FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

Titanium alloy Ti-6Al-4V shows superior corrosion resistance and high strength, so laser cleaning removes surface contaminants effectively while surface maintains durability for industrial uses.

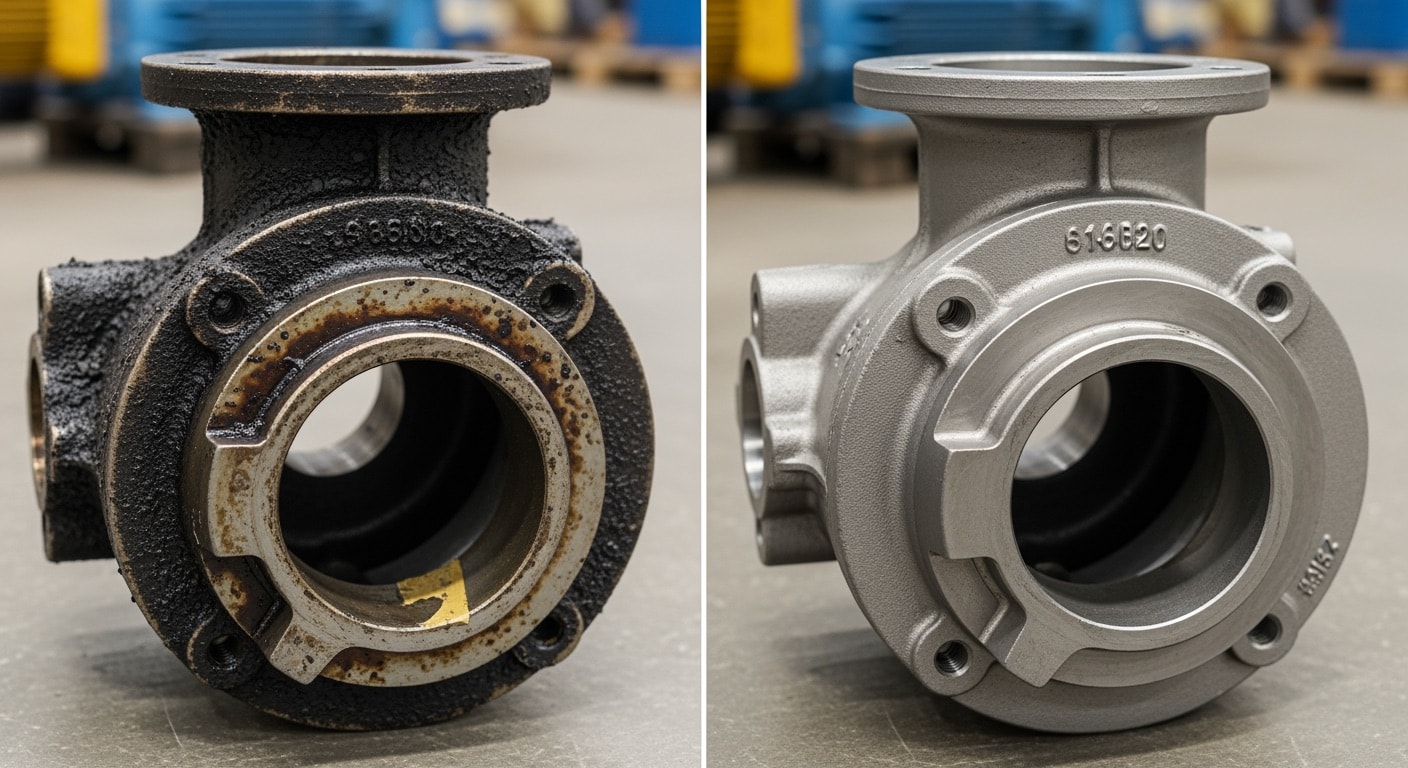

We've found the contaminated surface on this titanium alloy shows heavy buildup. Dark spots and uneven layers cover the base material completely. Scratches and debris make the texture look rough and cluttered.

After laser treatment, the surface appears smooth and uniform. We see no remaining spots or layers now. The clean material shines evenly under magnification.

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more