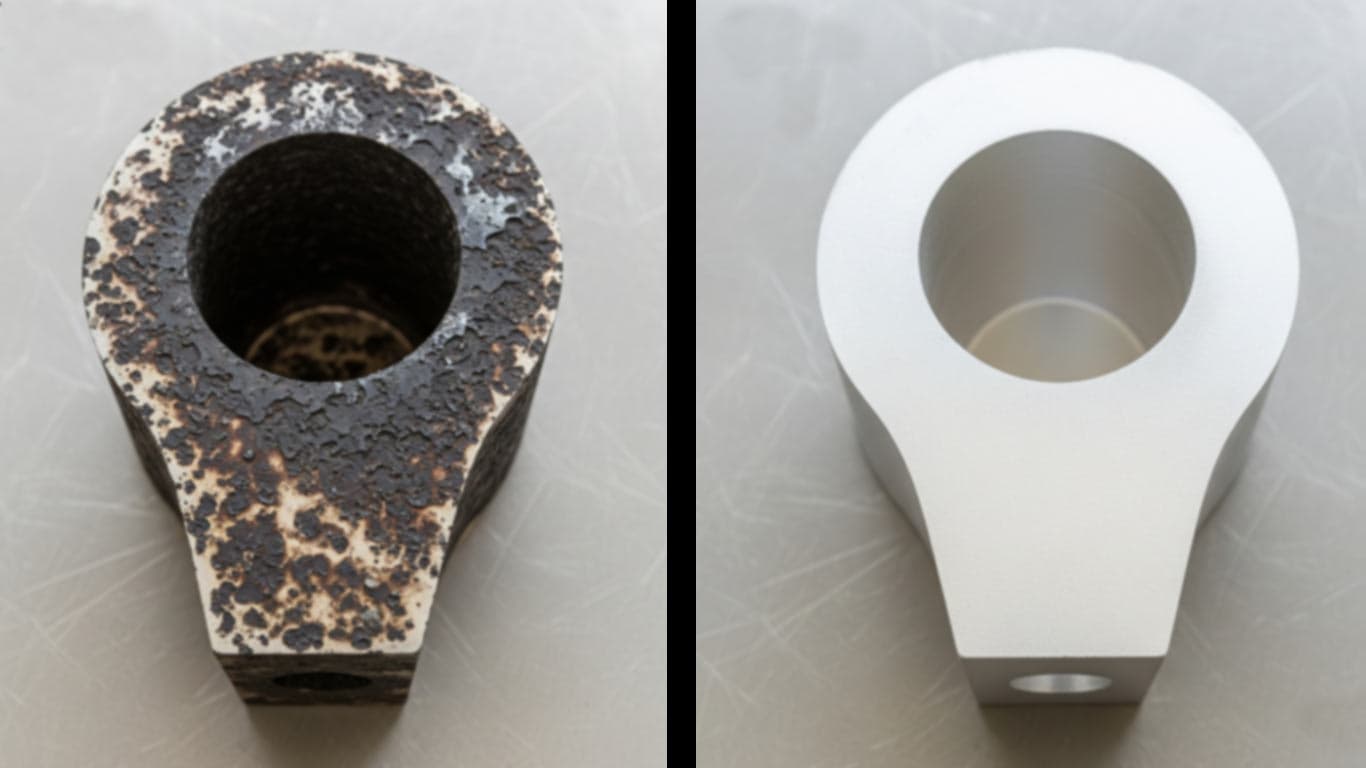

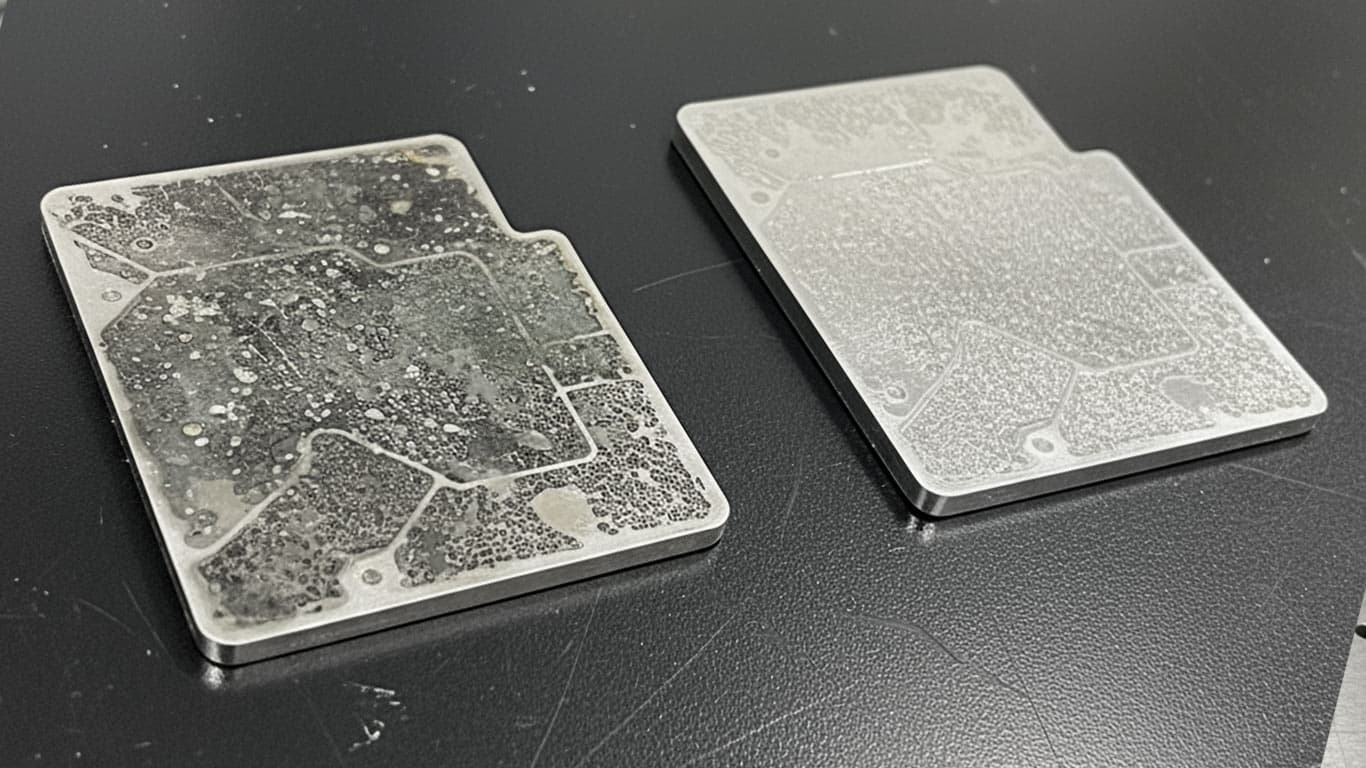

Before Treatment

Surface shows contamination from copper patina / verdigris affecting material appearance and properties.

After Treatment

Post-cleaning reveals restored surface with copper patina / verdigris successfully removed through precise laser ablation.