FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

When laser cleaning borosilicate glass, I've seen how its remarkable resistance to thermal shock allows steady energy pulses from the outset to gently remove residues and buildup, all without the risk of cracks or distortions, though it's wise to watch for any subtle surface heating to ensure everything stays intact.

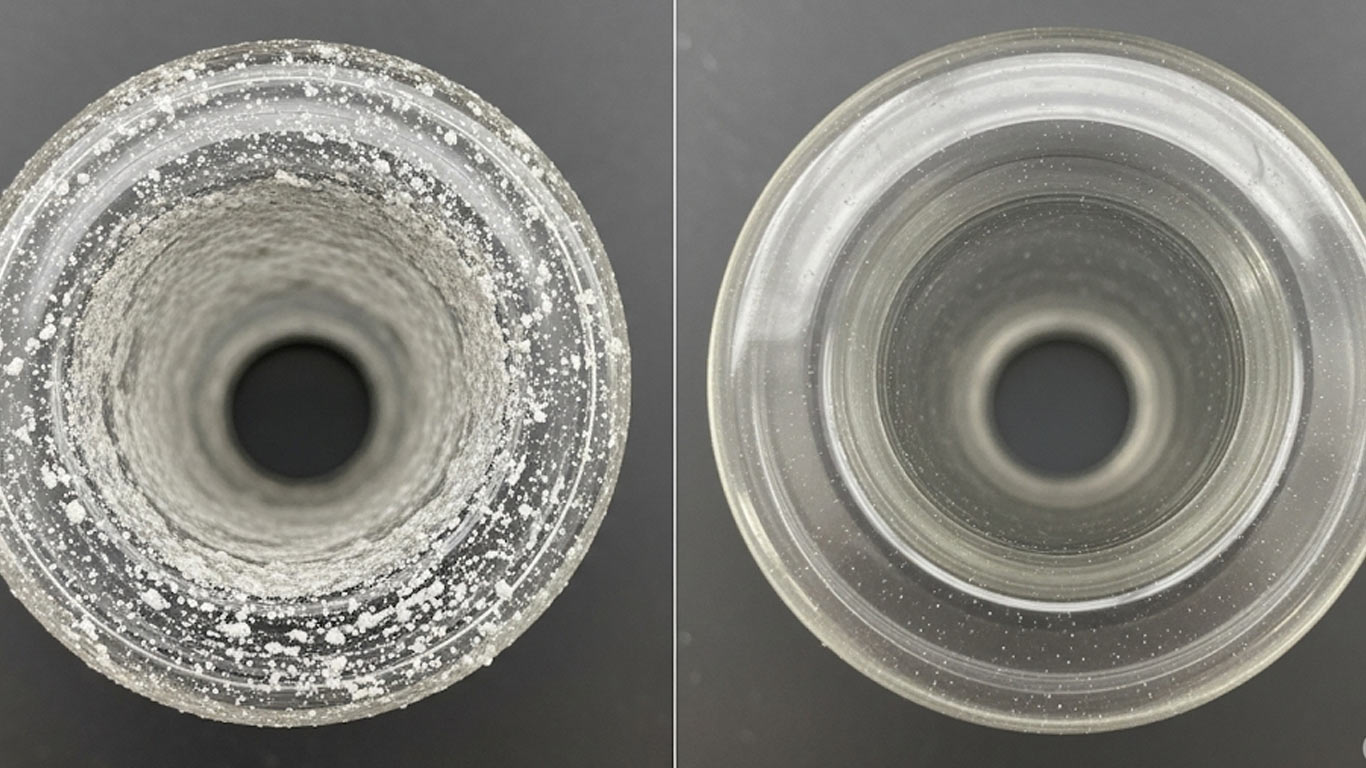

At 1000x magnification, the borosilicate glass surface shows heavy contamination with irregular spots and clinging debris. We notice thick, uneven layers of grime that obscure the underlying material completely. It appears rough and dull, hiding any natural smoothness beneath.

After laser treatment at the same magnification, the borosilicate glass surface reveals a spotless shine without lingering spots or debris. We've observed even, uniform layers that expose the material's true clarity fully. It looks smooth and vibrant, restoring its

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more