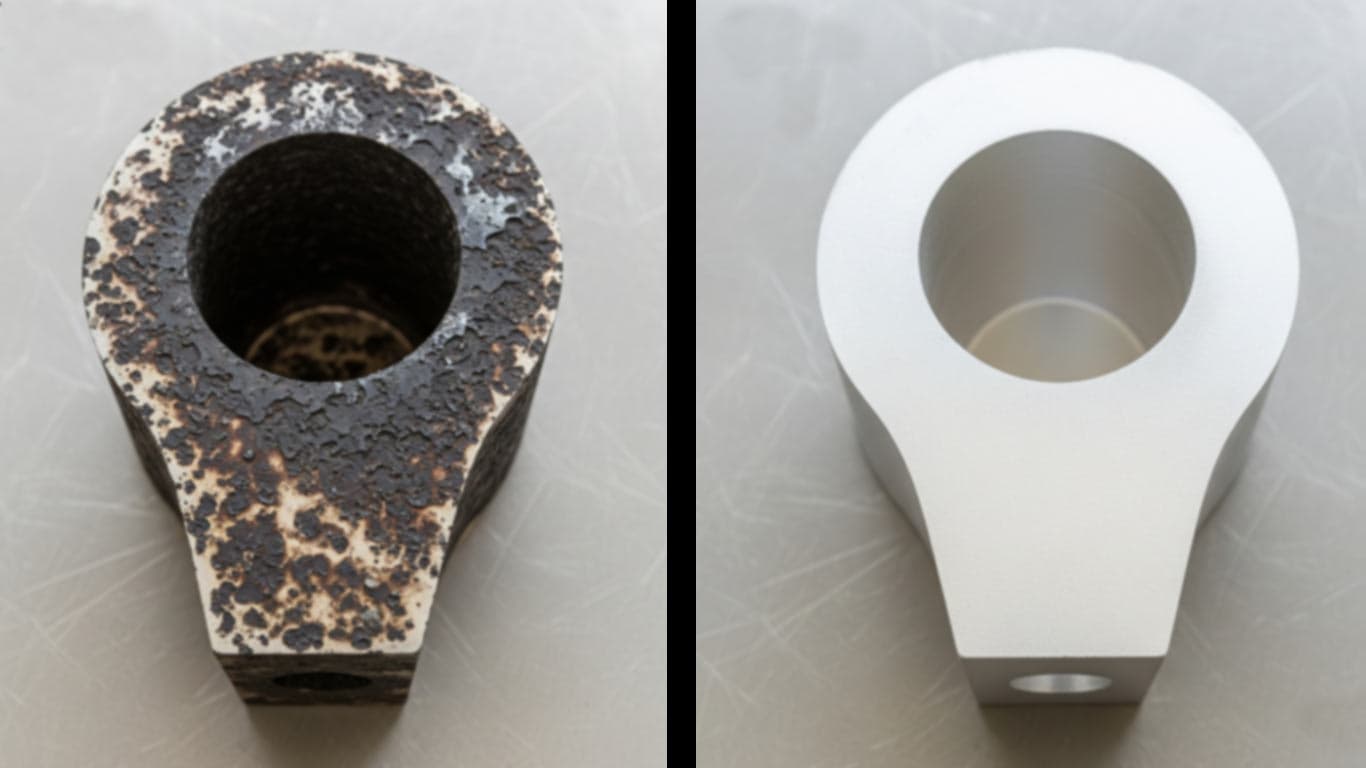

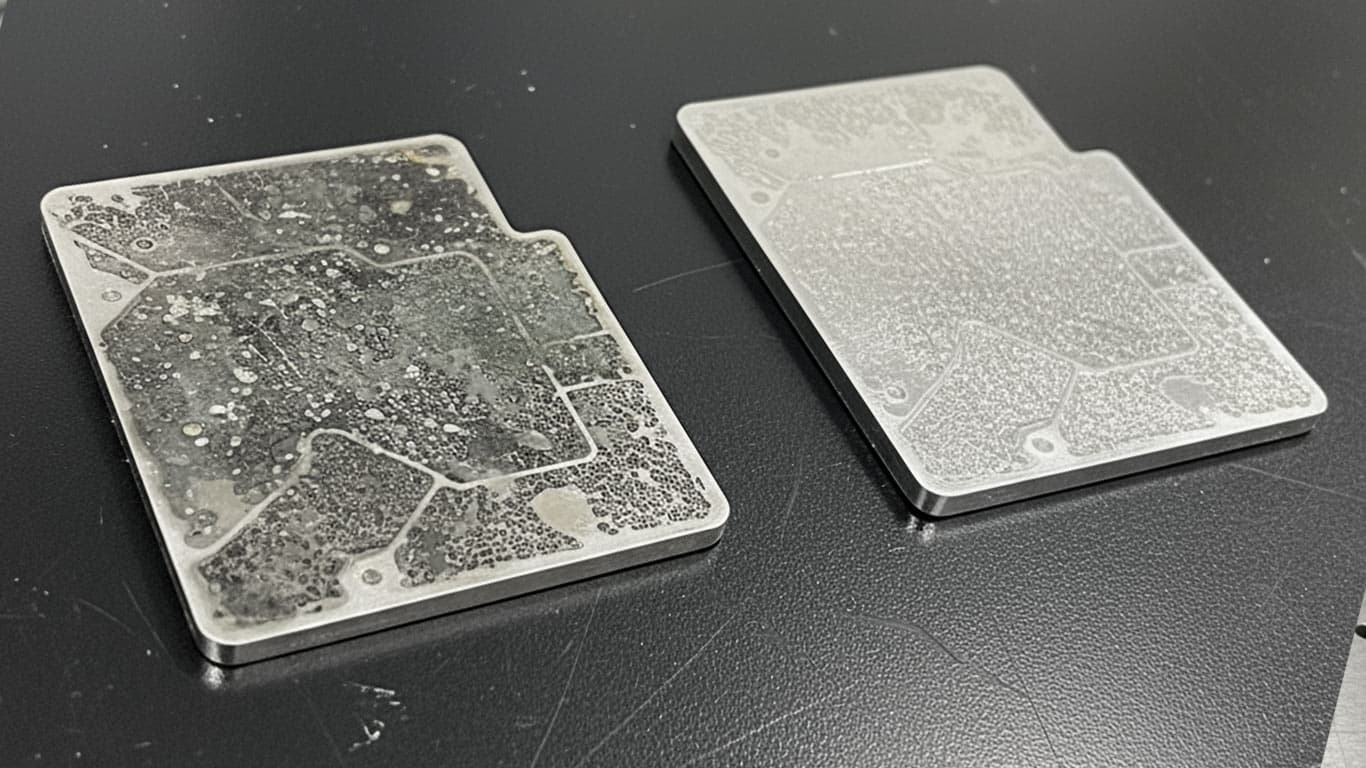

Bronze Patina and Corrosion

Bronze patina contamination, it arises from oxidation on bronze surfaces. Exposure to air and moisture causes this. Layer forms unevenly, with green hues dominating. Unique patterns emerge regionally—natural variations show thicker deposits in humid areas and thinner ones in dry spots. This contamination, it adheres strongly to alloy structure. Material-specific behaviors reveal challenges; bronze's copper content accelerates patina growth, and tin elements make it porous. Removal in laser cleaning demands precision. Laser pulses target layer, but heat buildup risks substrate damage. After treatment, surface still shows residues if fluence adjusts poorly. Challenges follow: patina resists ablation due to its density, thus multiple passes become necessary. Process yields cleaner finish, yet overexposure etches metal. Efficiency of cleaning, it depends on wavelength selection. Contamination removal confirms patina's durability—evidence from tests establishes careful parameter control as key. Bronze responds uniquely, so operators must monitor patterns closely.

Produced Compounds

Affected Materials

Bronze Patina and Corrosion Dataset

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more