Yttria-Stabilized Zirconia

Yttria-Stabilized Zirconia exhibits exceptional hardness and thermal stability, which renders it suitable for laser cleaning applications. This ceramic, it resists oxidation tenaciously, enabling precise contaminant removal without damage. Yet, its toughness, that demands careful beam control, presents processing challenges.

Laser Material Interaction

Material Characteristics

Youngs Modulus

Corrosion Resistance

Fracture Toughness

Porosity

Electrical Resistivity

Compressive Strength

Density

Hardness

Tensile Strength

Flexural Strength

Yttria-Stabilized Zirconia 500-1000x surface magnification

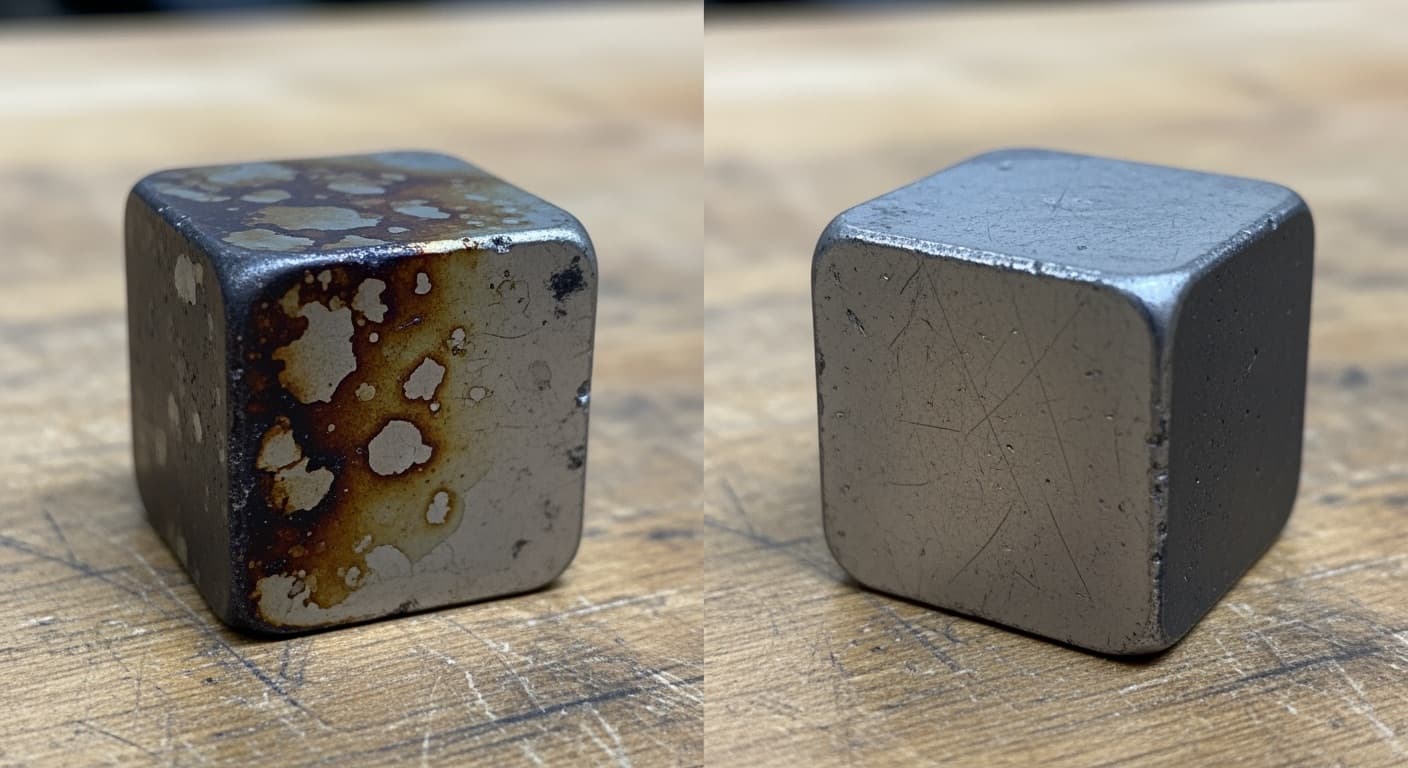

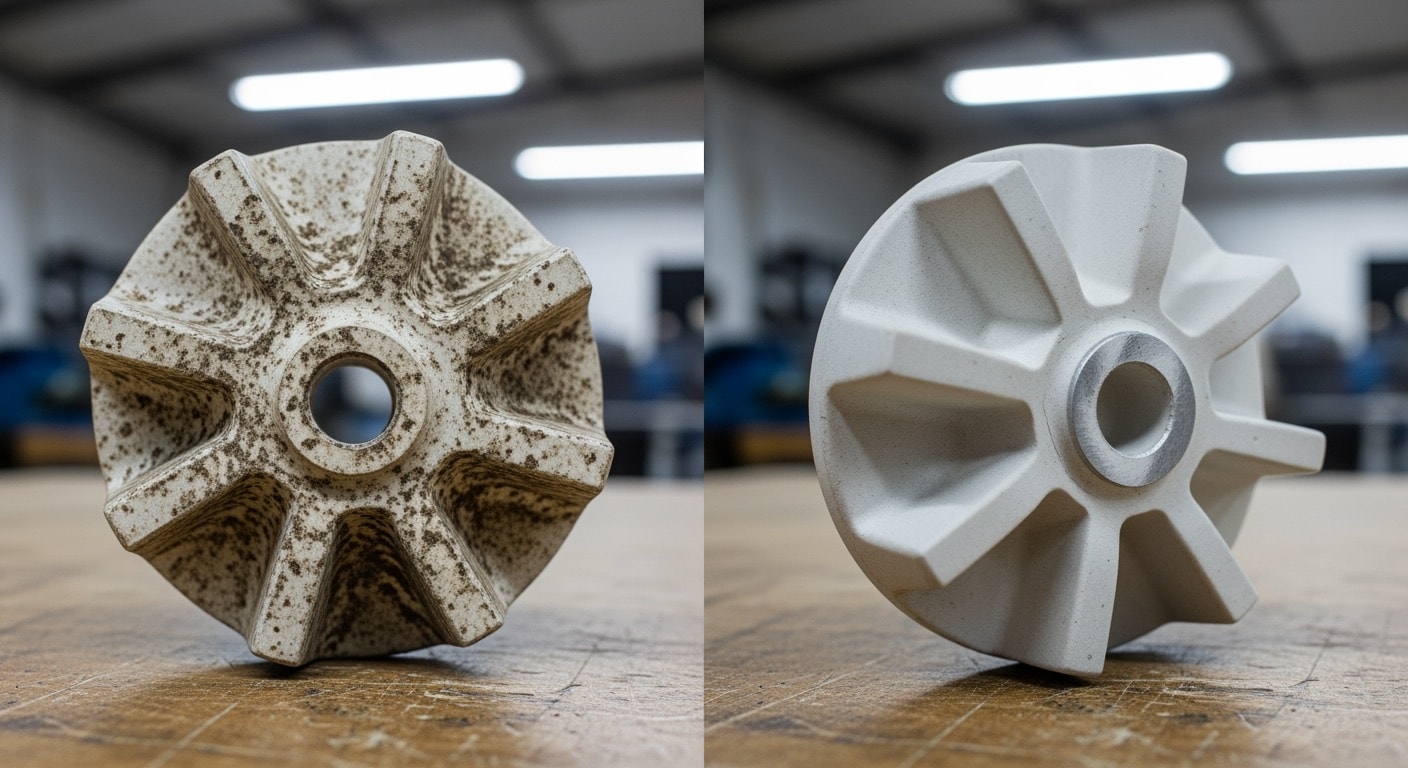

Before Treatment

We've found the contaminated surface looks rough and uneven under magnification. Dirt clings tightly to the grains, creating dark spots everywhere. It hides the material's true texture completely.

After Treatment

After laser treatment, the surface appears smooth and uniform now. Grains stand out clearly without any residue left. This reveals the clean, even finish underneath.

Industry Applications

Dental Implants

Medical Devices

Thermal Barrier Coatings

Aerospace

Automotive

High-Temperature Applications

Fuel Cells

Advanced Ceramics

FAQs for laser cleaning Yttria-Stabilized Zirconia

How do I safely laser clean YSZ without causing cracks?

