FDA

FDA 21 CFR 1040.10 - Laser Product Performance Standards

When laser cleaning marble, I've found it keeps its elegant veins steady through low-energy passes that strip away grime mid-process, all without risking cracks from excess heat buildup.

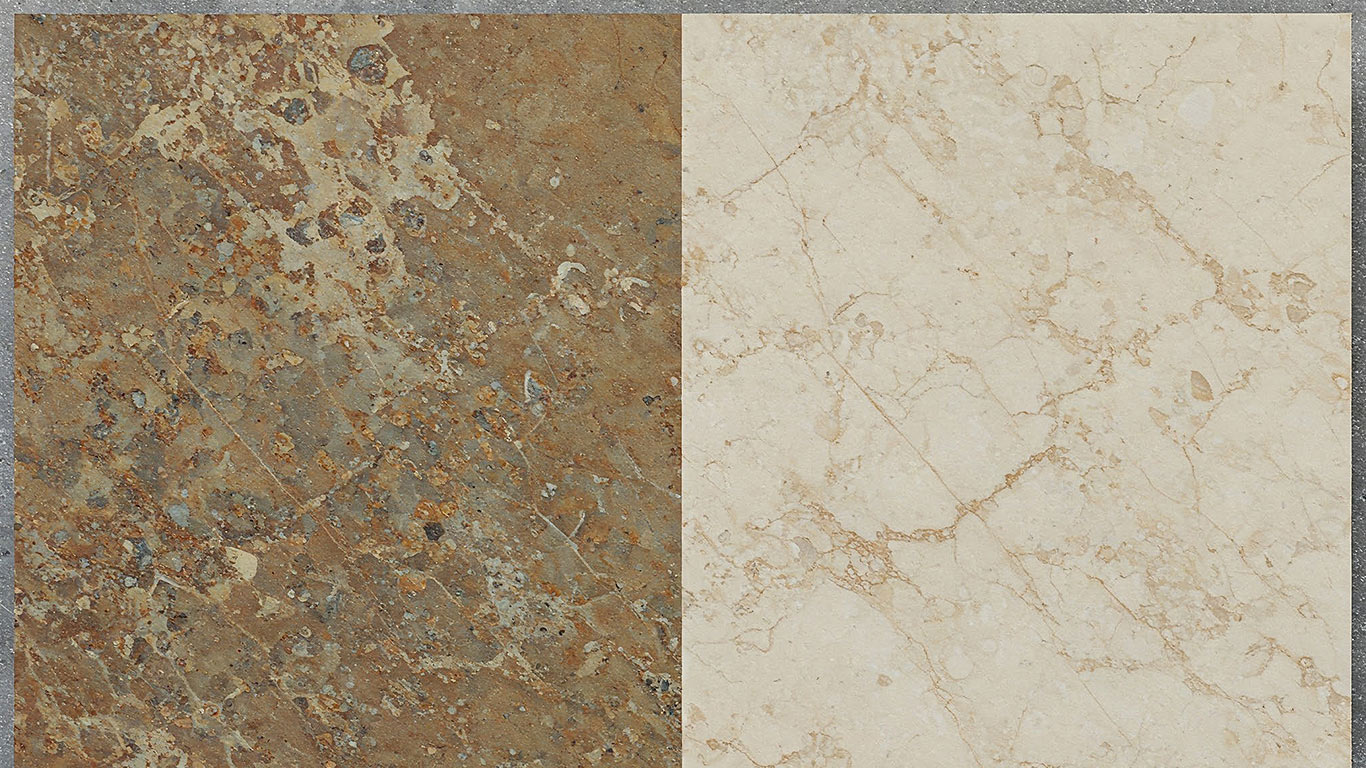

When examining the contaminated marble surface at high magnification, I've noticed layers of dark grime clinging tightly to the stone's uneven texture. Dust particles scatter across the pits and cracks, making the whole area look dull and patchy under the light. This buildup hides the natural patterns, turning what should be smooth into a rough, obscured mess.

After the laser treatment, the same surface appears refreshed and even, with the grime completely lifted away. The stone's original veins and colors shine through clearly

FDA 21 CFR 1040.10 - Laser Product Performance Standards

ANSI Z136.1 - Safe Use of Lasers

IEC 60825 - Safety of Laser Products

OSHA 29 CFR 1926.95 - Personal Protective Equipment

EPA Clean Air Act Compliance

ASTM C503 - Standard Specification for Marble Dimension Stone

UNESCO Guidelines for Cultural Heritage Conservation

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more