FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

When laser cleaning stainless steel 304, watch out for how it holds heat longer than carbon steels. I've seen that cause uneven surfaces if you push too hard. But its strong corrosion resistance really sets it apart, restoring a clean finish that stays protected longer. This works best with short, steady pulses.

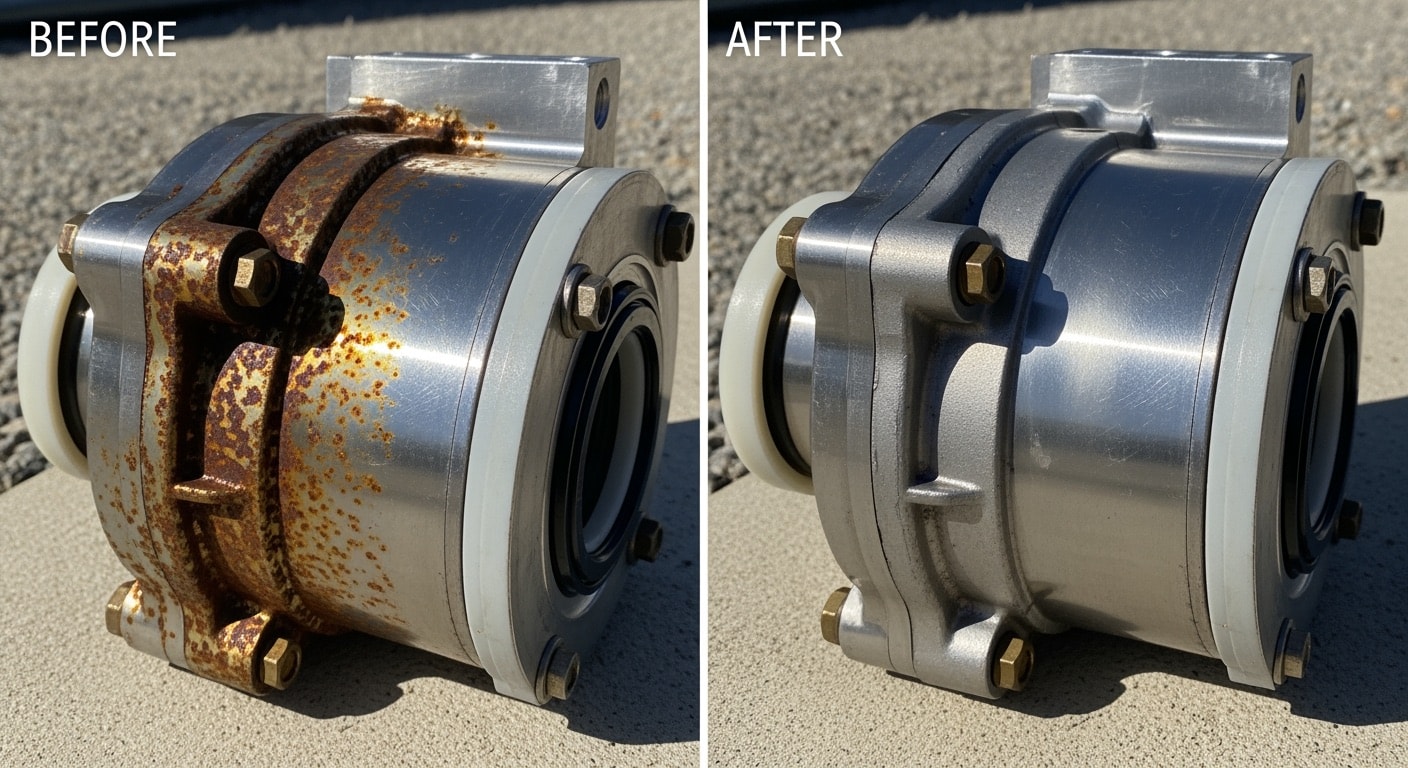

The contaminated surface reveals irregular patches of dark residue clinging to the metal grains. Scattered specks of debris create uneven textures across the field of view. Rough edges and embedded particles obscure the underlying structure.

Laser treatment restores a uniform shine to the exposed metal grains. Smooth contours replace the former debris, revealing clear boundaries between grains. The cleaned area displays consistent reflectivity without lingering irregularities.

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more