ANSI

ANSI Z136.1 - Safe Use of Lasers

For laser cleaning of tin, begin with low power to carefully manage its low melting point, in contrast to tougher metals that endure higher intensities without deformation.

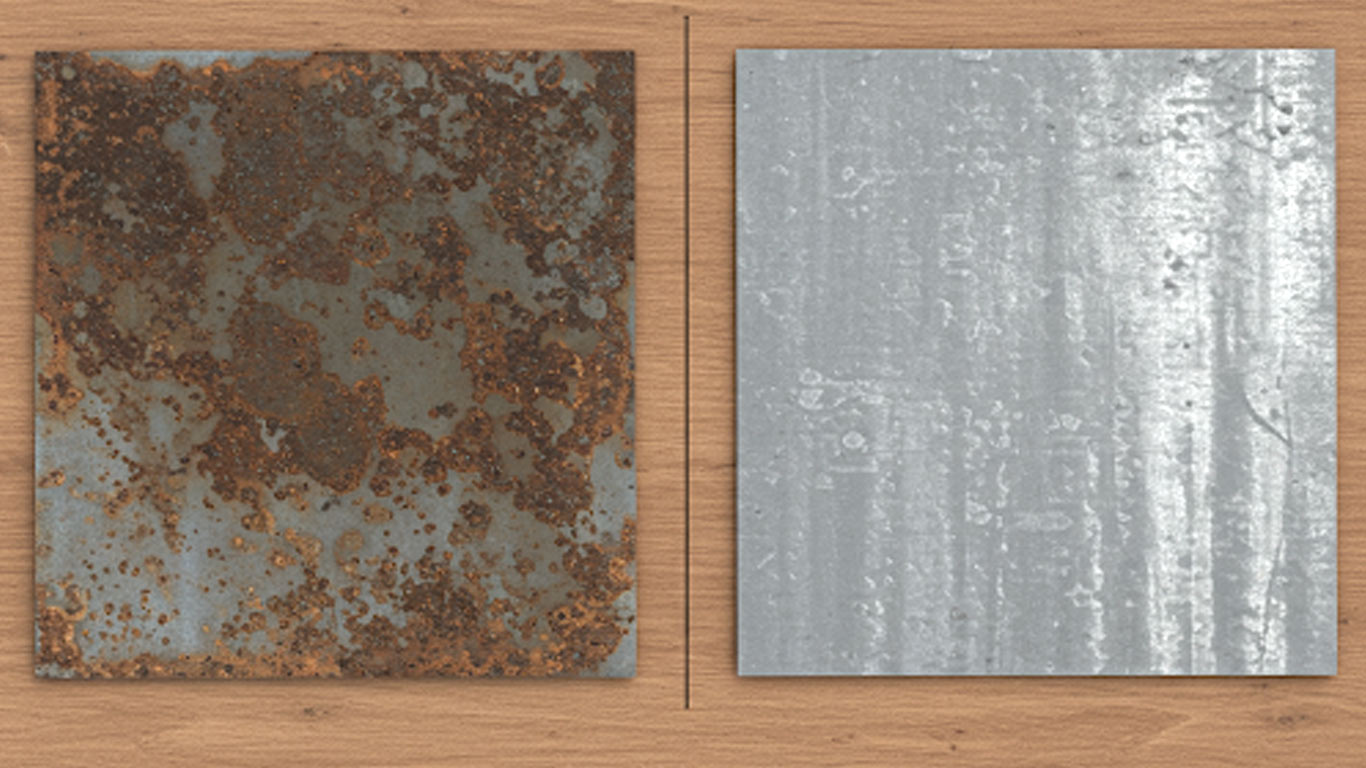

When we examine the tin surface before laser cleaning at 1000x magnification, dirty smudges cover most of it unevenly. Grimy particles cling tightly to the rough texture, making the whole area look dull and patchy. Scattered dark spots mar the base metal, hiding its natural shine completely.

After the laser treatment, the same view shows a smooth and even surface free from all grime. The metal gleams brightly now, with no rough patches or clinging debris left behind

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more