Bitumen and Tar Coatings

Bitumen-tar contamination forms sticky organic residue on surfaces during industrial exposure and road contact. Layer adheres strongly because it penetrates pores and creates uneven buildup. After deposition, surface exhibits dark, viscous coating that resists initial cleaning. In laser applications, removal challenges arise so thermal expansion causes cracking but re-adhesion occurs. Material behaviors differ: on metals, tar carbonizes easily and produces smoke, while on stone, bitumen softens slowly without deep penetration. Process demands pulsed lasers to avoid substrate damage. Results show effective ablation on flat areas, yet crevices trap residue for prolonged treatment. During observations, uniformity improves after multiple passes.

Produced Compounds

Affected Materials

Aluminum

Brass

Brick

Bronze

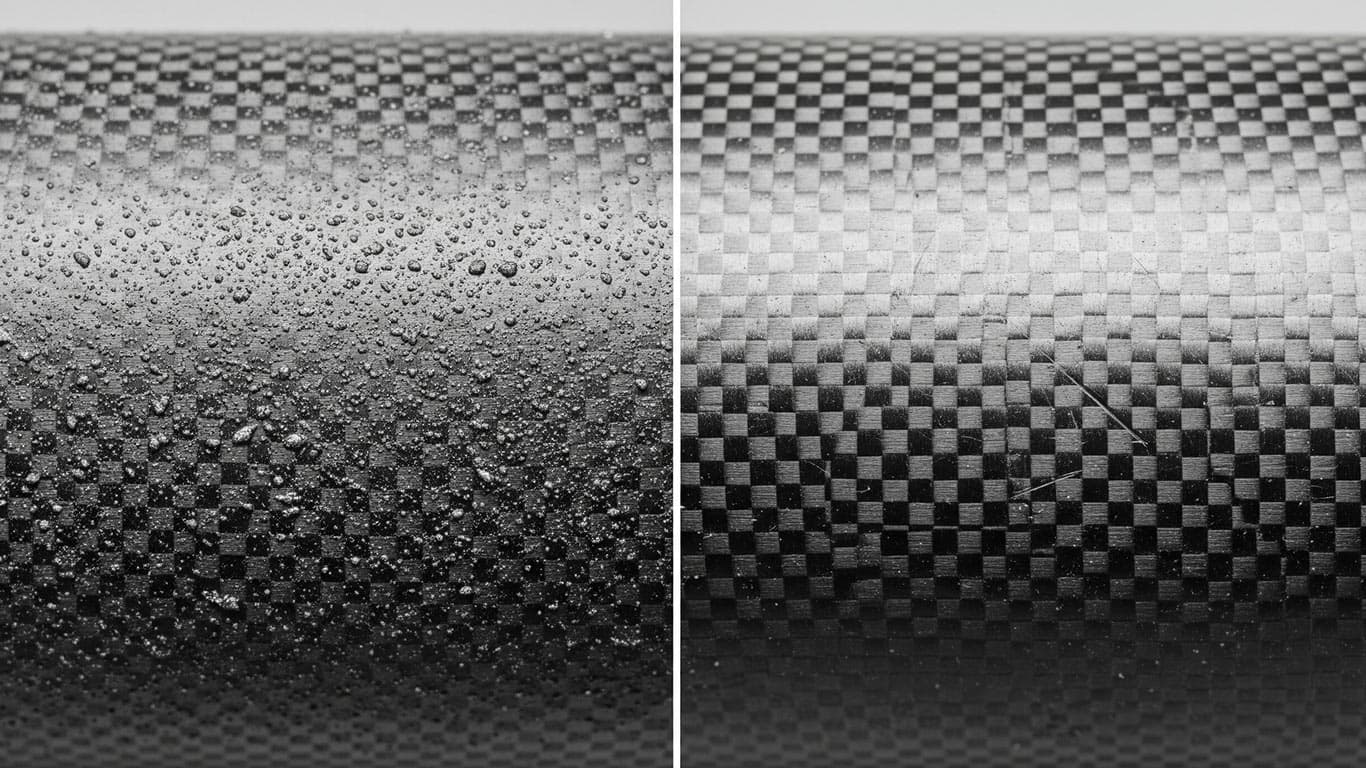

Carbon Fiber Reinforced Polymer

Cast Iron

Ceramic Matrix Composites CMCs

Concrete

Copper

Epoxy Resin Composites

Fiberglass

Granite

Iron

Limestone

Magnesium

Marble

Metal Matrix Composites MMCs

Nickel

Phenolic Resin Composites

Polyester Resin Composites

Porcelain

Sandstone

Slate

Stainless Steel

Steel

Terracotta

Titanium

Titanium Carbide

Tool Steel

Urethane Composites

Zinc

Titanium Alloy (Ti-6Al-4V)

Stainless Steel 316

Stainless Steel 304

Aluminum Bronze

Aluminum Nitride

Titanium Nitride

Bitumen and Tar Coatings Dataset

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more