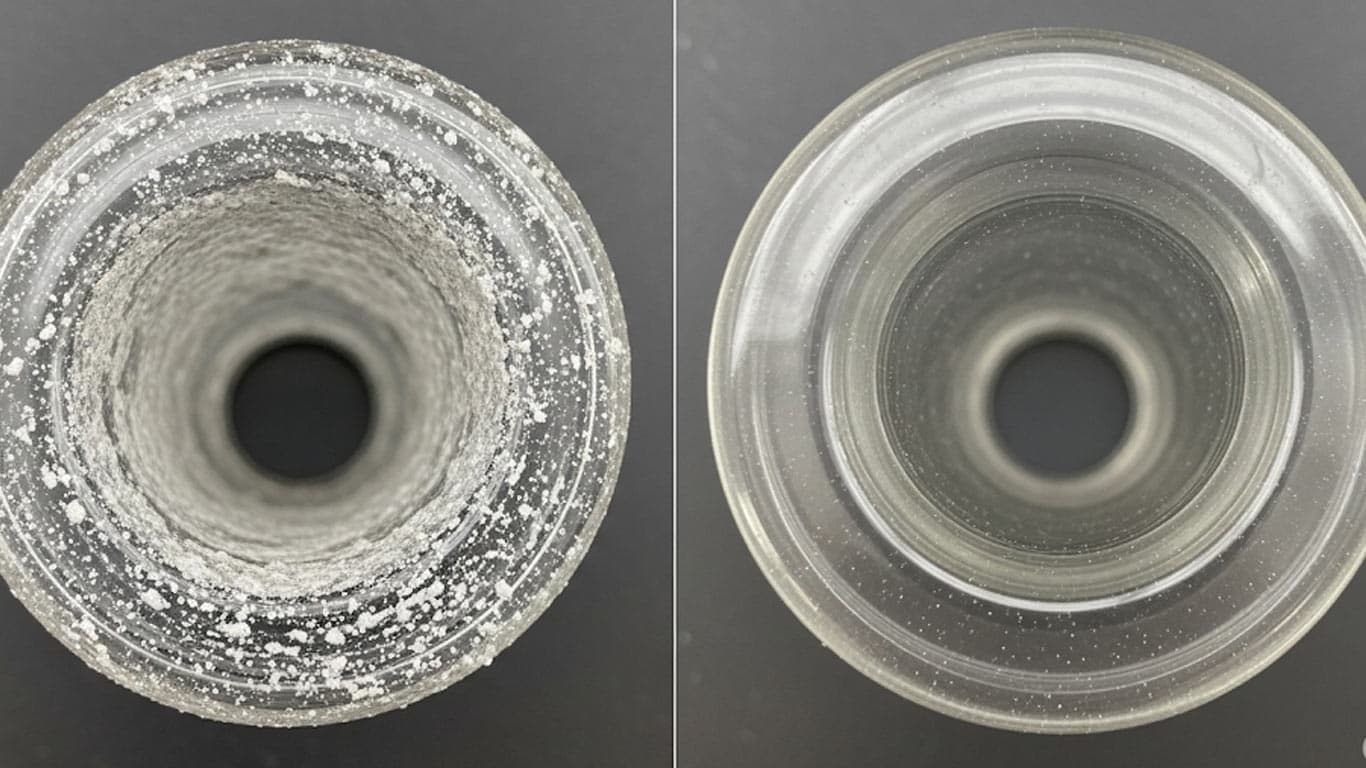

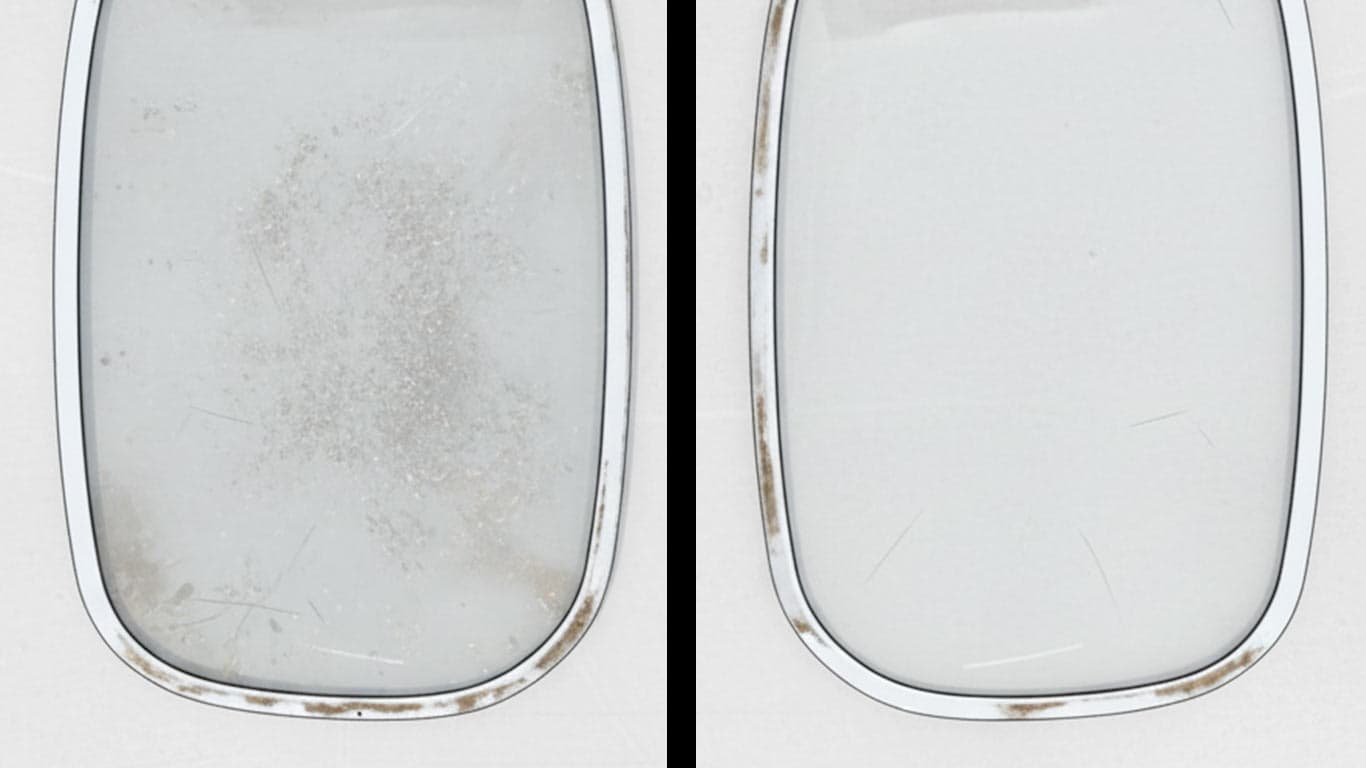

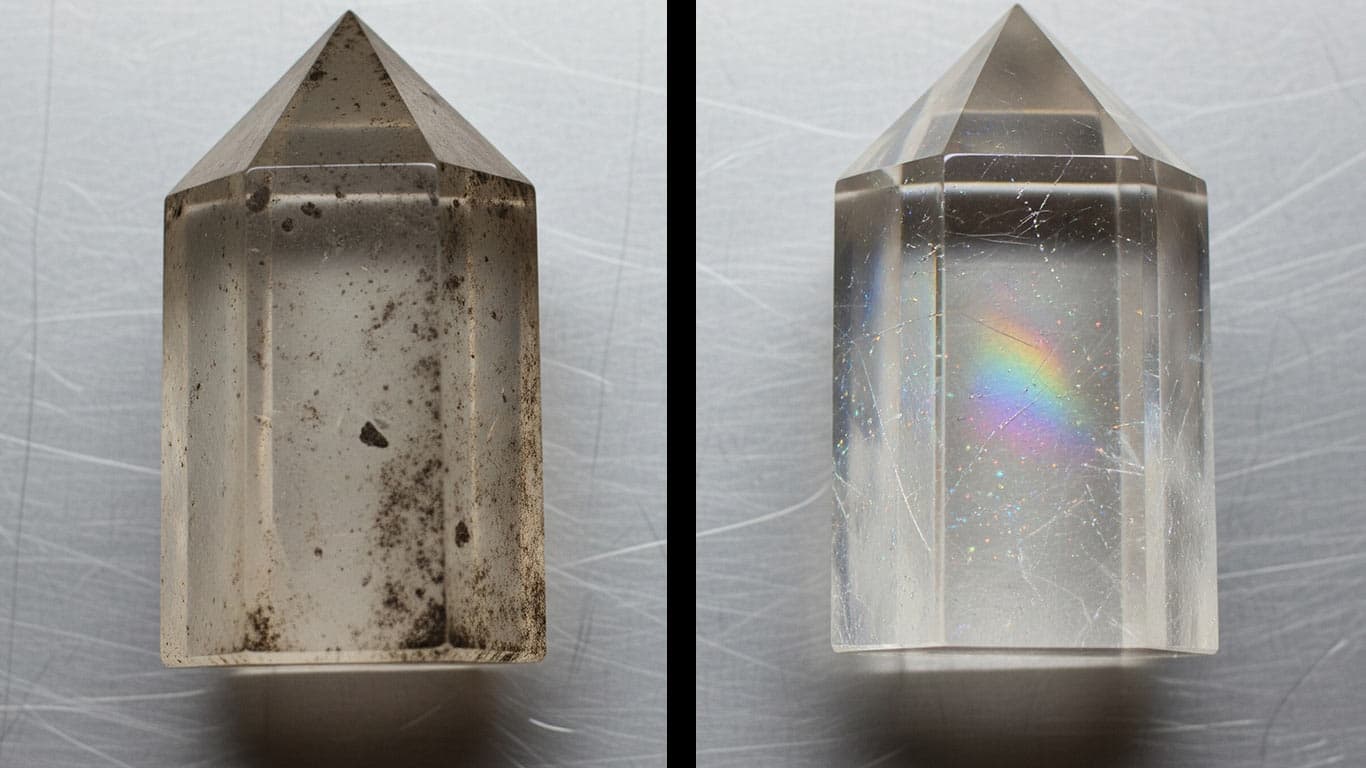

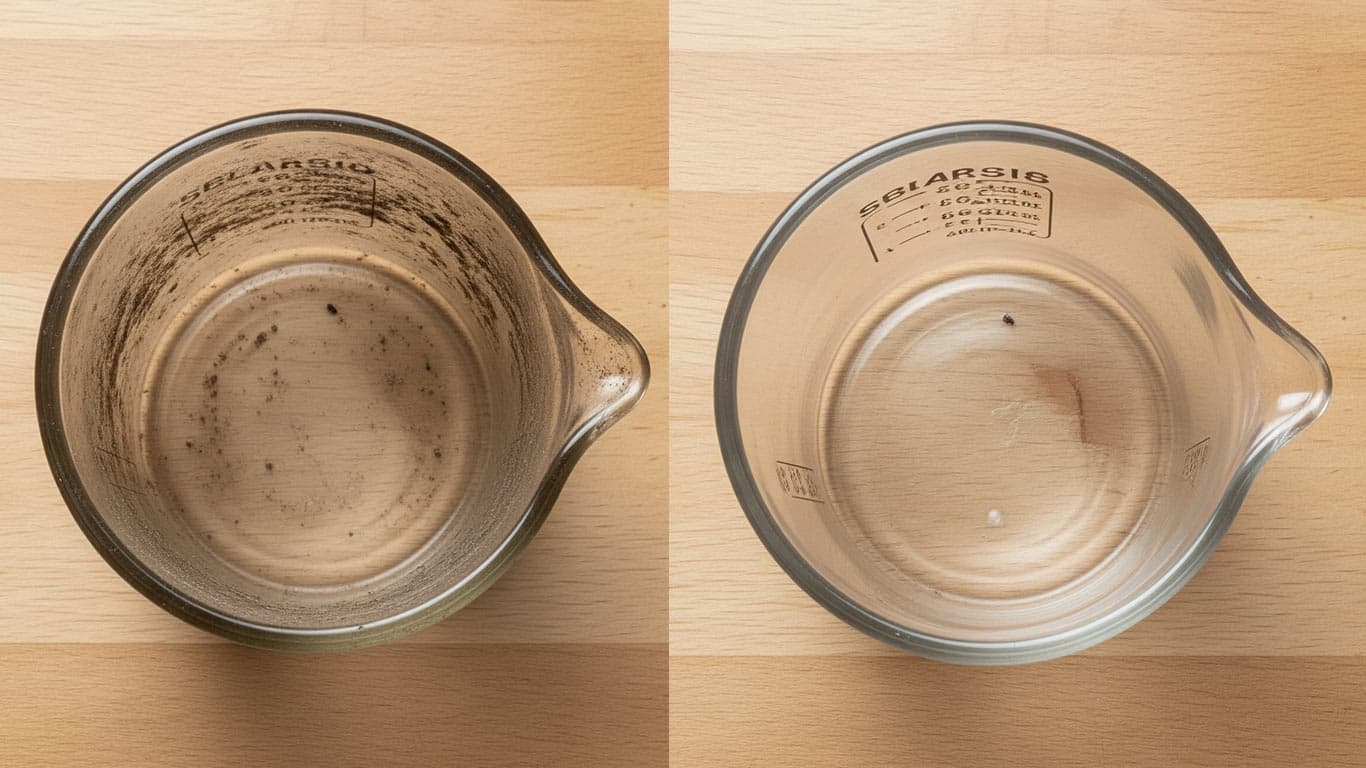

Fertilizer Salt Deposits

Fertilizer residue contamination, it forms through deposition of crystalline salts and organic compounds on industrial surfaces, influenced from environmental humidity and prolonged exposure. These residues, they exhibit unique patterns, such as irregular, patchy films that