FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

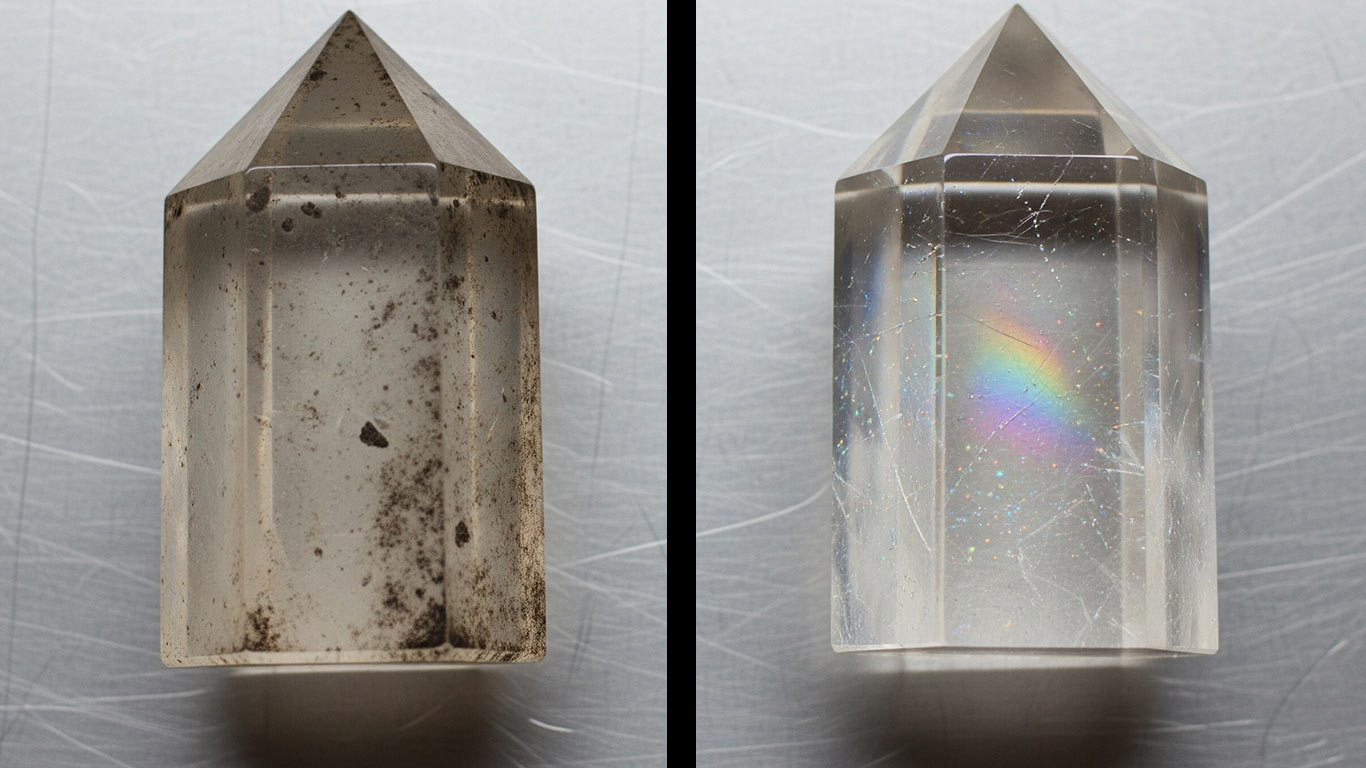

Quartz glass shows transparency and heat resistance in laser cleaning. This material resists damage from beams, thus enables precise removal of contaminants on surfaces. Challenges arise from brittleness, so careful parameter adjustment follows for effective processing.

When examining the contaminated quartz glass surface at 1000x magnification, you must notice the uneven layer of debris scattered across it right away. Tiny particles cling tightly, creating rough patches and dull spots that obscure the underlying clarity. This buildup makes the whole area look hazy and irregular, blocking any smooth view underneath.

After the laser treatment on the quartz glass surface at 1000x magnification, you see a sharp contrast in cleanliness. The once-cluttered spots now appear smooth and even

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment