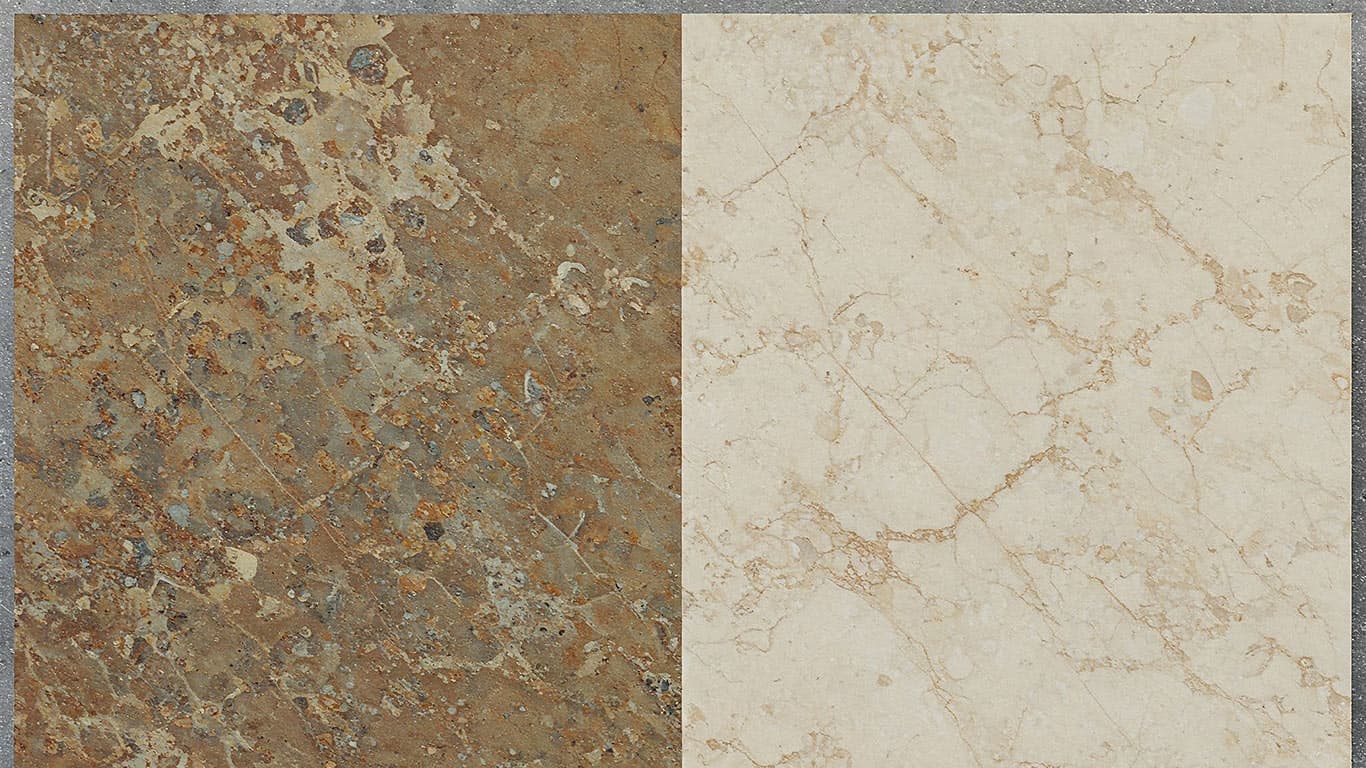

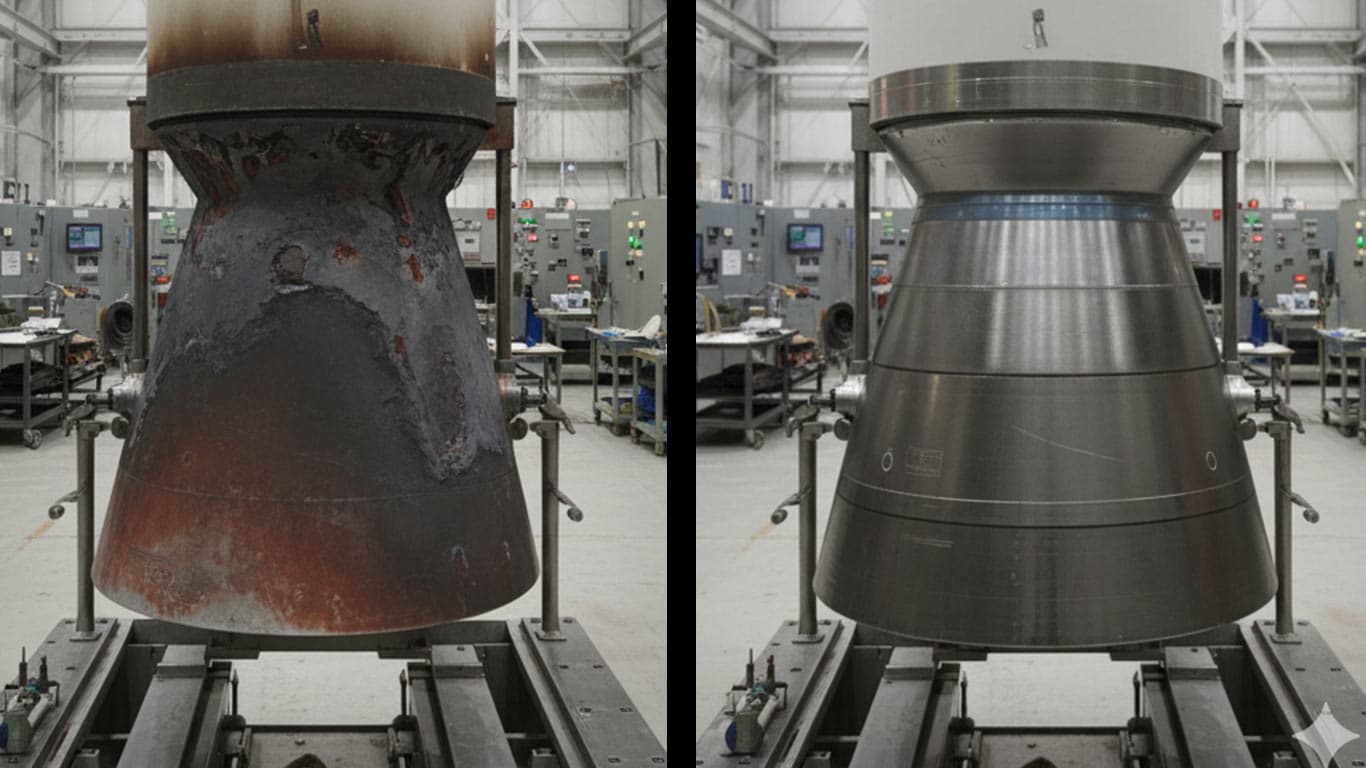

