FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

When laser cleaning platinum, begin by adjusting the beam intensity to counter its high reflectivity, allowing you to remove contaminants efficiently and restore its clean surface for important roles in chemical processing or medical implants.

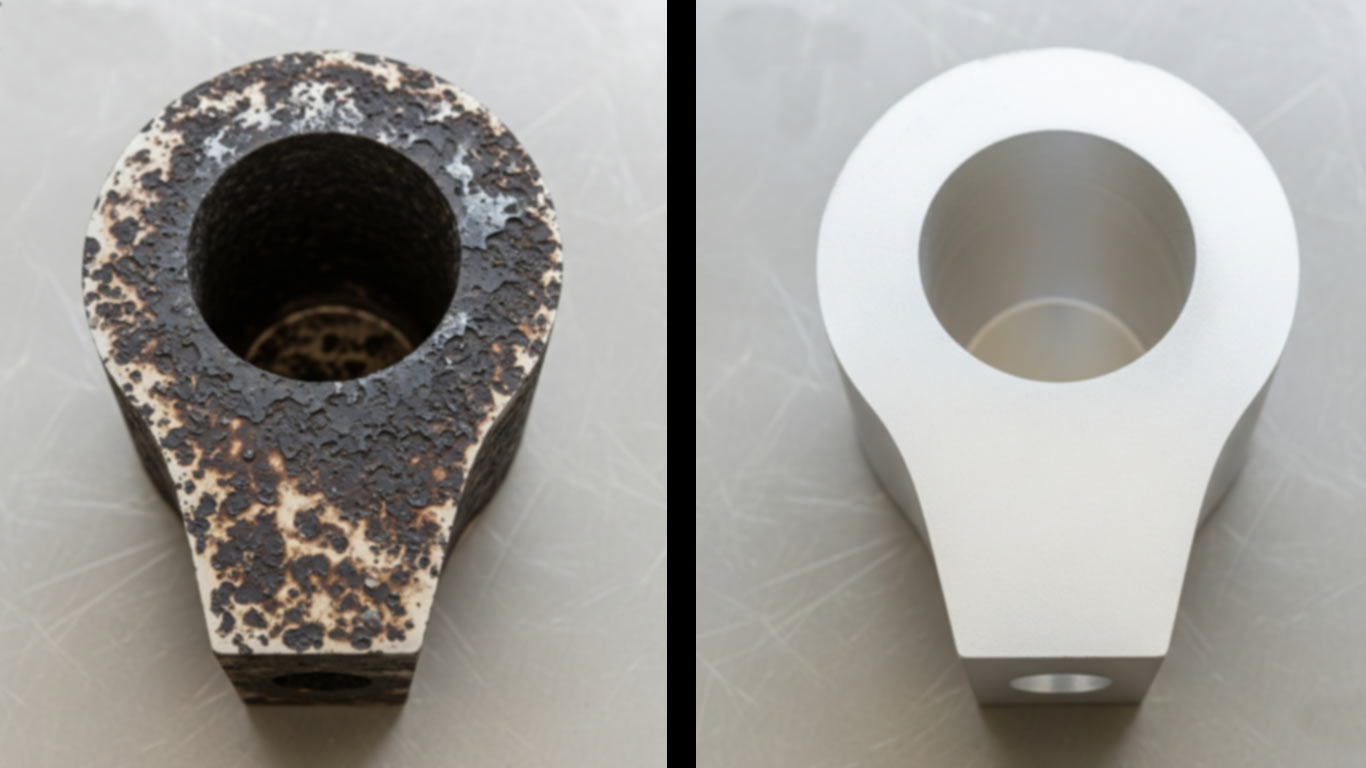

I've seen platinum surfaces get really grimy before cleaning, with dark smudges dotting the metallic sheen unevenly across the whole area. Particles cling tightly, making the texture bumpy and dull under magnification, almost hiding the underlying luster. Tends to show scratches too, pulling focus from the metal's natural smoothness.

After laser treatment, the same spot gleams with a uniform polish that restores its bright, even finish completely. No more clinging debris mars the view; everything looks crisp and

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more