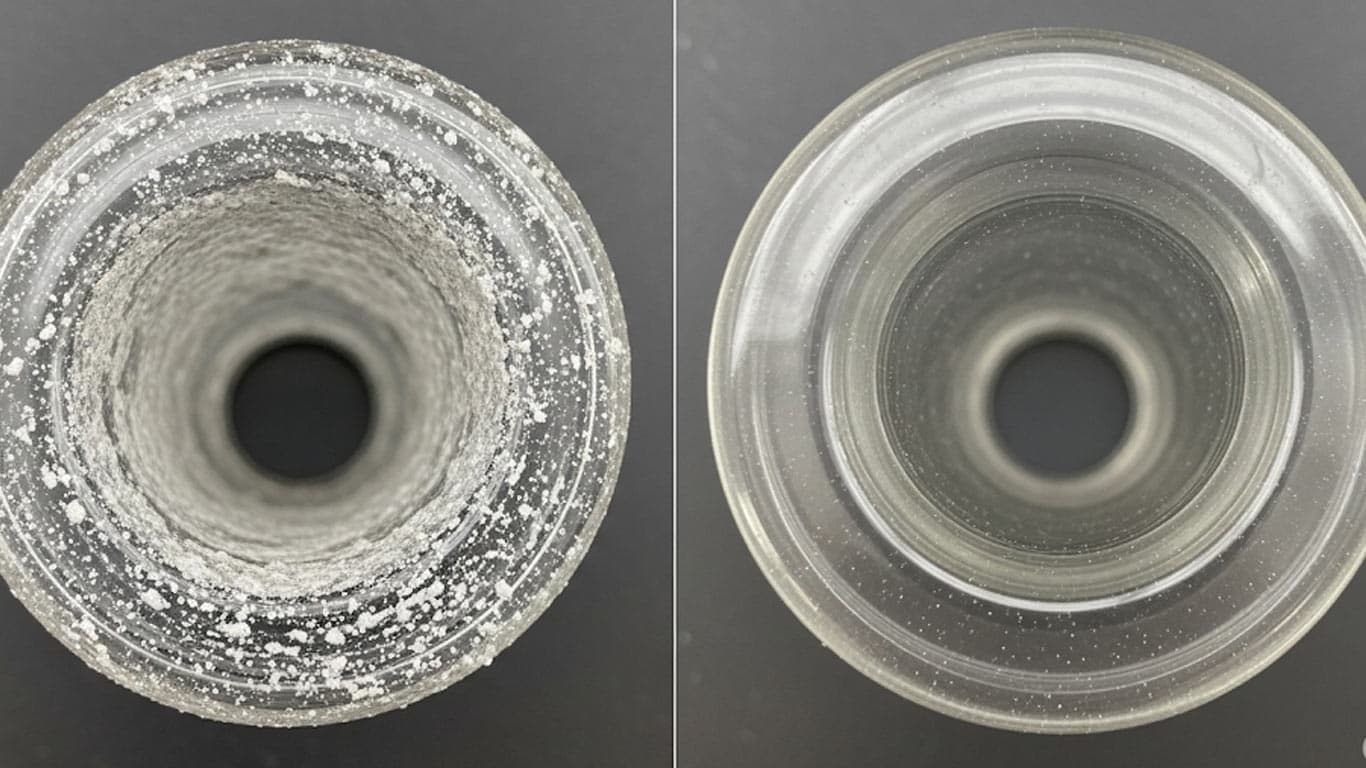

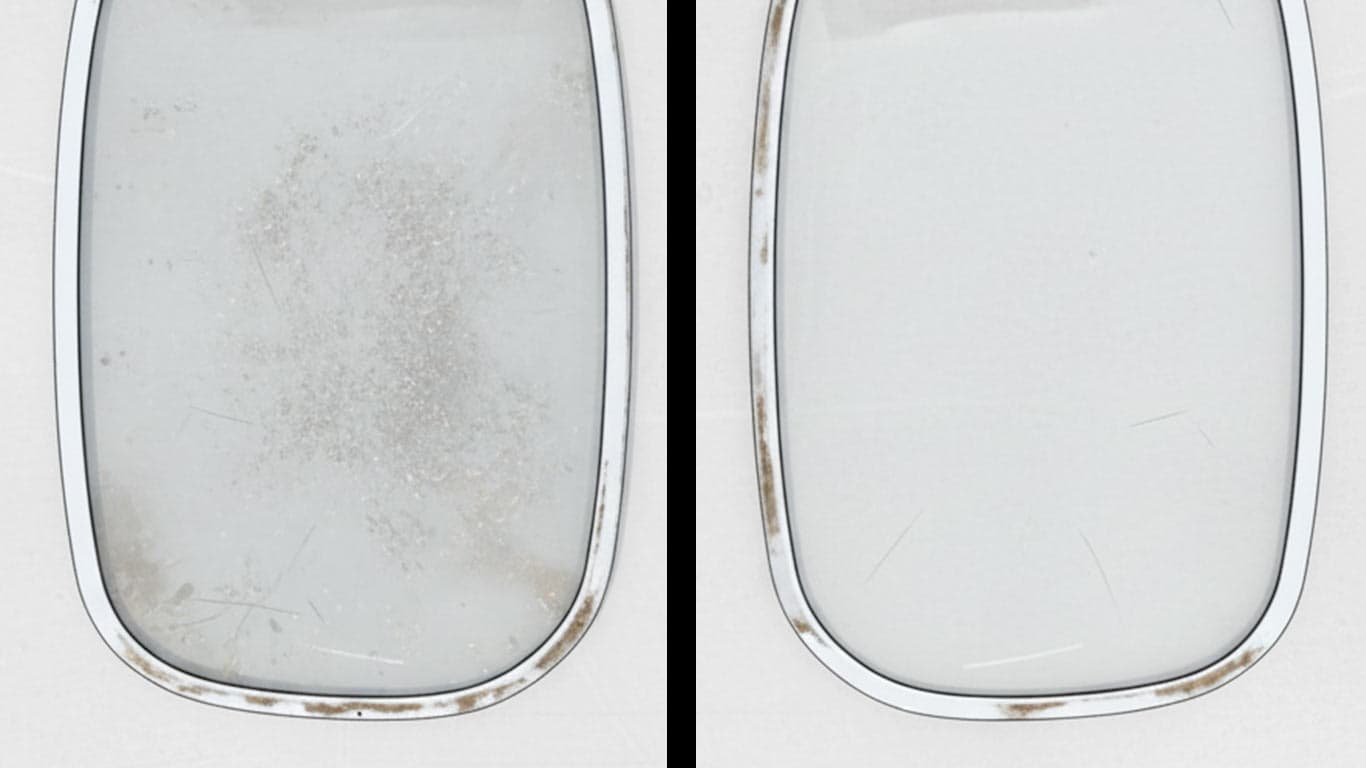

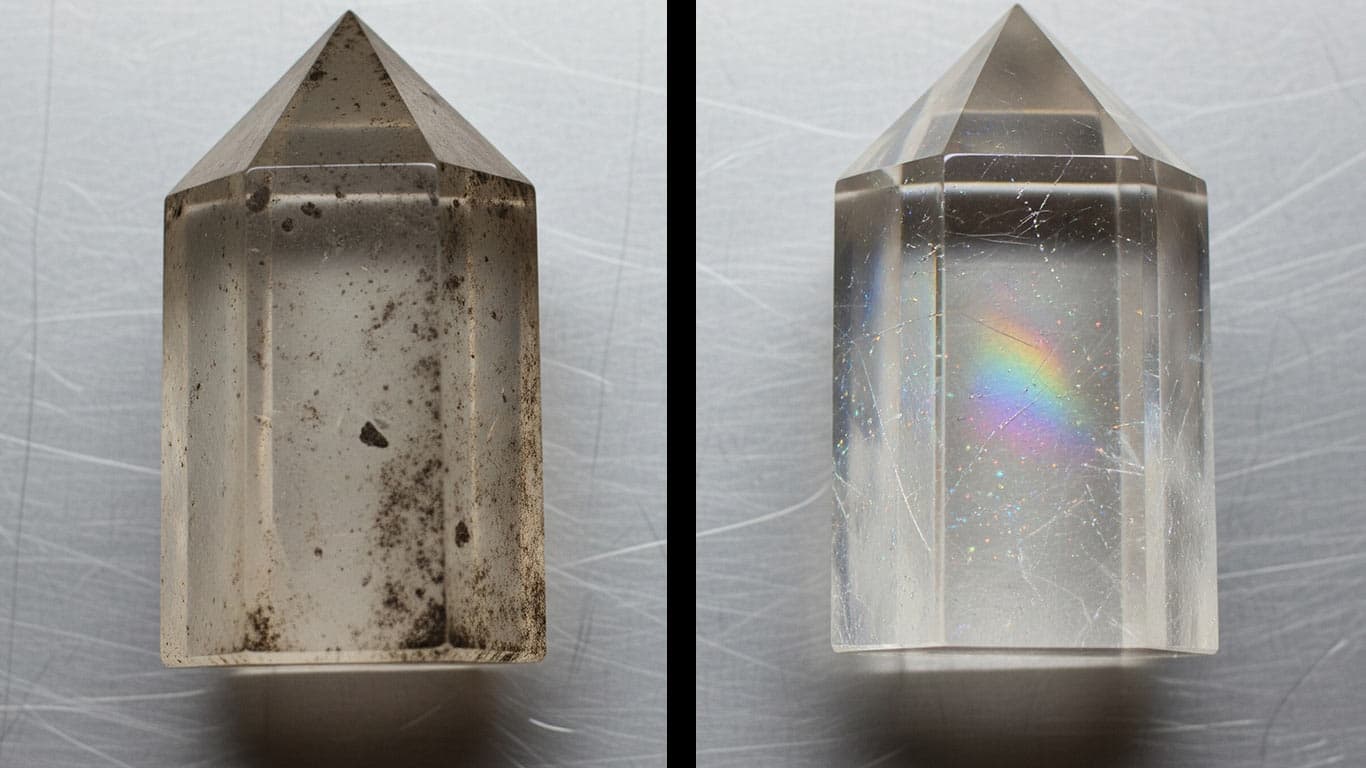

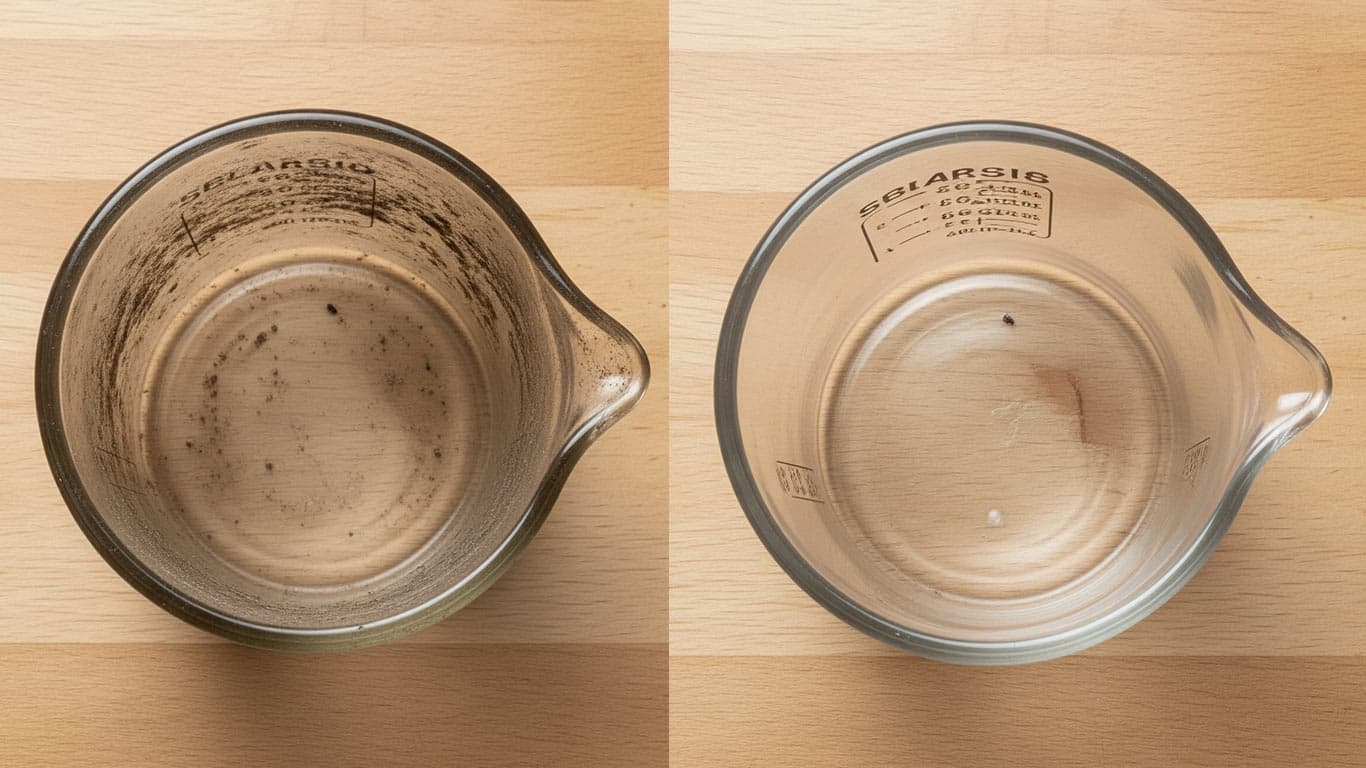

Limescale Deposits

Lime scale contamination builds up as hard, chalky deposits from mineral-rich water, forming irregular layers on metal and stone surfaces in humid environments. These patterns often show flaky, uneven crusts that cling tightly, especially around joints or heat-exposed areas, creating a significant challenge for laser cleaning. Lasers effectively vaporize the scale, but the process demands precise control to avoid thermal damage underneath. On stainless steel, it removes cleanly with minimal residue, while on porous stone, it risks cracking if energy ramps up too quickly. In practice, operators dial in lower intensities first, which clears the buildup without harming the base material. Overall, this contamination responds well to pulsed lasers, achieving a clean finish while preserving surface integrity.

Produced Compounds

Affected Materials

Aluminum

Borosilicate Glass

Brass

Bronze

Cast Iron

Concrete

Copper

Crown Glass

Fiberglass

Float Glass

Glass Fiber Reinforced Polymers GFRP

Gorilla Glass

Granite

Iron

Lead Crystal

Limestone

Magnesium

Marble

Nickel

Quartz Glass

Sandstone

Sapphire Glass

Slate

Soda-Lime Glass

Stainless Steel

Steel

Tempered Glass

Titanium

Titanium Carbide

Tool Steel

Zinc

Aluminosilicate Glass

Titanium Alloy (Ti-6Al-4V)

Stainless Steel 316

Stainless Steel 304

Aluminum Bronze

Aluminum Nitride

Titanium Nitride

Limescale Deposits Dataset

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more