ANSI

ANSI Z136.1 - Safe Use of Lasers

Tool steel excels with its exceptional hardness and heat resistance, allowing tools to keep sharp edges intact during intense machining operations without deforming or weakening.

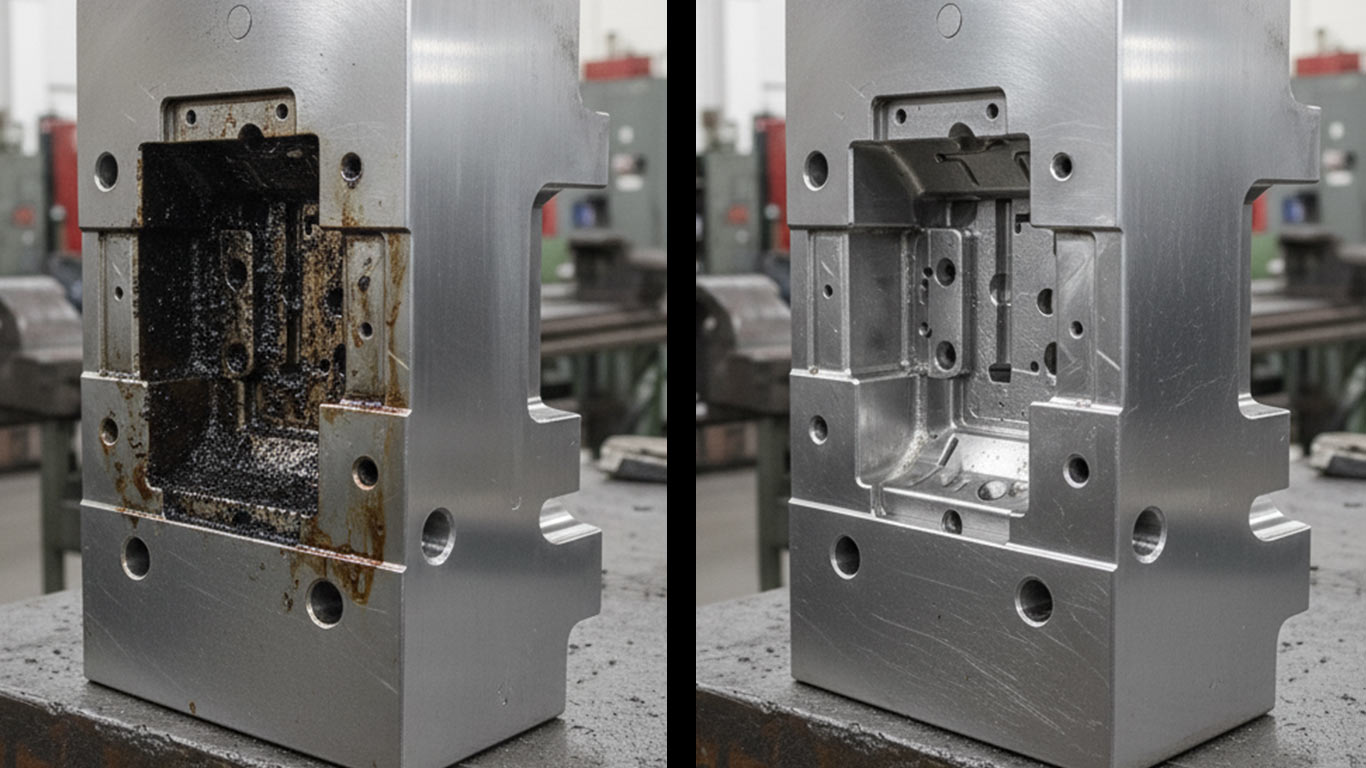

At 1000x magnification, the tool steel surface looks rough and patchy. Dark spots cluster together, trapping dirt and debris in cracks. This uneven layer hides the metal's true texture underneath.

After laser treatment at 1000x, the tool steel surface shines smooth and even. No spots remain, and cracks disappear into a clean polish. This fresh layer reveals the metal's solid, uniform structure.

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more