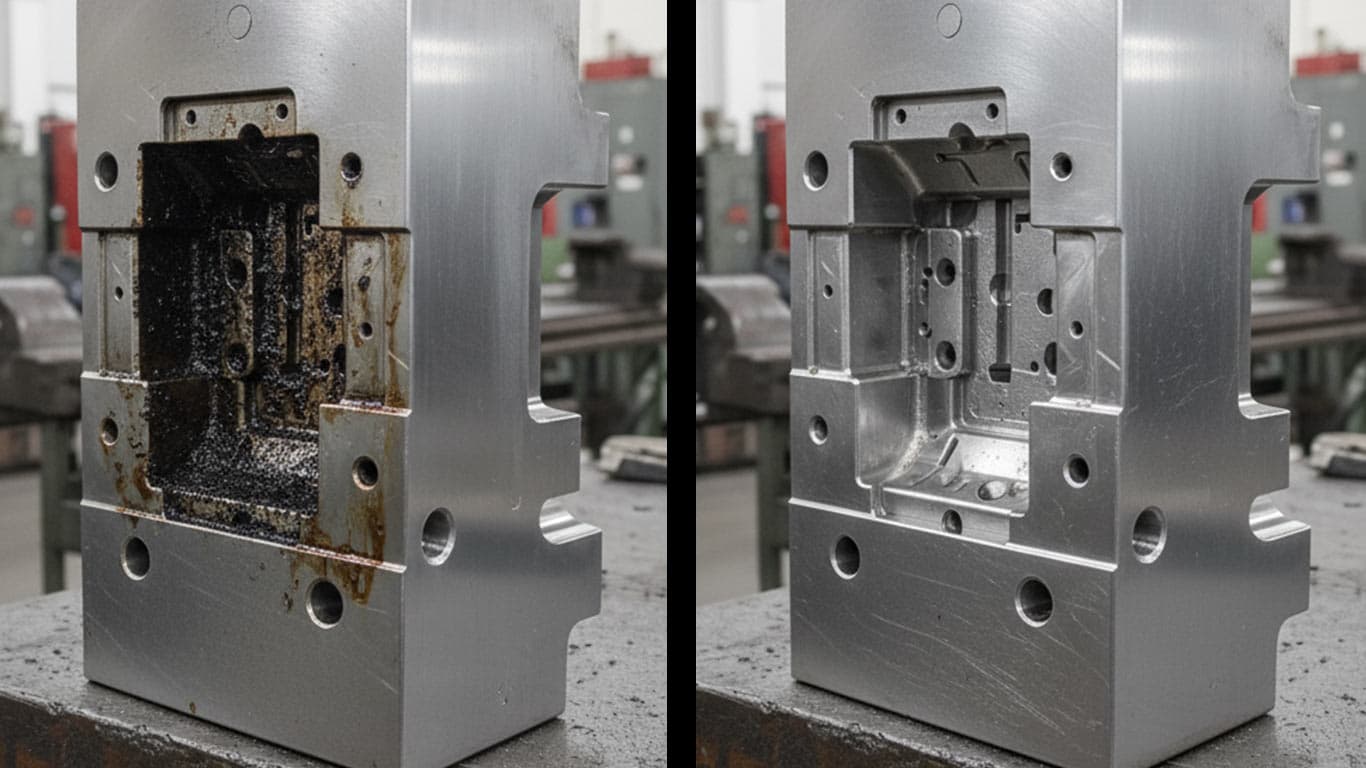

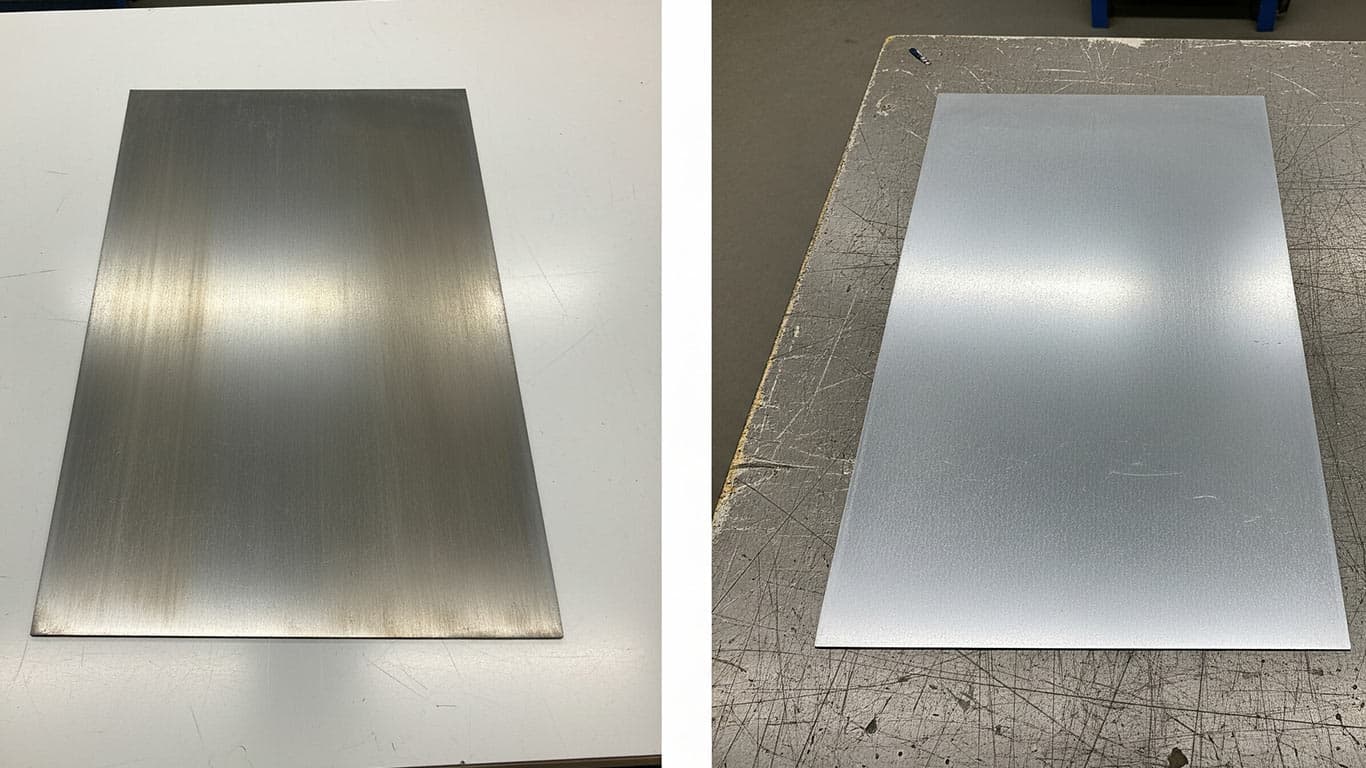