adhere tenaciously to metallic substrates, which leads to differential behaviors across materials. On ferrous alloys, the contamination manifests as hardened layers, resistant to initial laser pulses, that demonstrates persistence under thermal stress. It seems that removal challenges arise from this adhesion, dependent from the residue's hygroscopic nature, complicating uniform ablation. The process yields effective cleaning when laser parameters target these patterns, though plastics show smoother detachment compared to metals. Shows that material-specific traits, like surface porosity, influence the overall efficacy, ensuring targeted restoration without substrate damage.

Produced Compounds

Affected Materials

Aluminum

Borosilicate Glass

Brass

Brick

Bronze

Cast Iron

Ceramic Matrix Composites CMCs

Concrete

Copper

Crown Glass

Fiberglass

Float Glass

Glass Fiber Reinforced Polymers GFRP

Gorilla Glass

Granite

Iron

Lead Crystal

Limestone

Magnesium

Marble

Nickel

Porcelain

Quartz Glass

Sandstone

Sapphire Glass

Slate

Soda-Lime Glass

Stainless Steel

Steel

Tempered Glass

Terracotta

Titanium

Titanium Carbide

Tool Steel

Zinc

Aluminosilicate Glass

Titanium Alloy (Ti-6Al-4V)

Stainless Steel 316

Stainless Steel 304

Aluminum Bronze

Aluminum Nitride

Titanium Nitride

Fertilizer Salt Deposits Dataset

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more