FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

Molybdenum exhibits high heat resistance, so laser cleaning removes contaminants effectively without surface damage. During processing, its reflectivity challenges energy absorption, yet strong thermal shock tolerance ensures durability for aerospace parts. Treatment achieves clean uniformity.

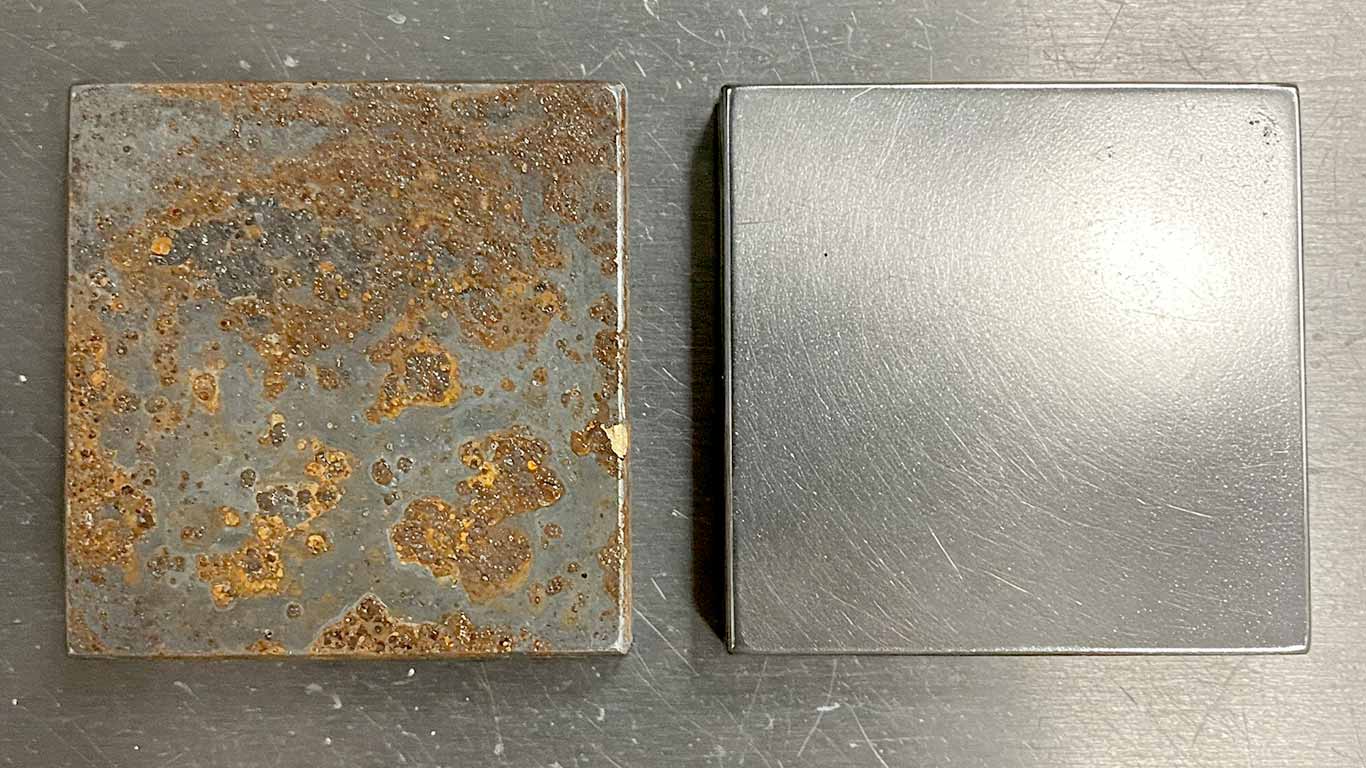

When we examine the contaminated molybdenum surface at high magnification, dark specks and uneven patches dominate the view. Layers of grime cling tightly, creating rough textures that obscure the base material. Scattered debris builds up in crevices, giving it a cluttered and worn appearance.

After laser treatment, the same surface reveals a smooth and uniform shine across its expanse. Clean lines emerge without any lingering spots or roughness. The material now appears polished and even, free from all visible buildup.

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more