ANSI

ANSI Z136.1 - Safe Use of Lasers

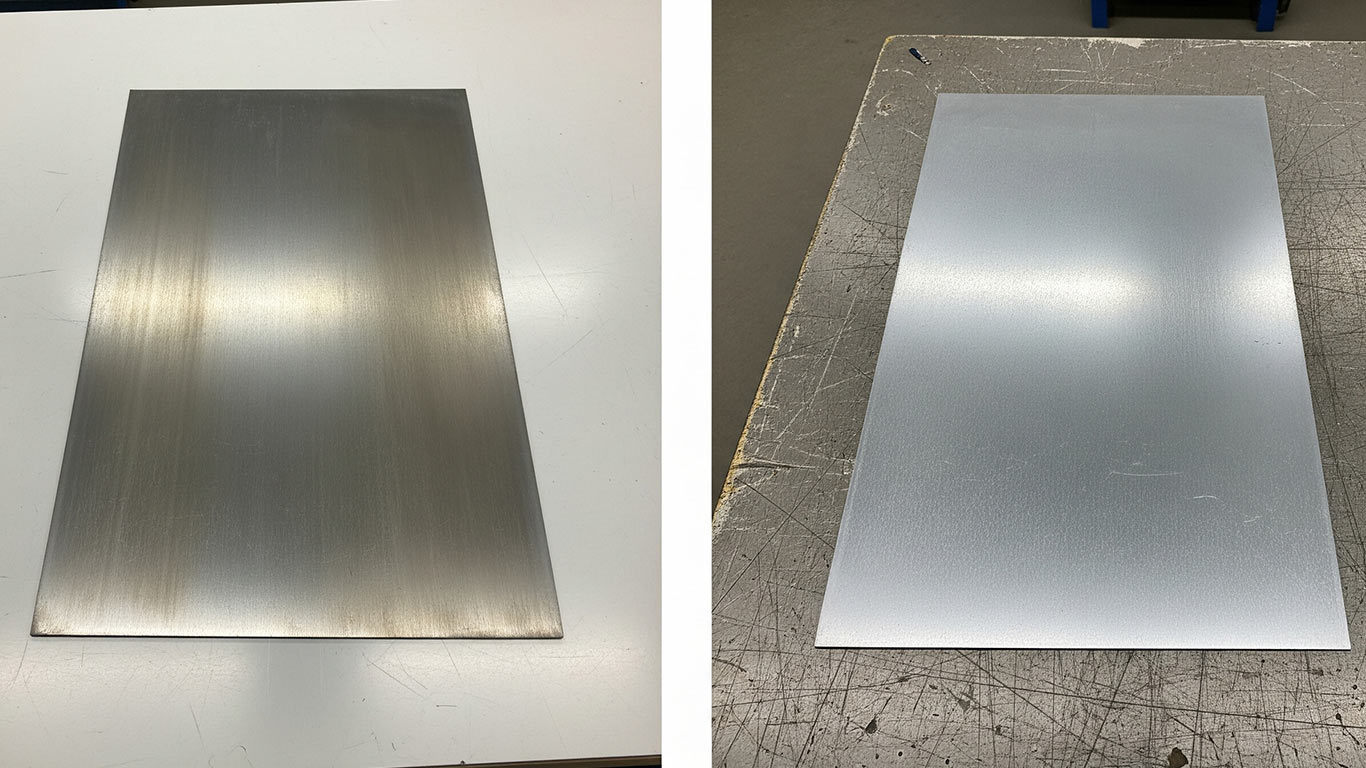

Zinc for laser cleaning, high reflectivity of material protects substrate from thermal damage. Contaminants absorb energy and vaporize easily, thus process yields clean surface without affecting underlying alloy, this sets zinc apart from absorptive metals that risk melting.

When examining the contaminated zinc surface at 1000x magnification, I've noticed irregular bumps and dark smudges everywhere. Grime layers build up thickly, dulling the metal's natural tone completely. These spots create a patchy, worn look that hides the underlying structure.

After laser treatment on the zinc surface at 1000x magnification, it appears smooth and evenly lit now. The clean areas reflect light brightly without any lingering marks. This polished finish reveals the metal's true clarity

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment