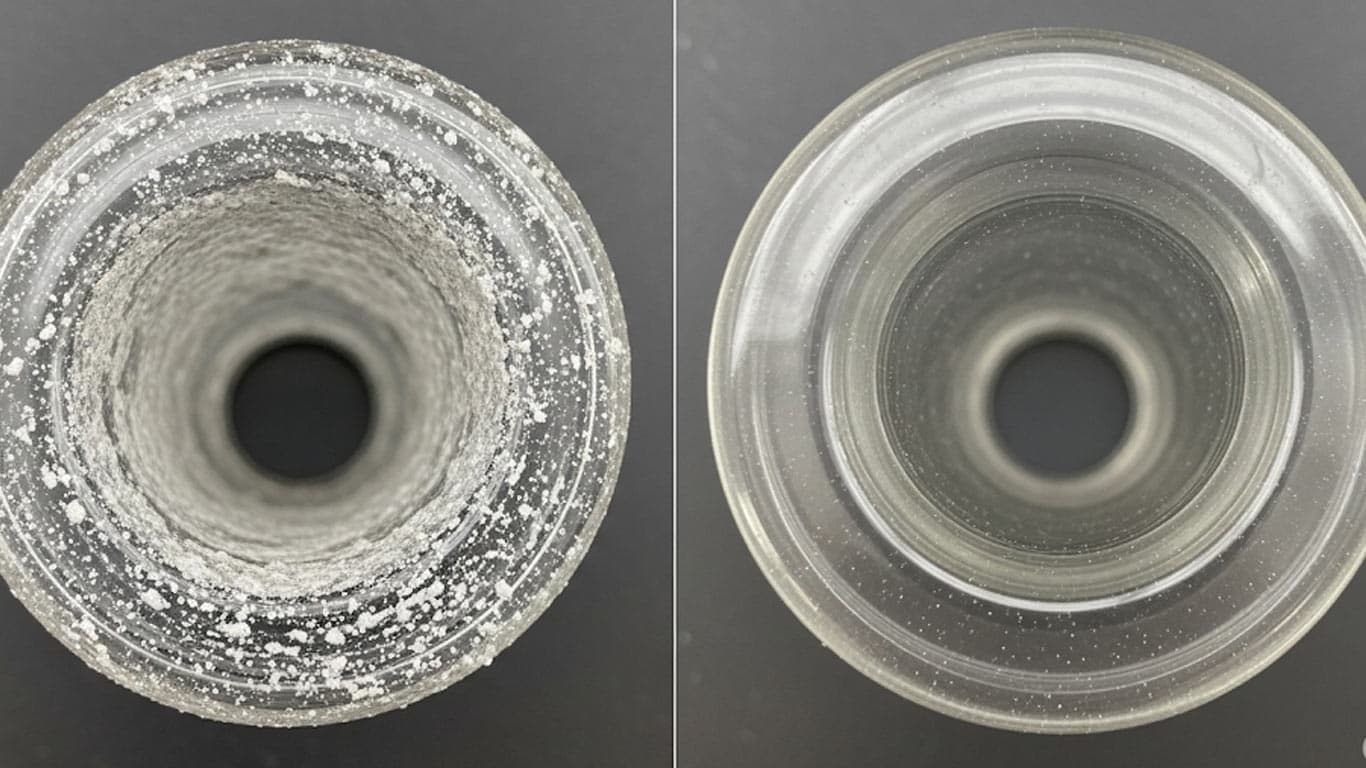

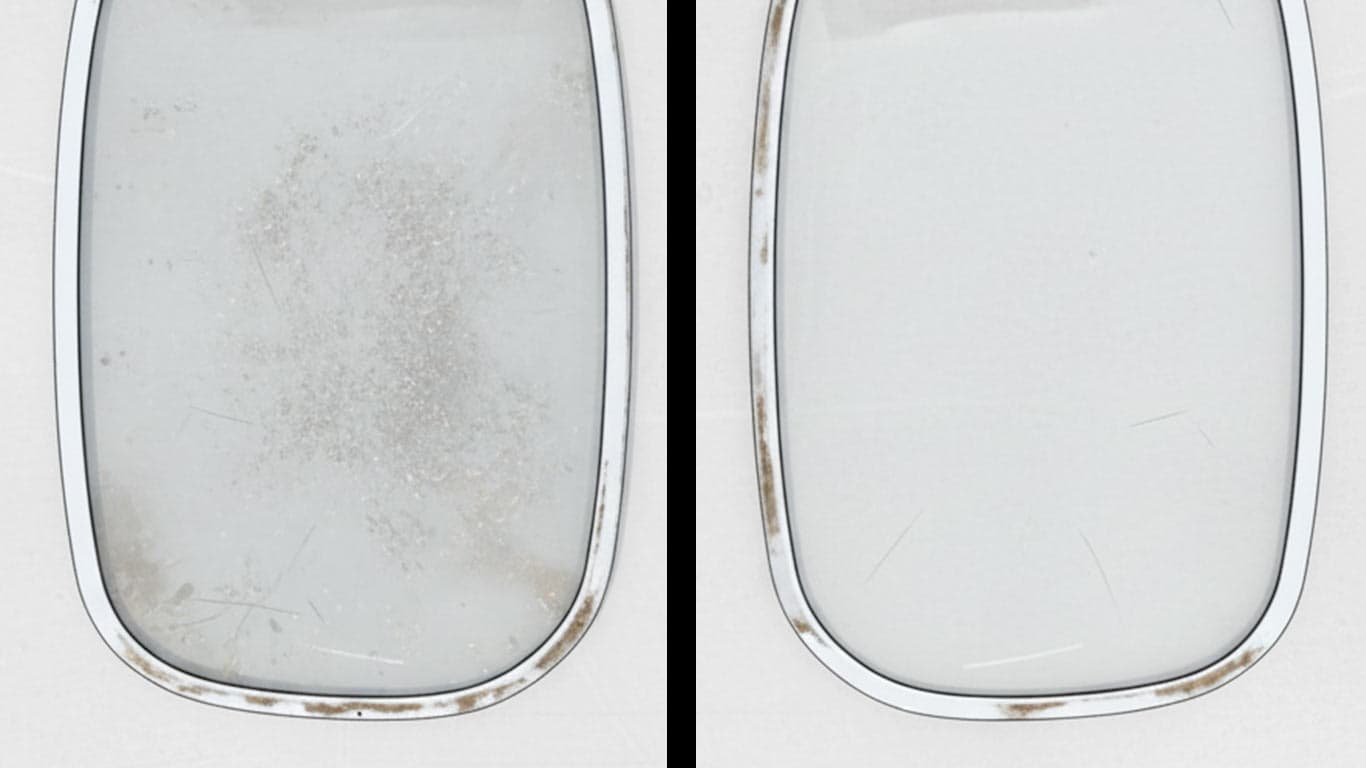

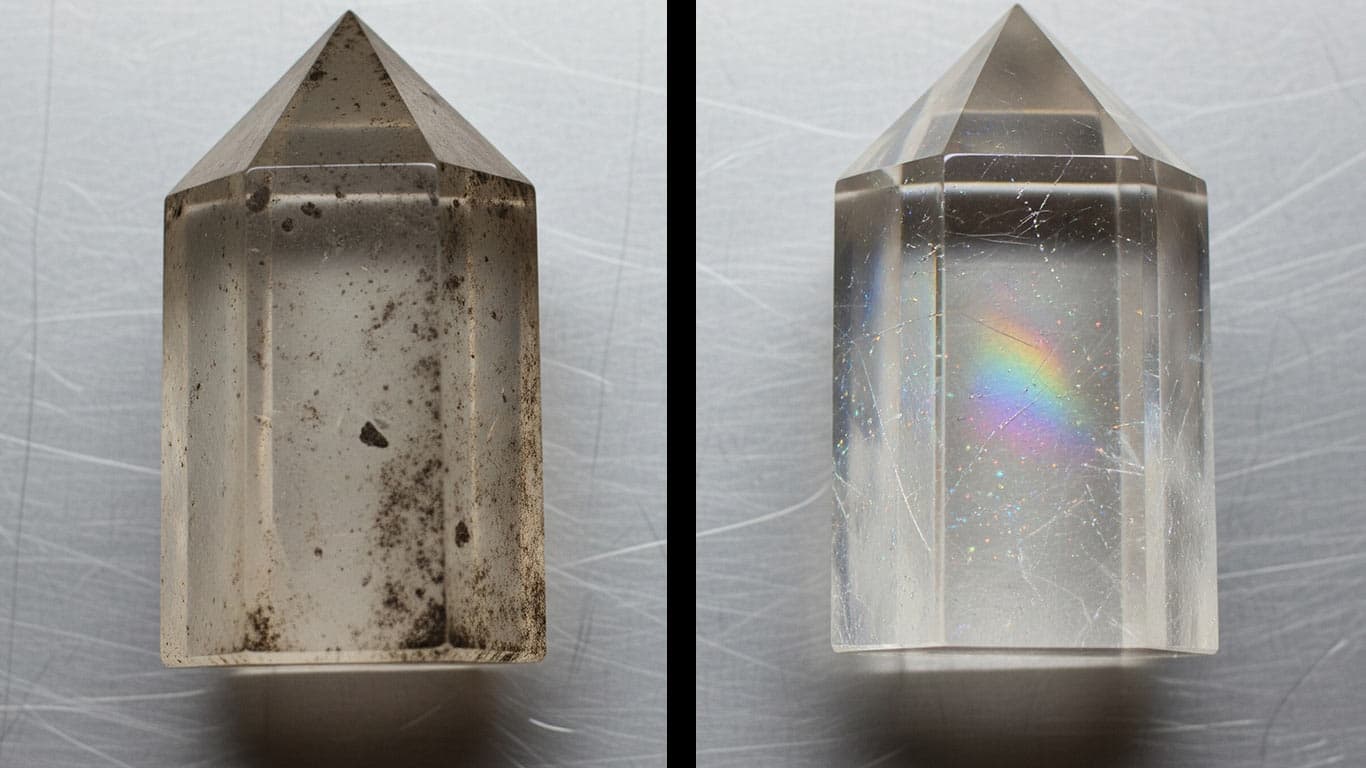

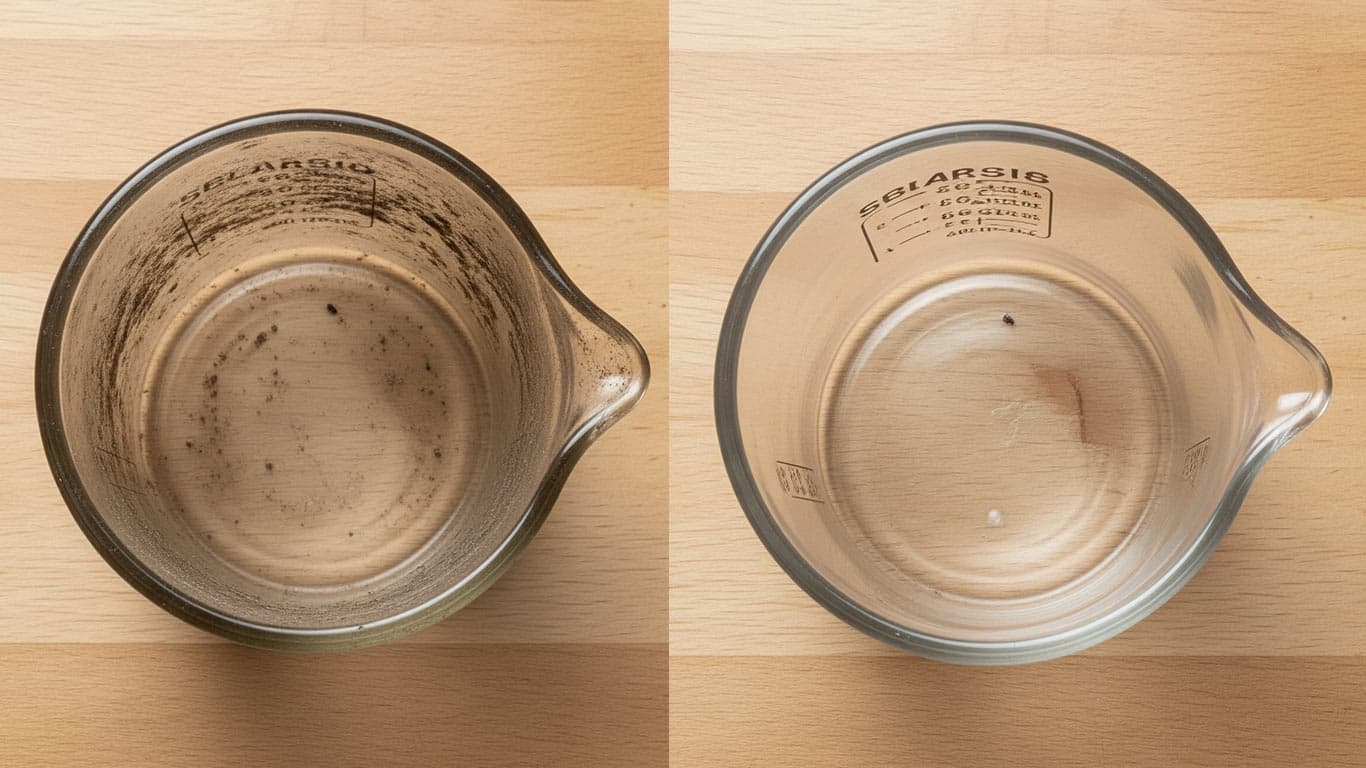

Carbon Soot Deposits

Carbon-soot contamination, it emerges from incomplete combustion processes and deposits as irregular, porous layers on material surfaces. Formation patterns reveal unique regional variations, where soot clusters in dense patches on metallic substrates and spreads thinly on polymers, thus creating uneven adhesion profiles. This contamination, it absorbs laser energy efficiently yet resists complete removal due to its volatile organic composition. Removal challenges arise from thermal gradients during ablation; soot vaporizes rapidly, and residues scatter, so secondary contamination risks increase on nearby areas. Material-specific behaviors differ markedly—on steels, soot bonds tenaciously and demands pulsed laser sequences for dislodgement, while on ceramics, it flakes off more readily following initial irradiation. After treatment, surfaces exhibit reduced roughness, yet traces persist in crevices, thus requiring multi-pass cleaning for uniformity.

Yi-Chun Lin, Ph.D., Taiwan

Produced Compounds

Affected Materials

Aluminum

Borosilicate Glass

Brass

Brick

Bronze

Cast Iron

Ceramic Matrix Composites CMCs

Concrete

Copper

Crown Glass

Fiberglass

Float Glass

Glass Fiber Reinforced Polymers GFRP

Gorilla Glass

Granite

Iron

Lead Crystal

Limestone

Magnesium

Marble

Nickel

Porcelain

Quartz Glass

Sandstone

Sapphire Glass

Slate

Soda-Lime Glass

Stainless Steel

Steel

Tempered Glass

Terracotta

Titanium

Titanium Carbide

Tool Steel

Zinc

Aluminosilicate Glass

Titanium Alloy (Ti-6Al-4V)

Stainless Steel 316

Stainless Steel 304

Aluminum Bronze

Aluminum Nitride

Titanium Nitride

Carbon Soot Deposits Dataset

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more