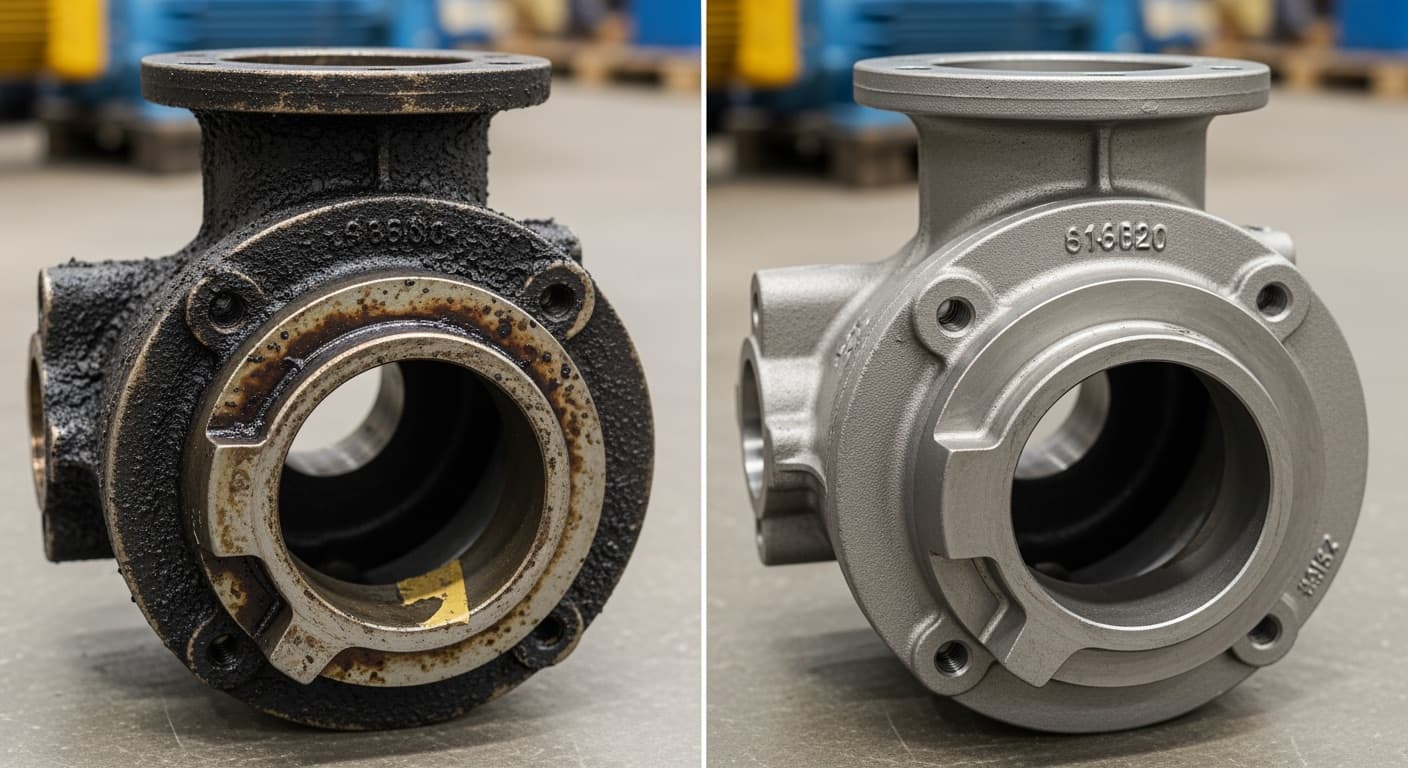

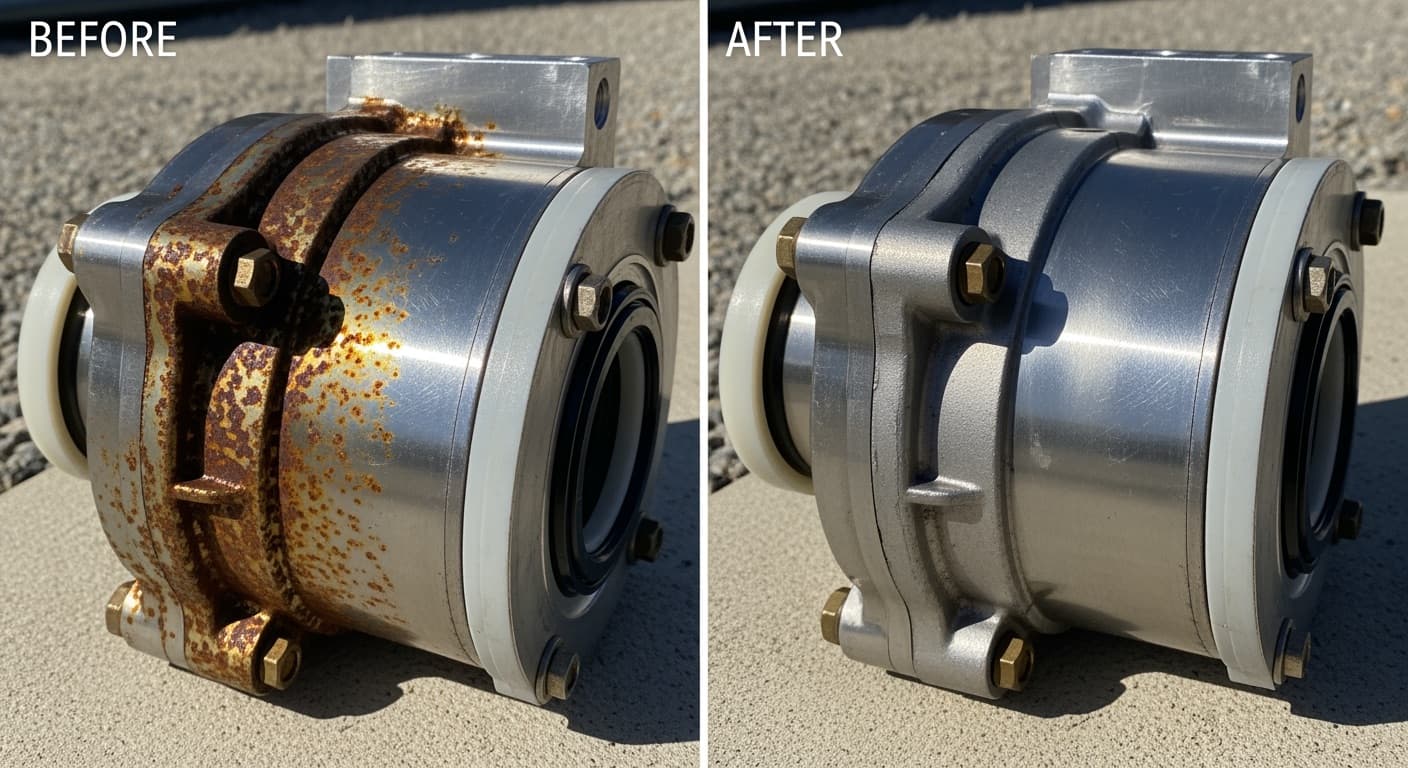

