FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

When laser cleaning polycarbonate, I've noticed the biggest hurdle is keeping heat from building up and warping softer plastics like acrylic, but this material's superior toughness and heat resistance mean it can take strong pulses without any distortion, letting you strip contaminants from aerospace components or medical devices while holding onto its clear finish and solid strength

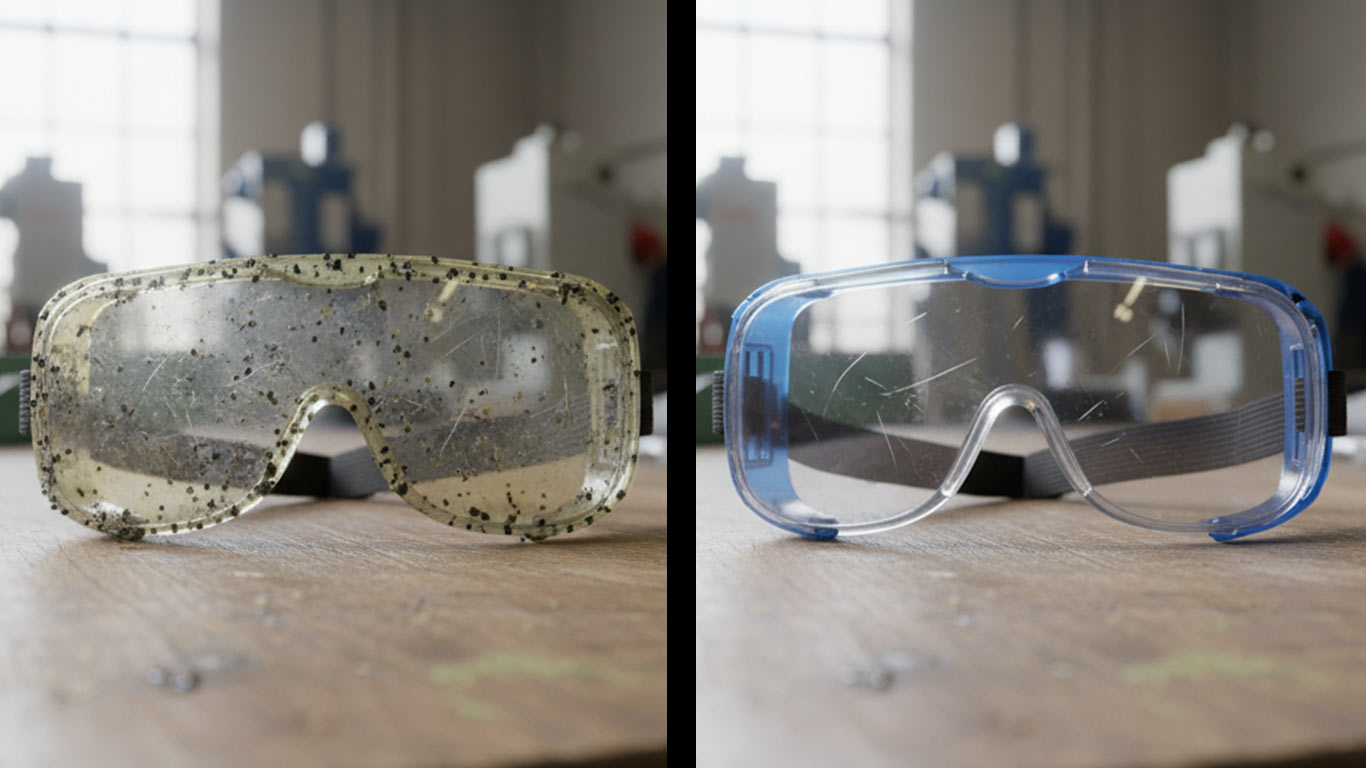

You see the polycarbonate surface covered in dark spots and uneven bumps. Dust and grime cling tightly, making the texture rough and patchy under high magnification. This contamination hides the material's natural smoothness and clarity.

After laser treatment, the surface looks even and bright without those spots. The texture turns smooth and uniform, revealing the clean, glossy finish underneath. Now the polycarbonate shines clearly, free from any clinging dirt.

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more