FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

When laser cleaning silver, start by dialing back the power to suit its mirror-like reflectivity, which bounces away most energy, while its top-notch thermal conductivity spreads any absorbed heat evenly across the surface to avoid localized melting and preserve the underlying structure—but always monitor closely to prevent unintended discoloration from prolonged exposure.

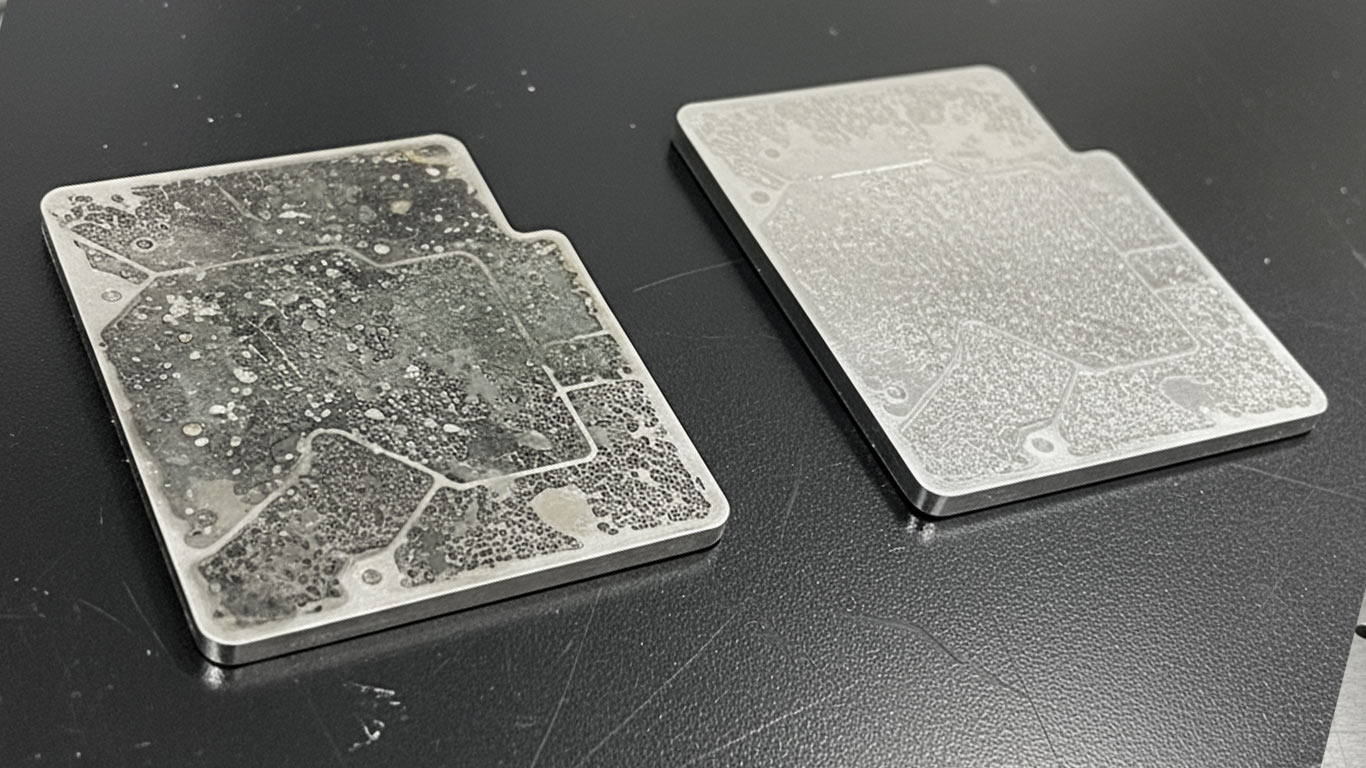

At 1000x magnification, the silver surface looks rough and covered in dark spots. Layers of grime cling tightly to every bump and crevice. This buildup hides the metal's true shine completely.

After laser treatment at the same view, you see a smooth and even surface emerge. The metal gleams with fresh clarity across its full area. Now it reflects light sharply without any trace of dirt.

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment