ANSI

ANSI Z136.1 - Safe Use of Lasers

When laser cleaning vanadium alloys, I've seen how their natural corrosion resistance keeps surfaces intact even under intense pulses, so you start with moderate power to gently lift contaminants without risking the underlying strength that makes them ideal for aerospace parts and chemical gear.

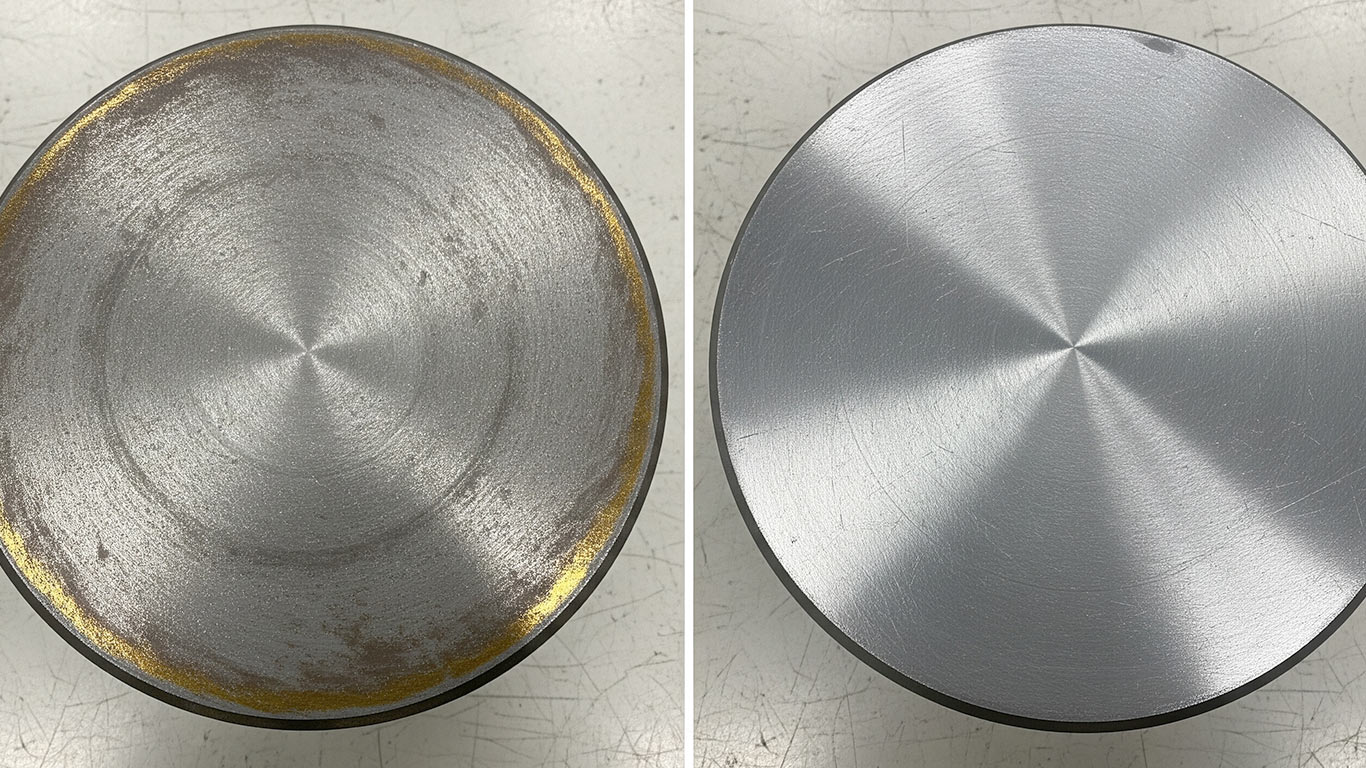

Looking at the vanadium surface before cleaning under high magnification reveals a cluttered mess of contaminants clinging tightly. Dark residues and scattered particles create an uneven, bumpy texture that hides the metal's true form. It all looks dull and choked, with layers building up in irregular spots.

After the laser treatment, that same vanadium surface transforms into a clear, smooth expanse free of any buildup. Fine metallic grains stand out sharply now, without the old debris interrupting. The whole area gleams evenly and feels polished

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more