FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

When laser cleaning Gorilla Glass, start by setting the power low to avoid any risk of micro-cracks from its high thermal sensitivity, then gradually increase as its inherent toughness removes contaminants without compromising the surface integrity I've seen hold up in repeated electronics repairs.

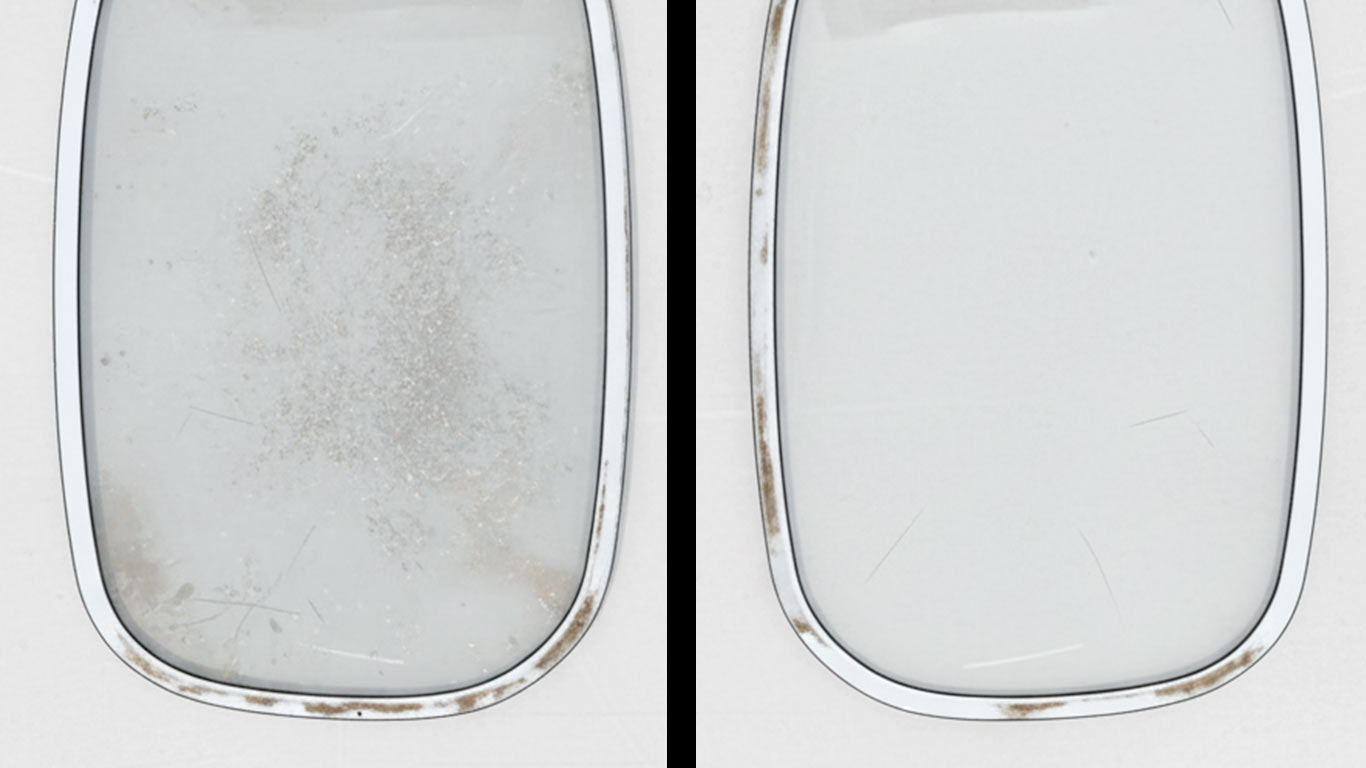

The contaminated surface reveals scattered patches of grime and dust that cling unevenly. Oily residues form irregular blobs, obscuring the glass's natural texture beneath. Fine debris particles dot the area, creating a mottled and rough overall look.

Laser treatment exposes a smooth expanse free of grime and clinging residues. The glass surface now gleams with uniform clarity, revealing its inherent polish. Subtle textures emerge cleanly, without any mottled spots or rough interruptions.

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more