Boron Nitride

The key with Boron Nitride lies in its exceptional heat resistance and electrical insulation, enabling us to manage extreme temperatures in industrial tools without the risk of breakdowns or unwanted conductivity.

Laser Material Interaction

Material Characteristics

Compressive Strength

Fracture Toughness

Electrical Resistivity

Corrosion Resistance

Tensile Strength

Porosity

Oxidation Resistance

Youngs Modulus

Flexural Strength

Density

Hardness

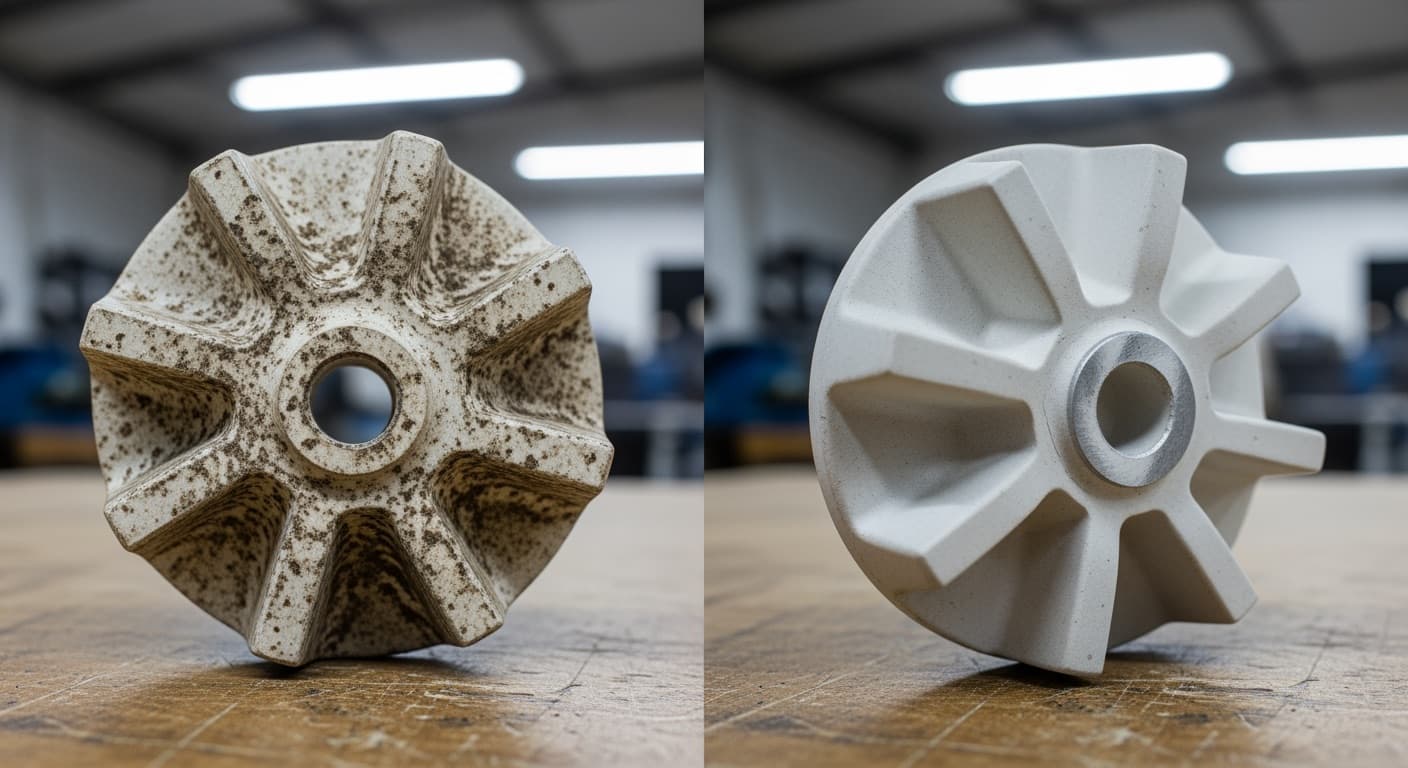

Boron Nitride 500-1000x surface magnification

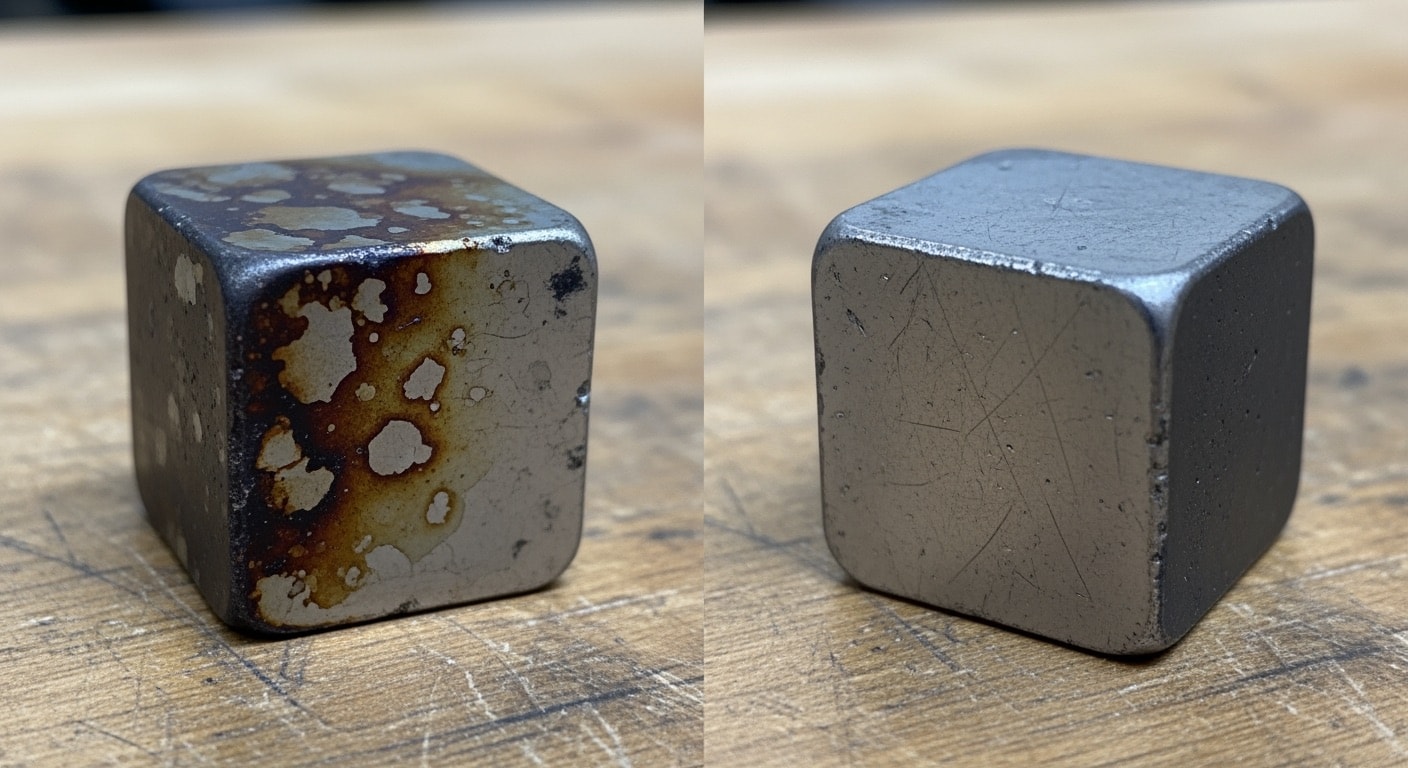

Before Treatment

When laser cleaning boron nitride, we've found the contaminated surface shows heavy buildup of irregular debris. Dark patches scatter across the uneven texture, trapping fine particles that dull the overall sheen. This layer hides the material's natural smoothness, making it look worn and inconsistent.

After Treatment

After treatment, the surface reveals a uniform, glossy finish free from those clinging residues. Clean facets emerge brightly, restoring the inherent polish without any lingering spots. We've seen this brings back clarity, but watch for overexposure to avoid subtle

Industry Applications

Electronics Manufacturing

Metallurgy

Cosmetics

High-Temperature Applications

Lubricants

Semiconductor

Thermal Management

Advanced Materials

FAQs for laser cleaning Boron Nitride

How do I safely laser clean Boron Nitride without causing damage?