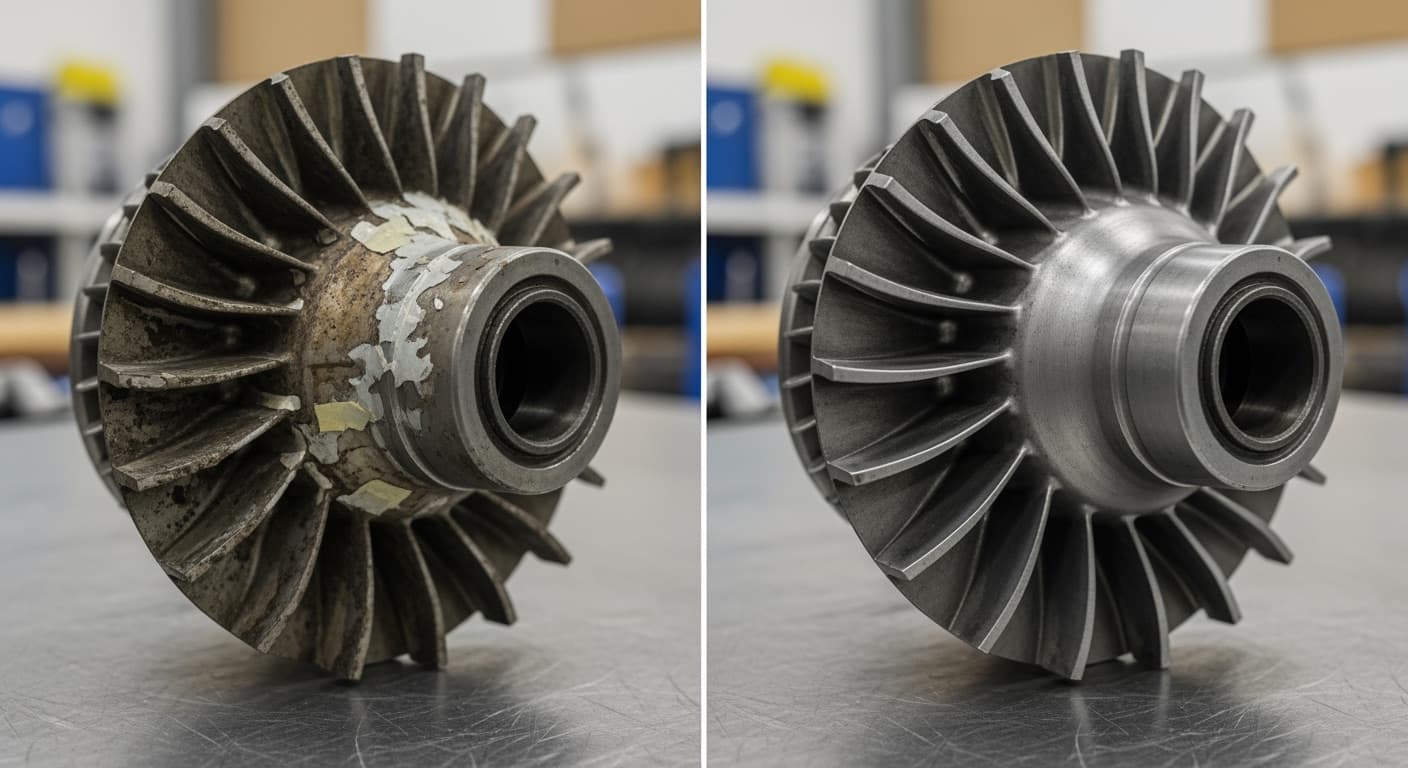

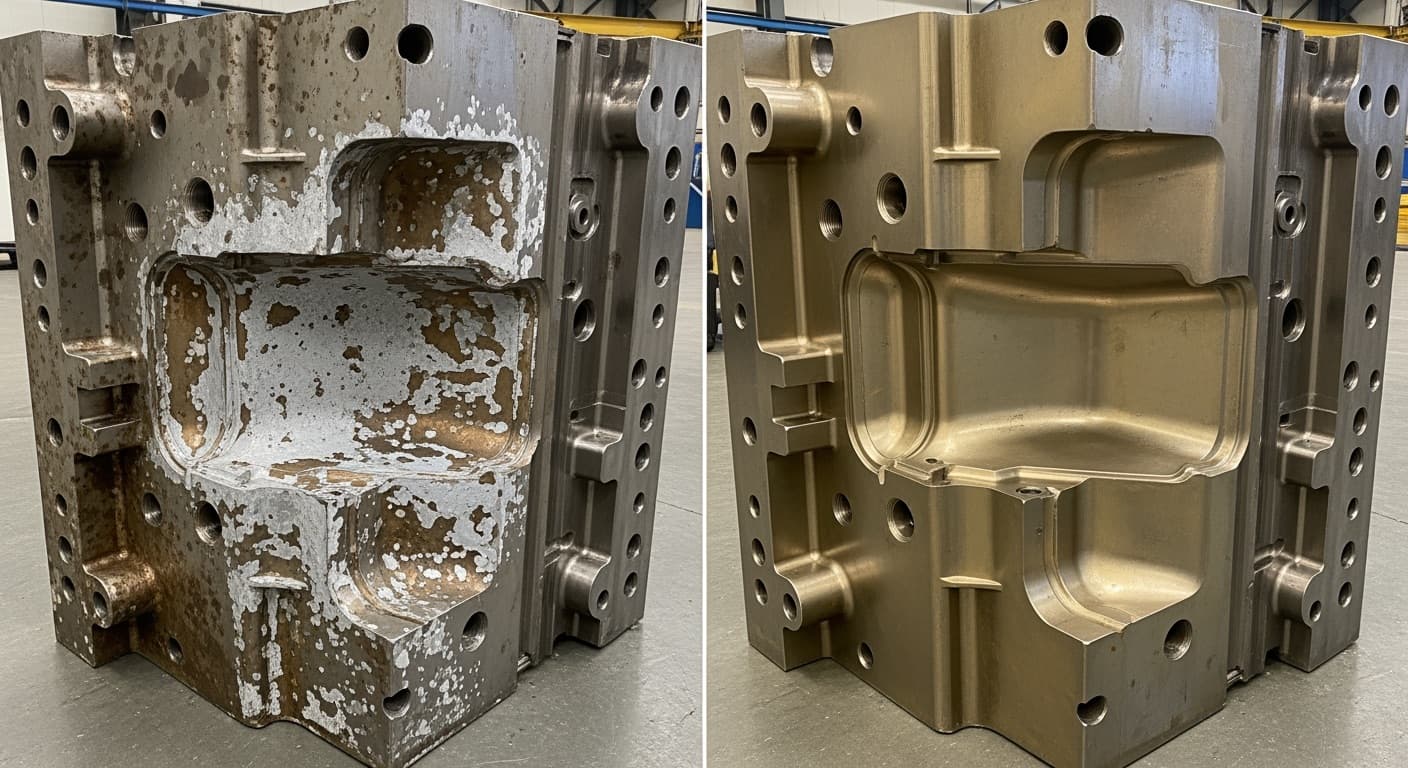

Before Treatment

Surface shows contamination from uv photodegradation / polymer chalking affecting material appearance and properties.

After Treatment

Post-cleaning reveals restored surface with uv photodegradation / polymer chalking successfully removed through precise laser ablation.