- I've seen YSZ hold up well during cleaning if you start slow. Begin with low power to gently remove dirt and oxides from the surface. Watch the heat buildup closely, as this material resists thermal shock but can crack under sudden changes. Keep the beam moving steadily to avoid hot spots. This approach brings back the clean finish every time.

What's the best way to remove contaminants from YSZ coatings?

- When cleaning YSZ, focus on a pulsed laser setup first. This works well because the material's toughness lets it handle short bursts without damage. I've found scanning in overlapping passes removes stubborn buildup like soot effectively. Adjust speed based on layer thickness to ensure even results. Tends to restore the original smooth texture nicely.

Can laser cleaning affect YSZ's thermal properties long-term?

- Start by testing a small area to check response. YSZ's stability means cleaning rarely alters its heat resistance over time

Other Technical Materials

Common Contaminants

Adhesive Residue / Tape Marks

Biological Blood Residue

Carbon Deposit Buildup

Carbon Soot Deposits

Ceramic Glaze Deposits

Chemical Stains / Acid Etching

Fire and Smoke Damage

Graphite Deposit Traces

Industrial Oil / Grease Buildup

Limescale Deposits

Medical Disinfectant Residue

Hard Water Mineral Scale

Mold and Mildew Growth

Mineral Scale / Hard Water Deposits

Semiconductor Processing Residue

Silicone Sealant Buildup

Soap Scum Buildup

Yttria-Stabilized Zirconia Dataset

License: Creative Commons BY 4.0 • Free to use with attribution •Learn more