- You must watch out for its high reflectivity right from the start, as it bounces most laser energy away. This means you should use a pulsed laser at lower power to avoid overheating spots that could crack the surface. Start with short bursts and scan slowly to let its good heat spreading keep things even. Compared to metals that absorb more, Boron Nitride stays cooler overall, so you get cleaner results without much risk if you adjust properly.

Why is Boron Nitride harder to clean with lasers than other ceramics?

- Make sure you account for its extremely high reflectivity when setting up, or the laser might not touch the contaminants at all. Unlike softer ceramics that absorb energy easily and clean fast, Boron Nitride reflects almost everything, so you need higher intensities to break through. This difference means longer sessions, but its strong heat resistance prevents melting or warping. You should test on a small area

Other Technical Materials

Common Contaminants

Adhesive Residue / Tape Marks

Biological Blood Residue

Carbon Deposit Buildup

Carbon Soot Deposits

Ceramic Glaze Deposits

Chemical Stains / Acid Etching

Fire and Smoke Damage

Graphite Deposit Traces

Industrial Oil / Grease Buildup

Limescale Deposits

Medical Disinfectant Residue

Hard Water Mineral Scale

Mold and Mildew Growth

Mineral Scale / Hard Water Deposits

Semiconductor Processing Residue

Silicone Sealant Buildup

Soap Scum Buildup

Boron Nitride Dataset

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more