FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

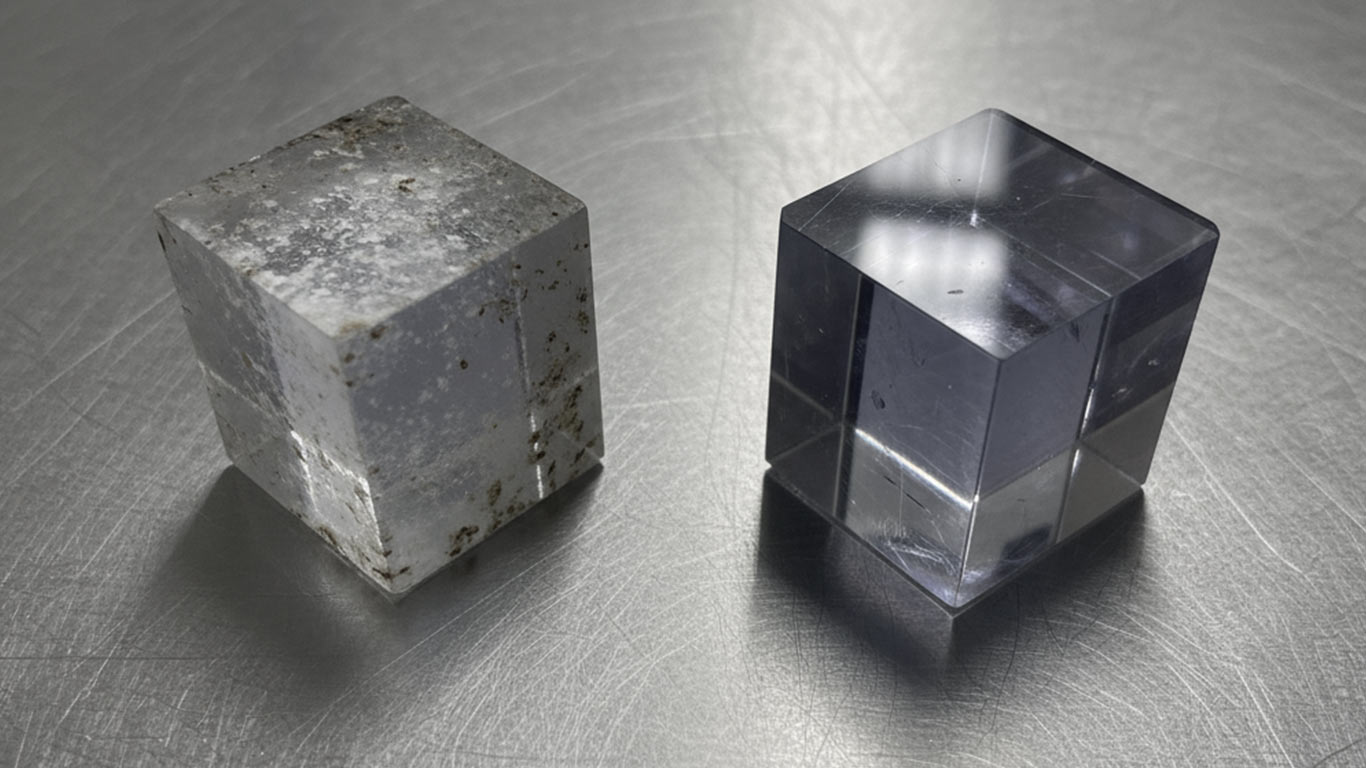

Sapphire glass provides exceptional scratch resistance that protects sensitive surfaces in watches and devices much better than regular glass, maintaining clear visibility and durability even with intense daily use

At 1000x magnification, the sapphire glass surface looks rough and cluttered with dark specks scattered everywhere. Fine particles cling tightly to the texture, creating uneven patches that block the smooth underlying shine. Dirt streaks run across the area, making the whole view hazy and obscured.

After laser treatment, the same sapphire glass surface appears crisp and uniform under 1000x magnification. The once-cluttered spots now reveal a flawless, mirror-like polish without any residue. Clear edges emerge sharply

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment